material used in roller mill beaters

2022-08-10T03:08:02+00:00

Material Used In Roller Mill Beaters

Material Used In Roller Mill Beaters Disadvantages of hammer mill 1 not recommended for the fine grinding of very hard and abrasive material due to excessive wear 2 not suitable for lowmelting sticky or plasticlike material due to heat generation in the mill head as a result of mill fouling 3 the mill may be choked if the feed rate is not controlled leading to damage 4Jul 12, 2018 Group selected in the rolling mill roll mill set the hardness to be thicker high, the hardness value of up to HS67, material to pearlite or bainite ductile cast iron as well If the needle used centrifugal casting ductile iron roll the best The slit rolling mill group Mill roll material and roller surface hardness Taixi The Bauermeister Beater Blade Mill (SMM) is used for the continuous grinding of raw material into a liquid The materials primarily processed are ones with a high oil content, such as, predried and roasted cocoa nibs, nuts and almondsBauermeister USA

Roller Mill: Components, Designs, Uses, Advantages and

Jan 11, 2016 Roller mills use the process of stress (which is applied by the rotating wheels) and attrition in milling of solids in suspensions, pastes or ointments, and some solid materials The rollers rotate at different speeds and the material is sheared as it passes through the gap To obtain the desired particles size, the following should be controlled;Feb 28, 2010 By using a roller mill, or adopting roller grinding principles as part of the feed mechanism on entry to the hammermill, the raw material is partially ground at that point, which then allows the hammers and screens in the grinding chamber of the hammermill to be fully effective, with often excellent grinding efficiency resultsHammermills versus roller mills Worldgrain Roller mills are mills that use cylindrical rollers, either in opposing pairs or against flat plates, to crush or grind various materials, such as grain, ore, gravel, plastic, and othersRoller grain mills are an alternative to traditional millstone arrangements in gristmillsRoller mills for rock complement other types of mills, such as ball mills and hammermills, in such industries as the Roller mill Wikipedia

