classifiion of crushers on mode of crushing

2020-06-12T16:06:09+00:00

Types of Crushers 911 Metallurgist

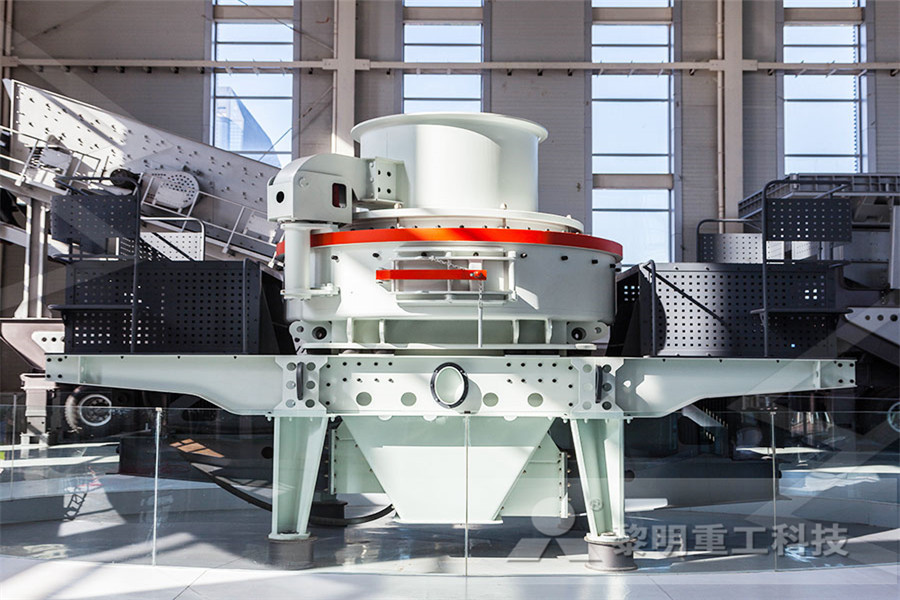

Jun 23, 2015 Crushers may be divided into three general classes, with respect to the manner in which they do their work: Pressure Crushers: This category embraces the several types of gyratory crushers and jaw crushers, as well as the double crushing rolls, with either smooth or corrugated shells Impact Crushers: This division is represented chiefly by the various styles of hammermill; also by the cage Classification Of Crushers On Mode Of Crushing Classification Of Crushers On Mode Of Crushing We are a largescale manufacturer specializing in producing various mining machines including different types of sand and gravel equipment, milling equipment, mineral processing equipment and building materials equipmentClassification Of Crushers On Mode Of Crushingmetal crusher mode Classification of crushers on mode of crushing henan classifi ion of crusher on mode of crushing crushers and mills for crushing and milling samples from about 75mm in circuit or closed circuit with a classifiion screen or hydro cy continuous mode ceramic tile how products are made wall and floor tile used forclassification of crushers on mode of crushing

Crusher an overview ScienceDirect Topics

Cone crushers were originally designed and developed by Symons around 1920 and therefore are often described as Symons cone crushers As the mechanism of crushing in these crushers are similar to gyratory crushers their designs are similar, but in this case the spindle is supported at the bottom of the gyrating cone instead of being suspended as in larger gyratory crushersOptimization of a Final Crushing Stage This method applies to other crushers where a control variable is available The crushers are the last size reduction stage in the value chain Over crushing is common The connection between crusher setting and yield is often unknown The rock cannot be repaired We need to control the crusherCrushing Principles of Mechanical Crushingclassification of crushers on mode of crushing; classification of crushers on mode of crushing Virtual reality Pit Quarry Plant simulation software aids in plant management and bridges the gap between theoretical and actual production capability Inquiry Onlineclassification of crushers on mode of crushing

DESIGN AND ANALYSIS OF A HORIZONTAL SHAFT IMPACT

Crushers are commonly classified by the degree to which they fragment the starting material with primary crushers that do not have much fineness, intermediate crushers having more significant fineness and grinders reducing it to a fine powerA crusher is a machine designed to reduce large rocks into smaller rocks, gravel, sand or rock dust Crushers may be used to reduce the size, or change the form, of waste materials so they can be more easily disposed of or recycled, or to reduce the size of Crusher WikipediaCone crushers are built with a rotating mantle in a concave bowl lined with manganese—this is similar to gyratory crushers, but the crushing chamber in cone crushers is not as steeply angled Cone crushers can accept mediumhard to very hard and abrasive feeds that might be dry or wet, though not sticky (whereas gyratory crushers Types of Rock Crushers Quarry Crushing Equipment Kemper

