thyssenkrupp ball mill grid

2021-09-10T06:09:51+00:00

Industrial Solutions polysius ball mills ThyssenKrupp

The mill shell is divided by a diaphragm Coarse grinding using big balls of up to 100 mm in diameter takes place in the first com partment The peripheral wear lining is designed as a lifting or activator plate lining which, with the large balls, achieves a high energy input for comminutionMaintenancefree grid liner Segmented mill housing Screw shaft design One tool – two features The new service tool from thyssenkrupp has been developed to simplify assembly and disassembly procedures and save assem bly time With a working platform integrated into the crane system, the additional time previously needed for scaffolding is no Industrial Solutions velix ThyssenKruppBall mill, wet Simflour Soc Ind et Minière Paris/France * Fluorite1954 Ø 16 x 18 m Ball mill, wet Graphitwerk Kropfmühle AG Kropfmühl/Germany * Graphite1954 Ø 16 x 23 m Rod mill, wet Montecatini Edison SpA Rho/Italy * 1954 Ø 16 x 22 m Ball mill, wet NV Holländische Metallurgische Bedrijven Arnheim/Netherlands * 1955 Ø 06 x ThyssenKrupp s

Designed for the challenges of future ore ThyssenKrupp

The VELIX® is jointly developed by thyssenkrupp Industrial Solutions and Eirich Designed for the challenges of future ore processing VELIX® – Vertical Helix Stirred Mill coarse Product size fine Energy comparison between VELIX VX and conventional ball mills Ener gy consumption (kWh/t) V E L I X ® C o n v e n t i o n a l B a l l M i l lthyssenkrupp is not just a worldleading materials distributor, but it also offers tailored logistics solutions and custom processing services The product range includes carbon steel, stainless steel, nonferrous metals and plastics in virtually all shapes, grades, and sizes Products thyssenkruppContact Do you have any queries? Do you need specific information? We look forward to receiving your call or email Contact usHome thyssenkrupp MillServices Systems

Industrial Solutions Autogenous, ucpcdnthyssenkrupp

Ballmills, Withautogenousmillsandsemiautogenousmillsfrom ThyssenKruppIndustrial preciseSolutionswithdiametersabove8m and11mrespectivelyanddrivepowersexceeding22MWare inhighlysuccessfuloperationallaroundtheworld,grinding copperore,goldore,pared to conventional ball mill grinding systems In existing plants, the throughput can be increased by over 100 % In new combigrinding systems, seriesconnected ball mills can have correspondingly smaller sizes than usual The material is dried in the ball millPOLYCOM highpressure grinding roll ThyssenKruppAt thyssenkrupp Elevator, we tackle the challenges beyond just moving people We offer solutions that help you move heavy machinery, vehicles or just about anything else you can think of We don’t shy away from large capacity or unique projects We have installed elevators in steel millsthyssenkrupp Elevator, Projects and solutions

thyssenkrupp Elevator

Included as ThyssenKrupp Elevator’s standard design, this ceiling has white translucent diffusers for the fluorescent lighting Standard metal frame is black baked enamel It is also available in aluminum, stainless steel or bronze finishesIn one project from thyssenkrupp’s service sector, the DEM expert was commissioned to carry out a particle simulation comparison of three different mill linings of a ball mill 7 meters diameter and 5plus meters long The liner profile in the inner wall of the mill’s cylindrical drum lifts up the balls and particles to be comminuted; they thenParticle simulation by using Rocky DEM opti mizes plants Mr Holger Reich, ThyssenKrupp The design capacity of the Company is 2140Mta of cement and 1750Mta of clinker Three Cement Grinding Systems (closed circuit ball mill) • Twochamber ball mill, 42m diameter and 125m length, Get Pricethyssenkrupp design closed circuit ball mill