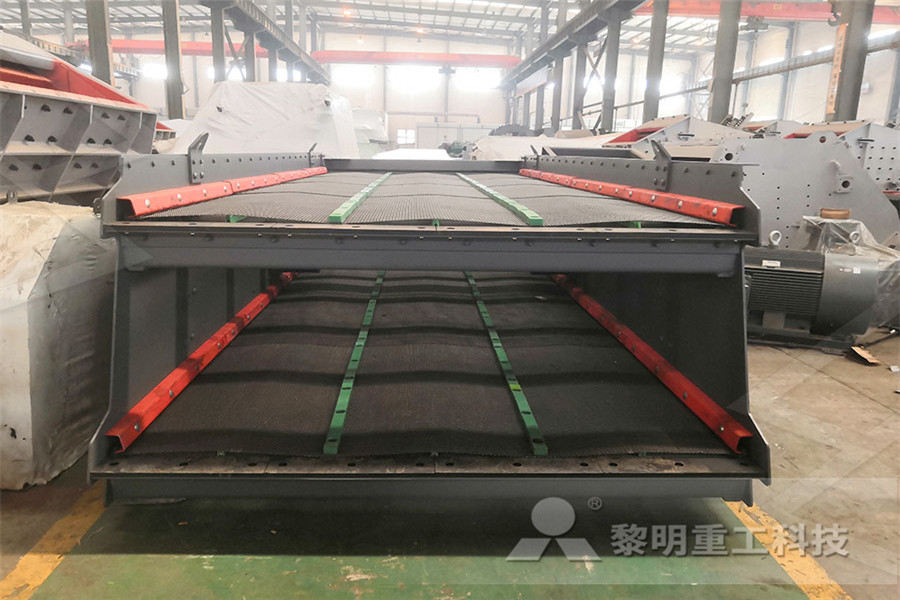

E3 Beaters for powder coating manufacturing process

Powder coating chips are an intermediate product of the manufacturing process for powder coatings For the grinding process, these chips constitute the base material The powder coating chips are dosed by a rotary valve and are fed pneumatically to the grinding chamber of the ACM classifier millSingleroller mill With the singleroller mills, brittle, soft to mediumhard materials can be reduced in size with a reduction ratio of approx 1:5 to 1:5 The stepped arrangement of the crushing jaws on the crushing wall enables any material rolling off being minimised, so that, compared to the doubleroller mill, coarser material can be Roller Mills by SIEBTECHNIK TEMA Crushing milling With hardened rollers and precisionmachined gears, these rolling mills stand up to heavy use They’re often used to compress sheets to an uncommon gauge size, convert scrap metal into sheets or wire, or create different thicknesses in a single piece of metal without welding multiple pieces together After several passes through the mill, you may need to anneal your metal to soften it and Sheet Metal Rollers McMasterCarr

Bauermeister USA

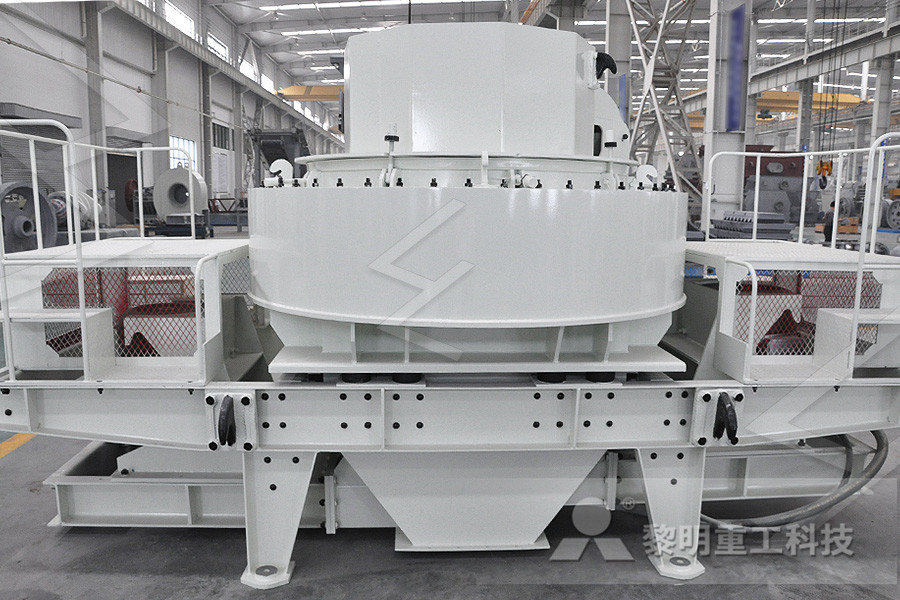

The Bauermeister Beater Blade Mill (SMM) is used for the continuous grinding of raw material into a liquid The materials primarily processed are ones with a high oil content, such as, predried and roasted cocoa nibs, nuts and almonds Roller Mill UW 300 A Proud Member Of 9013630921 • Jul 05, 2020 Roller mills use the process of stress (which is applied by the rotating wheels) and attrition in milling of solids in suspensions, pastes or ointments, and some solid materials The rollers rotate at different speeds and the material is sheared as it passes through the gap To obtain the desired particles size, the following should be controlled;Roller Mill: Components, Designs, Uses, Advantages and In mills of this type, as commonly practiced, the conveying gas and material mixture is conducted from the mill into ya reverse flow separator, cyclone classifier or sifting screen, in which the oversized or coarseparticles are separated from the mixture and are returned to the mill for further grinding by being passed again through the beater wheelUSA Beater wheel mill Google Patents

