reheating furnace of rolling grinding mill r

2021-04-17T04:04:49+00:00

Reheating Furnace Reheating Furnace for Steel Rolling Mill

Introduction Reheating furnace for steel rolling mill line is a device (an industrial furnace) that heats a material or a workpiece (generally a metal) to rolling forging temperature in the metallurgical industry Structure and composition According to the distribution of furnace temperature, the furnace is divided into preheating section, 08/07/2019 INSIDE THE REHEATING FURNACE OF A ROLLING MILL YouTube MrCool Garage WS Watch later Share Copy link Info Shopping Tap to unmute If playback doesn't begin shortly, try INSIDE THE REHEATING FURNACE OF A ROLLING MILL YouTube06/04/2017 In steel plants reheating furnaces are used in hot rolling mills to heat the steel stock (Billets, blooms or slabs) to temperatures of around 1200 deg C which is suitable for plastic deformation of steel and hence for rolling in the mill Vikas Yadav Follow Student at University of Pune Reheating Furnace in Rolling Mill Industries 1Reheating Furnace in Rolling Mill Industries SlideShare

Reheating Furnace Division – HOT ROLLING MILL MANUFACTURING

PREET’S Furnace Division is one of India’s most reputed The Division designs and manufactures fuelfired and electric furnaces for reheating and heat treatment applications It was the first furnace company in India to be registered by the Government of India as a furnace manufacturer The client base spans multiple industries, including 13/04/2013 Reheating furnaces are used in hot rolling mills to heat the steel stock (Billets, blooms or slabs) to the rolling temperatures of around 1200 deg C which is suitable for plastic deformation of steel and hence for rolling in the mill The heating process in a reheating furnace is a continuous process where the steel stock is charged at the furnace entrance, heated in Reheating Furnaces and their Types IspatGuru01/06/2017 The reheating furnace heats the charged steel material to the rolling temperature for its hot rolling in the rolling mill Rolling temperature is that temperature which makes the steel charge suitable for the plastic deformation in the rolling process For this, the steel is to have temperatures where its microstructure is in the austenitic rangeHeating of Steel in Reheating Furnace IspatGuru

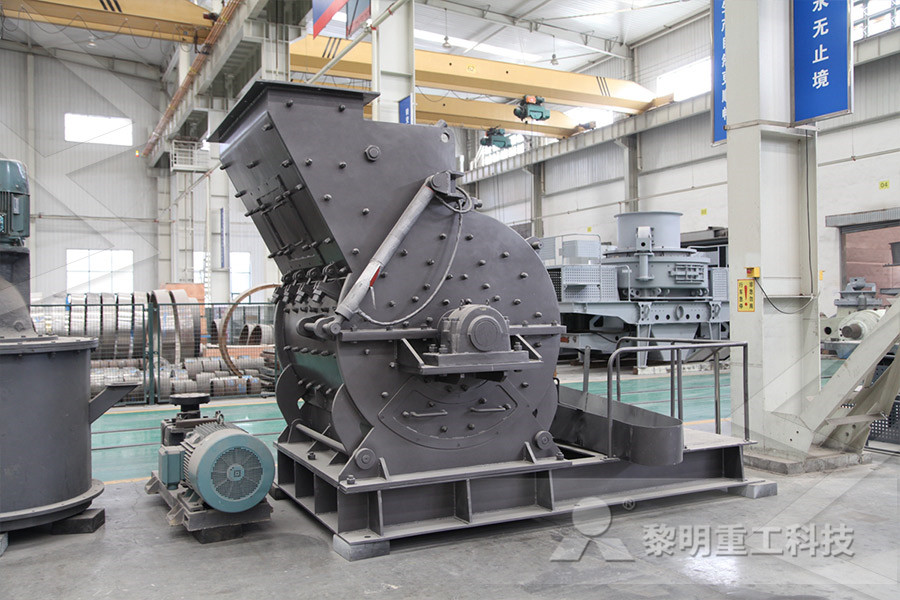

Coal Grinding Mill For Reheating Furnace

Coal Grinding Mill For Reheating Furnace coal pulverizer use reheating furnace in rolling mill coal use in roling mil Roller mills are typically used in coal fired power 1 Grinding rollers in roller mills are subject to considerable wear; pulverizer approximately 25 mm of Bearings for Pulverizers and Vertical Rolling Mills Mining Technology Jul 28, 2016 Rather in the raw or Reheating Furnace Of Rolling Mill How To Automate It the installation of slab reheating furnace No5 in the hot rolling mill The works carried out in the hot rolling mill are expected to allow Siderar to roll all slabs in a single greater thickness of 200 millimeters These works, together with those carried out in the steel shop, would enable Siderar to increase hot reheating furnace of rolling mill gardenstatefr08/07/2019 This video contains a brief knowledge on Furnace Brick, Shoulder Brisk, Heating Flame Direction, Motion of Billets inside a Reheating Furnace, Recuperator, BINSIDE THE REHEATING FURNACE OF A ROLLING MILL YouTube

Roller Hearth Reheating Furnace Hani Tech

13/05/2020 Roller Hearth Reheating furnace is a piece of the important equipment in thin slab continuous casting rolling mill production line It plays a connecting role in function On the one hand, it heats the slab from continuous casting to the tapping temperature required by the rolling process of 1150 (+10) This temperature precision is much higher than the temperature Good quality reheating furnace of rolling mill from reheating furnace of rolling mill manufacturer, Buy reheating furnace of rolling mill online from China Home Products About Us Factory Tour Quality Control Contact Us Request A Quote News Sales Support: English French German Italian Buy reheating furnace of rolling mill, Good quality reheating furnace of rolling mill Manufacturers Directory find 34 reheating furnace of rolling mill from reheating furnace of rolling mill online Wholesalers for reheating furnace of rolling mill Popular reheating