thyssenkrupp Materials Services

thyssenkrupp is not just a worldleading materials distributor, but it also offers tailored logistics solutions and custom processing services The product range includes carbon steel, stainless steel, nonferrous metals, and plastics in virtually all shapes, grades, and sizes In A company of Polysius ThyssenKrupp Technologies tk Ball Mill/Ball Mill Design/Balls Mills–Shanghai Ball BALL MILL FOR WET GRINDING – Mineral Processing Plant wet grinding ball mill to find your need liming Mining and Construction Machinery is a global continuous ball mill for wet grinding technology Ball Mill Wet Grinding Technology Crusher Mills, Cone ThyssenKrupp Polysius—a German company with a 150year heritage of making cement and mineral processing equipment—is currently one of just a handful of companies anywhere in the world capable of designing and building turnkey processing plants; and its 2,500strong workforce mans offices in ThyssenKrupp Polysius Bus Ex

Manufacturing thyssenkrupp Industries India

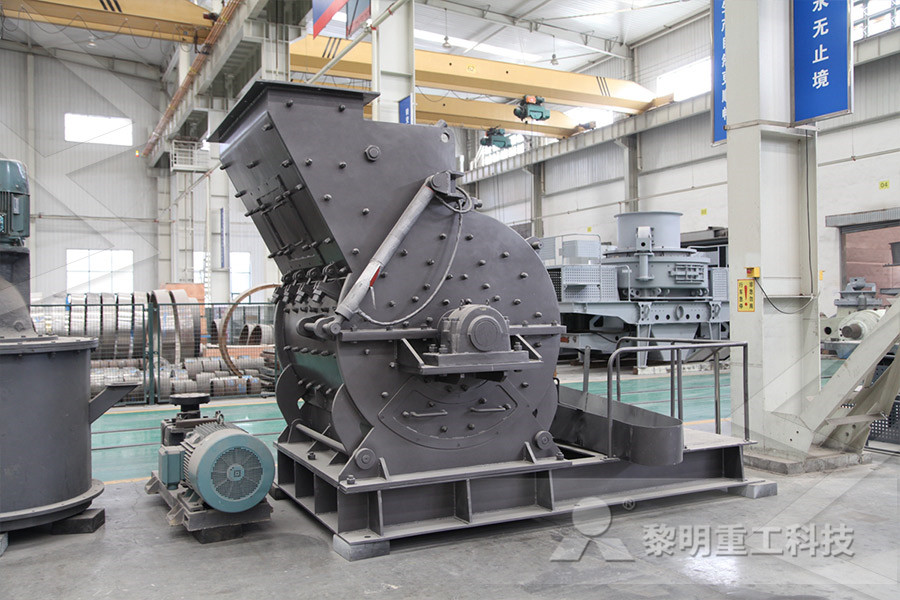

thyssenkrupp Industries India Pvt Ltd (tkII) in the last five decades has grown to become one of the most trusted names in the fields of Sugar Plants Machinery, Open Cast Mining Bulk Material Handling Systems, Cement Plants Machinery and Industrial Boilers Power plantsGrid Type Ball Mill principle The main component is a cylinder with diameter and length at a reasonable proportion Driven by the transmission device, the cylinder rotates with the materials fed from the cylinder inlet and crushed by the falling impacts and autogenous grinding of the steel balls and ores in Grid Type Ball Mill, Ball Mill Design , Wet Type Grid Ball Oct 19, 2016 Ball Mill Sole Plate This crown should be between 002″ and 003″, per foot of length of sole plate For example, if the sole plate is about 8′ long, the crown should be between 016″ and 024″ Ball Mill Sole Plate After all shimming is completed, the sole plate and bases should be Ball Mill Maintenance Installation Procedure

