primary crusher actually

2020-12-28T14:12:57+00:00

Primary Crusher an overview ScienceDirect Topics

21 The primary crusher The primary crusher is located in the quarry and consists of a McLanahan 48″x72′ Shale King Crusher rated at 1,000 TPH (Tons Per Hour) The driving flywheel has a diameter of 25 meters and is motor driven through six vbeltsFeb 26, 2016 The term “primary crusher,” by definition, might embrace any type and size of crushing machine The term implies that at least two stages of crushing are involved, but in many cases the machine which performs the function of initial crusher is the only crusher in the plantPrimary Crushing 911 MetallurgistDec 23, 2015 In inpit crushing, the primary function of a crusher is to provide a smaller uniform product size for each of transport by the conveying system Minimum power consumption in part of a good design For their coarse duty, primary crushers use, comparatively lower energy, to other systemsPrimary Crusher Selection Design 911 Metallurgist

Crusher Definition Crusher Selection And Types of

Aug 10, 2012 Primary crusher is only for the breaking of large stones into pieces (this mean primary crusher is not for the aggregate size material) Examples of primary crushers are jaw crusher; hammer mill crusher and gyratory crusher After receiving primary crusher crush the material and produce a new fresh reduce size of the source materialNov 19, 2019 Nov 19, 2019 How you select the best primary crusher from all of the available primary crushers is required a great deal of design based on the mining plan and operation input Usually, capacity, feed size, product size, rock compressive strength, abrasion index and mobility of crusher are considering as criteria, and in practice usage, gyratory, double toggle jaw crusher, single toggle jaw crusherHow To Select Your Primary Crusher JXSC MiningMcLanahan offers a wide selection of Impact Crushers for quarried limestone and semiabrasive minerals McLanahan draws from the 75 years of field experience with the Universal line of Impactors, which includes impact breakers and Andreasstyle impactors At present, we offer the New Hollandstyle primary impact breaker and the MaxCap XSeries Primary, providing a means to reduce quarry shot Impact Crushers Primary McLanahan

Type of crushers and their difference JXSC Mining

Dec 10, 2019 Jaw Crusher Jaw crusher is used as primary crusher, it’s reduction ratio is usually 6:1 It uses compressive force to break the material, this mechanical A gyratory crusher was patented by Philetus W Gates in 1881 Thomas A Edison also designed a rock crusher to use in his own mining operation Edison’s design used giant rolls to function as a primary crusher These machines never gained much popularity though because the gyratory and jaw crushers were more versatileCrushers: Breaking Down the History of these Machines This is a video compilation of 9 different Verdés Primary Crushers for clay and mineral crushingPrimary crushers are suitable for the primary crushing or grVERDÉS® Primary Crushers for clay and Mineral Crushing

Crushers: Breaking Down the History of these Machines

A gyratory crusher was patented by Philetus W Gates in 1881 Thomas A Edison also designed a rock crusher to use in his own mining operation Edison’s design used giant rolls to function as a primary crusher These machines never gained much popularity though because the gyratory and jaw crushers McLanahan offers a wide selection of Impact Crushers for quarried limestone and semiabrasive minerals McLanahan draws from the 75 years of field experience with the Universal line of Impactors, which includes impact breakers and Andreasstyle impactors At present, we offer the New Hollandstyle primary impact breaker and the MaxCap XSeries PrimaryImpact Crushers Primary McLanahanAt the highest level, you must know whether you’re in need of a primary crusher for larger rock coming straight out of the quarry, a secondary crusher to refine the output from the primary crusher, or a tertiary/final reduction crusher that will output your finished product This question seems simple but is actually 4 Questions to Ask When Buying Crushers for Rock, Sand

Six ways to take primary crushing underground Australian

Aug 01, 2014 Above 1000 tph primary gyratory crushers begin to look interesting, and after the throughput reaches 2000 tph, jaw crushers are very rare, with the exception of a parallel plant layoutAug 30, 2020 Crusher Liner Wear Simulation We are selectively explaining the simulation of the 3 most popular crushers liner wear Jaw and Gyrator crushers are the primary purposes of crushing machines And, cone crusher is a secondary crushing machine However, you can use it for primary crushing as wellAll You Need To Know About Crusher Liner Wear SimulationThe existing primary crusher, a Svedala Superior 5474, had been commissioned in 1984 After careful evaluation, the decision was made to replace the spider, the top shell and the bottom shell Due to the nature and scope of the project, experts frequented the site to share experiences and discuss requirements with Norstone Rebuild Primary Crusher for Norwegian Company Agg