Reheating Furnace Of Rolling Mill

Reheating Furnace Of Rolling Mill Click Here >: Get Latest Price Rolling mill furnace this is the heart of any hot rolling mill where in the charge is heated to rolling temperatureThe charge could be in the form of billets, blooms, slabs or ingotsThe type of furnace could be pusher, walking hearth or walking beam either top fired or top and bottom fired10/03/2021 Heating Furnace What You Need to Know 1 Heating furnace's purpose The heating furnace is to heat the billet to a uniform temperature (austenite structure) suitable for rolling After the temperature increases, the first thing is to improve the plasticity of the steel and reduce the deformation resistance, so that the steel is easy to deformRolling Mill Production Line: Heating Furnace What You The furnace in rolling mill is a device that heats the material or workpiece According to the heat source, there are fuel heating furnace, resistance heating furnace, induction heating furnace, microwave heating furnace, and so on Applications include petroleum, chemical, metallurgy, machinery, heat treatment, surface treatment, building materials, electronics, materials, light The Function and Working Principle of Rolling Mill Heating

A REVIEW ON: EFFICIENT ENERGY OPTIMIZATION IN REHEATING

shop such as slabs, blooms billets are reheated in reheating furnace to a temperature of 1260 oC to 1280 C,using mixed gas loss) takes place and it depends on the variation of the time temperature cycle with rolling rate and mill delays, presence of CO 2, SO 2, moisture and unburnt oxygen etc in the flue gas The aim of this paper is to analyze the possibilities for Pulverizer Mill Plants, Coal Pulverizers Mill Plants Double Zone Reheating Furnace ; latest technology Hammer Mill to crush coal in to fine powder Pulverization in this mill is done by continuous impact of rotating Coal Pulverization Process Of Reheating Furnace Crusher The Benefits of Preet Rebar Rolling Mill Bar Rolling Mill Capacity: 300,000 – 1,000,000 T/Year with multistrand rolling technology (Slitting Rolling Mill Technology) Production upto 1,000,000 t/year: High hourly Production, Reliable and stable Rolling Operation, Reduce stand changing time (Housingless Stands and Roll Pass Design)ReBar Rolling Mill Division – HOT ROLLING MILL

INSIDE THE REHEATING FURNACE OF A ROLLING MILL YouTube

08/07/2019 This video contains a brief knowledge on Furnace Brick, Shoulder Brisk, Heating Flame Direction, Motion of Billets inside a Reheating Furnace, Recuperator, BReheating Furnace For Rolling Mill China Factory, Suppliers, Manufacturers We've got a really efficient group to deal with inquiries from prospects Our purpose is "100% customer fulfillment by our product excellent, price our group service" and enjoy a superb track record amid clientele With many factories, we can easily deliver a wide selection of Reheating Reheating Furnace For Rolling Mill jsyngylyreheating furnace of rolling mill Manufacturers Directory find 34 reheating furnace of rolling mill from reheating furnace of rolling mill online Wholesalers for reheating furnace of rolling mill Popular reheating

China Reheating Furnace For Rolling Mill Manufacturers and

Reheating Furnace For Rolling Mill; Reheating Furnace For Rolling Mill China Factory, Suppliers, Manufacturers To be a result of ours specialty and service consciousness, our enterprise has won an excellent status between buyers all around the globe for Reheating Furnace For Rolling Mill, Continuous Bright Annealing Furnaces, Ring Furnace, forging reheating furnace of rolling millinduction furnace and rolling millroughing stand for rolling millpusher type reheating furnacerubber roller for rice millproject report for rice milldigital readout for bridgeport millgrinding balls for ball mill reheating furnace for rolling mill reheating furnace for In any hot rolling operation the reheating furnace is a critical factor to determine endproduct quality, as well as the total costs of the operation Energy use in a reheating furnace depends on production factors (eg stock, steel type), operational factors (eg scheduling), and design features Based on seven sites, average total primary energy requirement of 12 GJ/tcast Rolling Mills Industrial Efficiency Technology Measures

SAFETY GUIDELINES FOR IRON STEEL SECTOR

material to rolling mill for rolling operation c) Reheating Furnace: To convert chemical energy of fuels into heat energy and heat the material to required temperature efficiently and economically Reheating furnace prepares the material for further hot rolling operation The reheating operation includes Charging, Pushing, heating and discharging/conveying to rolling c) Reheating Furnace: To convert chemical energy of fuels to heat energy and heat the material to required temperature efficiently and economically Reheating furnace prepares the sock material for further hot rolling operation The reheating operation includes Charging, Pushing, heating and discharging/conveying to rolling millSAFETY GUIDELINES FOR IRON STEEL SECTOR MINISTRY OF Reheating furnace: Better control on heating of slabs to achieve optimum rolling temperature • Roughing mill: Precise control of roll gaps enables better stock control in each pass and avoids excess loading on mill rolls and drive systems owing to improper roll gaps Faster and precision gap setting increases mill output •Hot Strip Mill an overview ScienceDirect Topics

ReBar Rolling Mill Division – HOT ROLLING MILL

The Benefits of Preet Rebar Rolling Mill Bar Rolling Mill Capacity: 300,000 – 1,000,000 T/Year with multistrand rolling technology (Slitting Rolling Mill Technology) Production upto 1,000,000 t/year: High hourly Production, Reliable and stable Rolling Operation, Reduce stand changing time (Housingless Stands and Roll Pass Design)