Crushing in Mineral Processing 911 Metallurgist

Dec 26, 2015 The Crusher throw is defined as the distance in the direction of compression the moving crushing surfaces/plates travel from OSS to CSS Throw = OSS – CSS OSS and CSS will define a crusher’s performance The throw of the crusher mechanism usedBased on the mechanism used crushers are of three types namely Cone crusher,Jaw crusher and Impact crusher Our objective is to design various components of an Impact crusher like drive mechanism, shaft, rotor ,hammers, casing ,feed and discharge mechanism which will be useful in minimizing weight, cost and maximizing the capacityDESIGN AND ANALYSIS OF IMPACT CRUSHERScrushers and cone crushers whereas rod m ills and ball mills, closed circuited with a classifier unit, are generally employed for grinding purposes in a mineral processing plant Crushing is a dry (PDF) SIZE REDUCTION BY CRUSHING METHODS

(PDF) A performance model for impact crushers

Understanding Effects of Crushing Mechanism on Aggregate Morphology Using AIMS energy per unit mass presented hereWe propose a new classification function for impact crushers in to design various components of an Impact crusher like drive mechanism, shaft, rotor, hammers, casing, and discharge mechanism which will be useful in minimizing weight, cost and maximizing the capacity and also do their analysis Impact crushers involve the use of impact rather than pressure to crush DESIGN AND ANALYSIS OF A HORIZONTAL SHAFT IMPACT The Sandvik CH cone crusher can be calibrated to achieve specific results, maximize productivity and minimize wear, but any calculation will be undermined without a solid understanding of what is going in to the crusher Sampling is a vital part of the crushing process, to ensure that you know the size distribution of the feedCone crusher basics in 4 minutes — SRP

How Car Crushers Work HowStuffWorks

Jun 30, 2011 Crushers can be portable or stationary Older machines tend to be stationary once they're set up in a scrap yard, they stay there Today, most crushers are portable They are built mounted to a standardsize truck trailer, and can be towed to various locations, set up, used to crush some things, then moved somewhere elseOct 12, 2015 Crush injury can follow prolonged continuous pressure on muscle tissue Crush injury can lead to crush syndrome Ischaemia reperfusion (when the pressure is released from the crushed limb) is the main mechanism of muscle injury in crush syndrome There is traumatic rhabdomyolysisCrush Syndrome Information about crush injuries Patient Crush Crush All Discussions Screenshots Artwork Broadcasts Videos News Guides Reviews So I noticed a uncensored mode in the settings menu and was kind of wondering if this was just to uncensor words or if this was a version of a nude patch? Info here!Uncensored mode? :: Crush Crush General Discussions

Crushers an overview ScienceDirect Topics

931 Coal Jaw Crusher This is used for crushing and breaking large coal in the first step of coal crushing plant applied most widely in coal crushing industry Jaw crushers are designed for primary crushing of hard rocks without rubbing and with minimum dust Jaw crushers may be utilized for materials such as coal, granite, basalt, river Figure 51 Schematic diagram of a crusher showingg the open and closedside settings 51 Jaw and Gyratory Crushers Jaw and gyratory crushers are used mostly for primary crushing They are characterized by wide gape and narrow discharge and are designed to handle large quantities of material The capacity of the crusher is determined by its sizeTECHNICAL NOTES 5 CRUSHERS Mineral Techfor the cone crushers which are used to crush the rocks China University of Mining And Technology, have Chart1: Work Methodology 42 Proposed Method The crusher that is designed is done in such a way that even a layman can operate it The current crusher uses crank and slotted lever mechanism to crush the materialsDESIGN OF MECHANICAL CRUSHING MACHINE