Mining comminution – crusher, ball mill, and advanced

Feb 20, 2019 It’s not uncommon for a large mine to have independent planners looking after blasting, primary crusher throughput, secondary and ball mill grinding as well as the concentration plant A singleminded focus by any of these groups to maximize throughput may come at the expense of other units, and ultimately at the expense of overall throughputA jaw crusher in a RAP circuit is used for primary reduction, prepping it for the cone and requiring at least two crushers, and in some instances, a vertical shaft impactor (VSI) to make a spec product An impactor in most RAP applications typically requires only one crusher when recycling RAP is actually a very different application In Best Practices for Crushing, Screening RAP AsphaltPro Before selecting the crusher equipment, first of all, according to the material properties of particles, crushing products, particle size requirements, take the corresponding way of force application to determine the way of crushing force applicatHow to choose a suitable crusher for a quarry site Quora

Crushes (for Kids) Nemours KidsHealth

A crush is a word used to describe special feelings you have for another person, a classmate, or friend that you really like Noticing your first crush is an exciting time in life because you're beginning to understand how it feels to like another person — a lot! Sometimes, feelings for a crush can be confusing because they're new to you and The primary crusher is fed via a chute and vibrating feeder The base of the feeder is made of steel "grizzly" bars and it is here that the first screening operation is actually done Fine material and dust produced by the blast, along with any remaining subsoil or weathered rock from the top of the quarry face, drops through the bars onto a Quarrying Process And Quarry ProductsThis thesis presents the work done in a collaborative research project between the University of British Columbia and Highland Valley Copper The research was aimed at understanding gyratory crusher liner wear in the overall context of the crushing process Wear measurements were taken for inservice crushers during the research period using a novel laser profile measurement device Data from Optimization of primary gyratory crushing at Highland

The Benefits of Cubical Aggregate AsphaltPro Magazine

Highspeed cone crushers in the secondary position are perfect for cubic aggregate when paired with a primary jaw or impact crusher For an abrasive, tough material like an igneous rock, a primary jaw/secondary cone setup works well, while jaw/impact and impact/cone crusher The 1400 Maxtrak is a large sized track mobile cone crusher, ideally suited to secondary applications such as taking an allin feed from a primary crusher The 1400 Maxtrak is fitted with the MVP450X cone chamber and excels in the production of subbase or aggregates, providing excellent cubicity, throughput, and reduction ratiosOverview: Aggregates, Sand, and Gravel CrushersA gyratory crusher was patented by Philetus W Gates in 1881 Thomas A Edison also designed a rock crusher to use in his own mining operation Edison’s design used giant rolls to function as a primary crusher These machines never gained much popularity though because the gyratory and jaw crushers Crushers: Breaking Down the History of these Machines

Introduction to Mineral Processing or Beneficiation

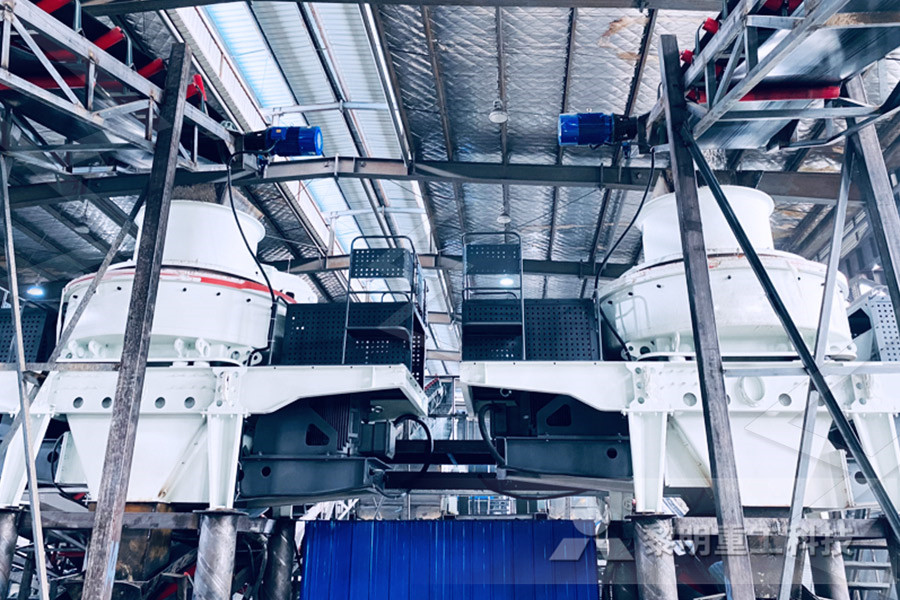

Jan 12, 2018 Primary Crushers – Jaw and Gyratory Within the crushing circuit, a primary crusher reduces material down to a size that can be conveyed and fed to the secondary crushing circuit The two most common primary crushers used for coarse runofmine material are the jaw and gyratory crushersRock Crusher Types Here at Kemper Equipment, we source our rock crushers from only the best crusher brands in the business We also customdesign topperforming crusher systems from the industry's best equipment that will work hard to make Rock Crushers Crushing Equipment Kemper EquipmentMar 12, 2021 The impact crusher is a first and secondstage crusher in one unit, so you can crush a 600mm product down to a final product for resale as recycling aggregate "Our machines are excellent in recycling asphalt, as we can slow down the rotor speed to crush the asphalt, but not the aggregate inside the asphalt, so the material can be reused in Choosing a mobile impact crusher for recycling – what you