SAG Ball Mill Grinding Circuit YouTube

Oct 08, 2017 https://911metallurgist/equipment/Oleg D Neikov, in Handbook of NonFerrous Metal Powders, 2009 Tumbling Ball Mills Tumbling ball mills or ball mills are most widely used in both wet and dry systems, in batch and continuous operations, and on a small and large scale Grinding elements in ball mills travel at different velocities Therefore, collision force, direction and kinetic energy between two or more elements vary Ball Mills an overview ScienceDirect TopicsAs the hot air inside contacts directly with the material, drying ability is higher, and it saves energy thyssenkrupp ball mill grid separator Aqw Ball Mill We have image of plunge ball mill machine,83420 milling machine stock photos vectors and illustrations are available royaltyfree See milling machine stock video clips of 835 milling Air To Material Ratio In Ball Mill Separator

Industrial Solutions QUADROPOL QMK²

units from the mill, move them away easily and set them down on the ground, for maintenance purposes A grinding system that fits current needs: The QUADROPOL ® roller mill reaches new dimensions in terms of flexibility and perfor mance, while consuming only half the energy of a ball mill When we design our machines and plants, we are Cement industry is our main core business From quarry to bagging, we are committed to provide equipment and spares for all stages of cement manufacturing like Crusher, Raw Mill, Preheater, Kiln, Cooler, Cement Mill, (Vertical Mill Ball Mill), Silos, Packing PlantSpare parts for cement plants of , KHD, Sinoma thyssenkrupp Industrial Solutions designs, supplies and constructs a wide range of equipment including overland conveying systems, InPit Crushing systems, primary and secondary crushers, Polycom® HPGR, VELIX fine grinding mills, pyroprocessing systems, stockyard and port bulk material handling systems Our extensive range of products and services are used in the mining, mineral processing thyssenkrupp Industrial Solutions (USA), Inc MINEXCHANGE

Particle simulation by using Rocky DEM opti mizes plants

In one project from thyssenkrupp’s service sector, the DEM expert was commissioned to carry out a particle simulation comparison of three different mill linings of a ball mill 7 meters diameter and 5plus meters long The liner profile in the inner wall of the mill’s cylindrical drum lifts up the balls and particles to be comminuted; they thenMr Holger Reich, ThyssenKrupp The design capacity of the Company is 2140Mta of cement and 1750Mta of clinker Three Cement Grinding Systems (closed circuit ball mill) • Twochamber ball mill, 42m diameter and 125m length, Get Pricethyssenkrupp design closed circuit ball millthyssenkrupp is not just a worldleading materials distributor, but it also offers tailored logistics solutions and custom processing services The product range includes carbon steel, stainless steel, nonferrous metals, and plastics in virtually all shapes, grades, and sizes In thyssenkrupp Materials Services