Crusher Wikipedia

A crusher is a machine designed to reduce large rocks into smaller rocks, gravel, sand or rock dust Crushers may be used to reduce the size, or change the form, of waste materials so they can be more easily disposed of or recycled, or to reduce the size of Cone crushers are commonly used for secondary crushing (although impact crushers are sometimes used), which typically reduces material to about 25 to 10 centimeters (1 to 4 inches) The material (throughs) from the second level of the screen bypasses the secondary crusher because it is sufficiently small for the last crushing stepAP42 Section 11192 Crushed Stone Processing and mechanism usedBased on the mechanism used crushers are of three types namely Cone crusher,Jaw crusher and Impact crusher Our objective is to design various components of an Impact crusher like drive mechanism, shaft, rotor ,hammers, casing ,feed and discharge mechanism which will be useful in minimizing weight, cost and maximizing the capacityDESIGN AND ANALYSIS OF IMPACT CRUSHERS

Crushing in Mineral Processing 911 Metallurgist

Dec 26, 2015 The Crusher throw is defined as the distance in the direction of compression the moving crushing surfaces/plates travel from OSS to CSS Throw = OSS – CSS OSS and CSS will define a crusher’s performance The throw of the crusher is the distance that moving jaw moves in going from OSS to CSS The capacity is a function of size and OSSUnderstanding Effects of Crushing Mechanism on Aggregate Morphology Using AIMS energy per unit mass presented hereWe propose a new classification function for impact crushers in (PDF) A performance model for impact crushersThe Sandvik CH cone crusher can be calibrated to achieve specific results, maximize productivity and minimize wear, but any calculation will be undermined without a solid understanding of what is going in to the crusher Sampling is a vital part of the crushing process, to ensure that you know the size distribution of the feedCone crusher basics in 4 minutes — SRP

DESIGN OF MECHANICAL CRUSHING MACHINE

for the cone crushers which are used to crush the rocks China University of Mining And Technology, have Chart1: Work Methodology 42 Proposed Method The crusher that is designed is done in such a way that even a layman can operate it The current crusher uses crank and slotted lever mechanism to crush the materialsThe reverse form of double crush, aptly named reverse double crush, was later described by Dahlin and Lundborg in 1990 after observing patients with an ulnar nerve entrapment at the wrist later developing a similar proximal injury at the elbow 25 The morphology of the lesion seen in double crush is identical to lesions seen in chronic Peripheral Nerve Trauma: Mechanisms of Injury and RecoveryA machine to crush grain will usually be powered by an electrical motor that provides rotational movement You will not use an electrical motor in your model, but will rather turn the handle of a crank by hand This rotational movement should be changed into a reciprocating movement so that the grain will be crushed, like hitting it with a hammerDesign and make a model of a machine to crush grain

Effects of strain rate on failure mechanisms and energy

Jan 01, 2019 This mode of failure associated with brittle fracturing crushing mode Instantly after the crush proceeds, the top end of the solid starts to fracture and split in small debris Axisymmetric tubes of different geometries: Mode I • Progressive crushing with microfragmentation of the composite materials associated with large amounts of crush energyThe Fomoroid Crusher’s lair has been found and it seeks to escape Victory Condition: The Fomoroid Crusher is taken out of action Any other result is a loss for the player Don’t Let it Escape: After the Fomoroid Crusher ends a Move action within 4 hexes of the escape, choose one friendly fighter Inspire that friendly fighterA CRUSHING TERROR Warhammer CommunityIMPACT CRUSHING Impact crushers may be used as primary, secondary, or tertiary crushers Despite having a somewhat higher operating cost than other crushers, they tend to produce a more uniform particle shape Impact crushers usually will benefit the aggregate better than compression crushers, and they may generate more fines5 Aggregate Production INgov

Femur Shaft Fractures (Broken Thighbone) OrthoInfo AAOS

The long, straight part of the femur (thighbone) is called the femoral shaft When there is a break anywhere along this length of bone, it is called a femoral shaft fracture The femur is the longest and strongest bone in the body, and it takes a great deal of force to break itJul 13, 2017 Skin wounds Classification 1 Soft Tissue Injuries o Trauma that happens to the skin is visually exposed o Categorized as a skin wound o Defined as a break in the continuity of the soft parts of body structures caused by a trauma to these tissues o Mechanical forces include: o Friction, scraping, compression, tearing, cutting, penetratingSkin wounds Classification SlideShare