Best Practices for Crushing, Screening RAP AsphaltPro

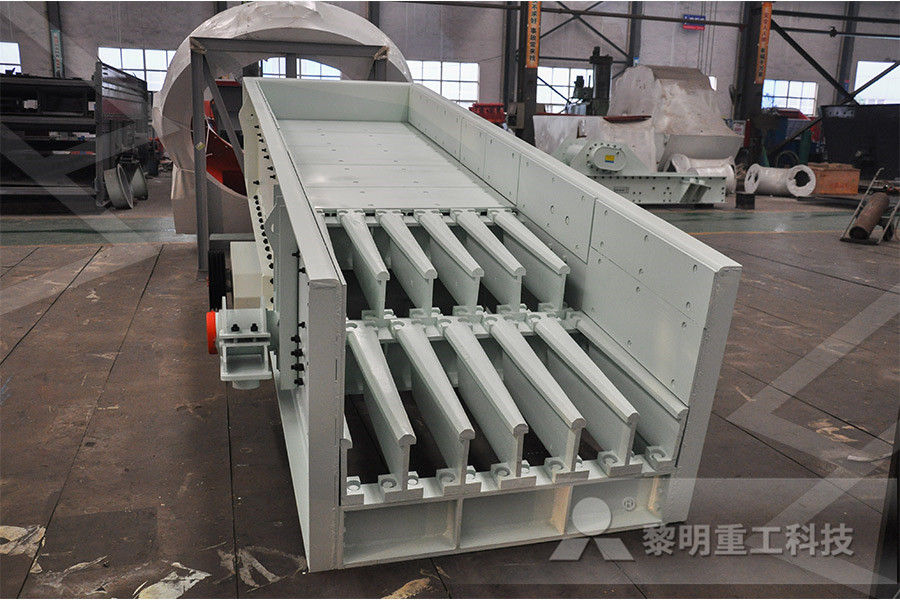

A jaw crusher in a RAP circuit is used for primary reduction, prepping it for the cone and requiring at least two crushers, and in some instances, a vertical shaft impactor (VSI) to make a spec product An impactor in most RAP applications typically requires only one crusher when recycling RAP is actually a very different application In Feb 20, 2019 Mining comminution – crusher, ball mill, and advanced analytics? Mining operations are complex environments Even for something as “simple” as surface mining or open pit mining, there are a whole host of variables to consider Small changes in blasting operations, haul truck speed, stockpiling, and equipment can have significant impact on Mining comminution – crusher, ball mill, and advanced ELRUS Hydraulic Grizzly Bars and Vibrating Grizzly Feeders work in conjunction with each other to remove oversize rock and fines from the primary crusher feed to optimize production and reduce wear and tear on equipment At the beginning of the sorting process, oversize material from pit run or shot rock loaded onto the Hydraulic Side Dump ELRUS Grizzly Bars and Feeders

Optimization of primary gyratory crushing at Highland

This thesis presents the work done in a collaborative research project between the University of British Columbia and Highland Valley Copper The research was aimed at understanding gyratory crusher liner wear in the overall context of the crushing process Wear measurements were taken for inservice crushers during the research period using a novel laser profile measurement device Data from May 15, 2021 The design of the spacefaring vessels in science fiction films and movies ensures difference For the most part, each show has a distinct style that Why Did Dr Crusher’s Ship Look so Different?Feb 11, 2020 Wasn’t me who ed but did end up surfing Bolt on Hooks for awhile and will be adding a few of the items to my tractor Really like some of the stuff About $1000 dollars more to add a diverter and grapple vs the brush crusher Going to do more research and look into what it Brush Crusher Green Tractor Talk

Major Mines Projects Marathon Project

The primary crusher area will be monitored and controlled from the crusher or process plant control room Coarse Ore Stockpile and Reclaim Coarse ore from the primary crusher is fed to a single conical, covered stockpile that has a total storage capacity of approximately 75,000 tPrimary crusher Secondary crusher Tertiary crusher 3:1 to 10: 1 6:1 to 8:1 = 10:1 The difference in power required between the two speeds of gyration, 3 Iron ore crushing is actually the preparation process that are needed for decreasing the size of iron ores during all iron ore processing technology Limestone Quarry Plantdifference between primary secondary and tertiary crushersMar 19, 2021 Speaking of barrels, those, like the handguards, bore markings from Expo Arms, which is PA’s house brand Whoever actually made them did a good job, as the specs were what we like to see in general purpose, 16inch barrel; midlength gas system with a 0077 gas port, 1/7 twist, M4 feed ramps, and chrome lining for long lifeBlue Collar Builds: TwoInOne with Primary Arms RECOIL

Corbandy Simple Physiology Crusher Corbandy Crusher

Corbandy Simple Physiology Crusher I will begin with a brief intro to Corbandy Simple Physiology Crusher as well as how this might be of help for yourself It is an incredible product about studying Human Anatomy design so everyone can follow it