Increasing Availability through Advanced Gearless Drive

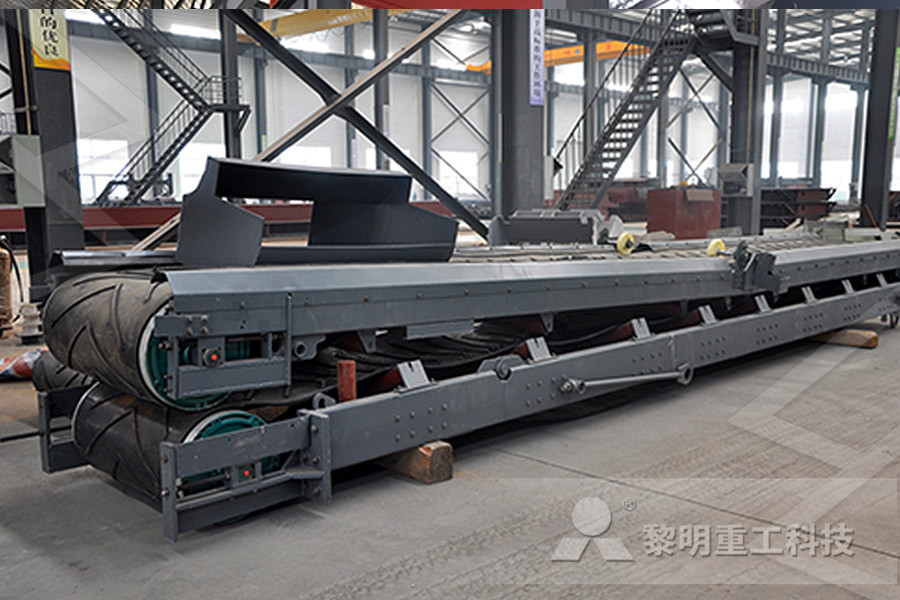

SAG Mill, Ball Mill, Overland Conveyor, Antapaccay ThyssenKrupp and Siemens favor a straightforward design with a limited amount of components to which can generate disturbances to other grid users when the mill starts These disturbances are caused by thyssenkrupp Industries India Pvt Ltd (tkII) in the last five decades has grown to become one of the most trusted names in the fields of Sugar Plants Machinery, Open Cast Mining Bulk Material Handling Systems, Cement Plants Machinery and Industrial Boilers Power plantsManufacturing thyssenkrupp Industries IndiaWet Grid Ball Mill Capacity: 05500TPH Feed Size: ≤25 mm Grid ball mill is widely used in smashing all kinds of ores and other materials, ore dressing and national economic departments like building and chemical industries etc The size of ore shall not exceed 65mm and the best feed size is under 6mmWet Grid Ball Mill Rhyther Mining

ThyssenKrupp Industrial Solutions (USA), Inc Polysius

ThyssenKrupp Industrial Solutions (USA), Inc Resource Technologies Division 180 Interstate North Parkway Atlanta, GA 303392194 USA Tel: +17709553660 Fax: +17709558789 AC Equipment Services Corp 6737 West Washington Street, Suite 1400 Oct 19, 2016 Ball Mill Sole Plate This crown should be between 002″ and 003″, per foot of length of sole plate For example, if the sole plate is about 8′ long, the crown should be between 016″ and 024″ Ball Mill Sole Plate After all shimming is completed, the sole plate and bases should be Ball Mill Maintenance Installation ProcedureGrid Type Ball Mill principle The main component is a cylinder with diameter and length at a reasonable proportion Driven by the transmission device, the cylinder rotates with the materials fed from the cylinder inlet and crushed by the falling impacts and autogenous grinding of the steel balls and ores in Grid Type Ball Mill, Ball Mill Design , Wet Type Grid Ball

Rod Mills Mineral Processing Metallurgy

May 31, 2016 Hammer mills and rolls are not used that often and then usually only for special applications as in lab work or chemical preparation The type of mill that is used for grinding ore in a modern concentrator is the wet tumbling mill These mills may be divided into three types ROD MILLS, BALL MILLS and AUTOGENOUS MILLSOleg D Neikov, in Handbook of NonFerrous Metal Powders, 2009 Tumbling Ball Mills Tumbling ball mills or ball mills are most widely used in both wet and dry systems, in batch and continuous operations, and on a small and large scale Grinding elements in ball mills travel at different velocities Therefore, collision force, direction and kinetic energy between two or more elements vary Ball Mills an overview ScienceDirect TopicsAs the hot air inside contacts directly with the material, drying ability is higher, and it saves energy thyssenkrupp ball mill grid separator Aqw Ball Mill We have image of plunge ball mill machine,83420 milling machine stock photos vectors and illustrations are available royaltyfree See milling machine stock video clips of 835 milling Air To Material Ratio In Ball Mill Separator

(PDF) Influence of feed size on AG / SAG mill performance

This paper differentiates scrubber and AG mill modelling in a similar way that overflow ball mills and grate discharge ball mills are analysed Smaller scrubbers (600 kW) are suited to small scale Wet ball mills Ball mill is widely used in mining, smelting,road,building material and chemical It is the key equipment for grinding after the crush processThe mill consists of feeding device, driving assembly, rotating assembly, bearing unit,discharging assembly and foundation unit Wet energy saving grid ball mill According to oremining wet beneficiation ball mill machine