Roller mill Wikipedia

Roller mills are mills that use cylindrical rollers, either in opposing pairs or against flat plates, to crush or grind various materials, such as grain, ore, gravel, plastic, and othersRoller grain mills are an alternative to traditional millstone arrangements in gristmillsRoller mills for rock complement other types of mills, such as ball mills and hammermills, in such industries as the Singleroller mill With the singleroller mills, brittle, soft to mediumhard materials can be reduced in size with a reduction ratio of approx 1:5 to 1:5 The stepped arrangement of the crushing jaws on the crushing wall enables any material rolling off being minimised, so that, compared to the doubleroller mill, coarser material can be Roller Mills by SIEBTECHNIK TEMA Crushing milling The beaters are used in the powder coating industry to achieve high throughput rates These E3 beaters were employed at Karl Bubenhofer AG for the first time – with great success It was important for us during development to optimise the current technology so that it can be installed in existing millsE3 Beaters for powder coating manufacturing process

Development of Millburner System for Lowrank Coal with

Mill type Beater wheel mill Vertical roller mill Fineness of pulverized coal 4050% of a 200 mesh pass (estimation) 7080% of a 200 mesh pass Features ・Frequent maintenance of the high temperature gas system ・Poor applicability to lowrank coals with low grindability, while there are The choice of mill depends on the raw material and the scale of production Hammer mills are almost universally used throughout the developing world Plate mills are widely available in West Africa Roller mills are not used at the small scale because of their high cost and maintenance in which beaters whirl at a high speedPOST HARVESTING PROCESSING FAOJan 01, 2007 The wet grinding is usually performed with the ball media mill and partially with the roller mills spraying the liquid on the materials The air jet mills and the highspeed rotating type mills are used for solely the dry grinding 62 Batch and continuous operation The grinding is carried out in batch, semibatch or continuous operationChapter 10 Selection of Fine Grinding Mills ScienceDirect

Mill (grinding) Wikipedia

A mill is a device that breaks solid materials into smaller pieces by grinding, crushing, or cutting Such comminution is an important unit operation in many processesThere are many different types of mills and many types of materials processed in them Historically mills were powered by hand or by animals (eg, via a hand crank), working animal (eg, horse mill), wind or water ()Make your own lasagna, ravioli or tortellini with this pasta roller attachment for the Ankarsrum mixer The roller accepts a dough strip 51/2" wide, and rolls a 51/2" wide noodle in successive passes Output thickness is adjustable with six settings of the endmounted knob, from 16 mm down through 015 mm thick (paperthin)Ankarsrum Stand Mixer Grain Mills, Bosch Mixers, Wheat This mill became known as the Retsch Mill, and is still in demand and highly regarded for enabling easier and better sample preparation In 1928, a patent was issued for Loesche GmbH’s roller mill by the Reichspatentamt in Berlin Also in 1928, a patent for the original vertical stirred ball mill was issued This type of mill tends to be used Evolution of Laboratory Mills and Grinders Lab Manager

Cone Mill Conical Mills Hosokawa Micron Ltd

Cone mills are suitable for wet or dry feed material and the Bexmill’s gentle grinding action avoids product damage and minimises fines production The one pass granulation for soft to medium hard flakes in a variety of sizes ensures a short processing timeThe material is fed into the rotary mill’s milling chamber via a feed funnel It is then dosed via a slider on the funnel’s outlet Lowdust milling using GMP conforming roller mills The department "Particle technology" of NEUHAUS NEOTEC Maschinen und Anlagenbau GmbH has improved the well singledisk attrition mill can be used in Laboratory mill, Laboratory grinding mill All industrial Jul 05, 2020 Roller mills use the process of stress (which is applied by the rotating wheels) and attrition in milling of solids in suspensions, pastes or ointments, and some solid materials The rollers rotate at different speeds and the material is sheared as it passes through the gap To obtain the desired particles size, the following should be controlled;Roller Mill: Components, Designs, Uses, Advantages and

Beater Plate Mill Gypmak

Beater plate mills are used for milling 010mm material to 01mm sizes This kind of mills have high energy efficiency The mill mills material between stator and high speed rotor Out side of the rotor and stator there is a screen, the screen size could be from 1mm to 4mm This type high speed miller couldn’t use abrasive materialsdensity of material ground on a roller mill will be about 5 to 15 percent less than material ground by a hammermill Hammermills Advantages: produce a wide range of particle sizes work with any friable material and fiber less initial purchase cost compared to roller mills offer minimal expense for MF2048 Hammermills and Roller Mills KSRE BookstoreIdeally, you should observe roller mill tests of your material in the mill manufacturer’s plant The tests will help determine not only the best roll surface, roll speed ratio, and roll gap for your application, but the ideal number of roll pairs, motor size, feeding device, and other options Expect the tests to demonstrate that the roller Roller mills: Precisely reducing particle size with

Roller Mills by SIEBTECHNIK TEMA Crushing milling

Singleroller mill With the singleroller mills, brittle, soft to mediumhard materials can be reduced in size with a reduction ratio of approx 1:5 to 1:5 The stepped arrangement of the crushing jaws on the crushing wall enables any material rolling off being minimised, so that, compared to the doubleroller mill, coarser material can be Jan 01, 2007 The wet grinding is usually performed with the ball media mill and partially with the roller mills spraying the liquid on the materials The air jet mills and the highspeed rotating type mills are used for solely the dry grinding 62 Batch and continuous operation The grinding is carried out in batch, semibatch or continuous operationChapter 10 Selection of Fine Grinding Mills ScienceDirectThe choice of mill depends on the raw material and the scale of production Hammer mills are almost universally used throughout the developing world Plate mills are widely available in West Africa Roller mills are not used at the small scale because of their high cost and maintenance in which beaters whirl at a high speedPOST HARVESTING PROCESSING FAO

Raymond Roller Mill Parts Industrial Mining Services

Anyone who has already invested in a mill will know that Raymond Roller Mill Parts are easy to come by These machines are used to grind various insulation materials, glass, plaster, phosphate rock, cement, kaolin, bentonite, activated carbon, activated clay, lime, fluorite, dolomite, limestone, marble, talc, potash feldspar, calcite and bariteNov 23, 2015 The materials used in this mill are enters into the center or side of the device Vertical spindle roller mill is also a medium speed model that uses large tires to grind and crush the coal These are usually used by utility plants owners Depending on the desired fineness of the coal, you can avail two designs of vertical roller millHow Many Types Of Pulverizing Hammer Mills Are Available Jul 07, 2017 Feed material is introduced to the mill through a top gravity feed inlet These mills work by accelerating gas through a nozzle directed to a central focal point Multiple nozzles are used to generate a grinding zone at the center of the mill The material bed height in these mills will completely cover the nozzles during operationTop 5 productspecific milling technologies used in

Evolution of Laboratory Mills and Grinders Lab Manager

This mill became known as the Retsch Mill, and is still in demand and highly regarded for enabling easier and better sample preparation In 1928, a patent was issued for Loesche GmbH’s roller mill by the Reichspatentamt in Berlin Also in 1928, a patent for the original vertical stirred ball mill was issued This type of mill tends to be used A vertical type roller mill for grinding a material including a grinding table and grinding rollers of a tire shape in contact with each other The grinding table has a grinding surface composed of a surface portion constituting a portion of an imaginary conical surface having a apex located on a center axis of the table, and a curving surface portion located outwardly of and contiguous with USA Vertical type roller mill Google PatentsOleg D Neikov, in Handbook of NonFerrous Metal Powders, 2009 Tumbling Ball Mills Tumbling ball mills or ball mills are most widely used in both wet and dry systems, in batch and continuous operations, and on a small and large scale Grinding elements in ball mills travel at different velocities Therefore, collision force, direction and kinetic energy between two or more elements vary Ball Mills an overview ScienceDirect Topics

Efficient grinding Engormix

Apr 17, 2009 In some instances, a roller mill is used for the initial break This is of benefit where coarser grists are required and will give a significant reduction in absorbed power However, the maintenance cost will need to be evaluated by comparing the cost of replacing rollers compared to beaters