Vsi Crusher Rotor Shaft Design

2021-03-04T12:03:55+00:00

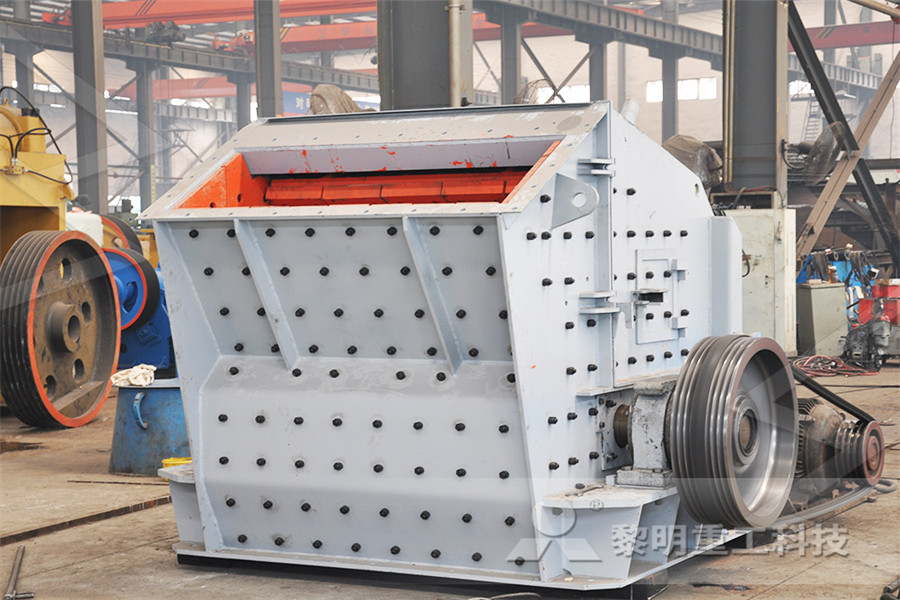

DESIGN AND ANALYSIS OF A HORIZONTAL SHAFT IMPACT

An impact crusher can be further classified as Horizontal impact crusher (HSI) and vertical shaft impact crusher (VSI) based on the type of arrangement of the impact rotor and shaft Horizontal shaft impact crusher These break rock by impacting the rock with hammers/blow bars that are fixed upon the outer edge of a spinning rotorVSI and GS series crushers are characterized by a unique closedrotor design providing a higher reduction ratio with lower wear cost The GS series crusher’s bearing seat uses a thin oil lubrication system Its highest rotor speed is clocked at 82m/s, greatly improving the capacity of the equipment and processing efficiencyVertical Shaft Impact Crusher AF Minerals EquipmentDesign to represent the crusher and rotor geometries in the system The modelled VSI is based on measurements from a Barmac 5100SE VSI crusher taken from a mobile crushing plant located in a quarry in Gävle at the time Eight different rotor designs were created in a systematic way using a Design of Experiments approachModeling and Optimization of a Vertical Shaft Impactor for

Vertical Shaft Impact Crushers MEKA Crushing Screening

VERTICAL SHAFT IMPACT CRUSHER Vertical Shaft Impact (VSI) crushers are designed to be used in secondary, tertiary or quaternary stage crushing The crushers are suitable for a wide range of applications including the production of high quality manufactured sand, well formed aggregates and industrial mineralsThey can crush the hard and abrasive material with low operation costs because of the crushing chamber design with rockonrock system Also the product taken from VSI crushers have cubical shape and more fine So the products of VSI crushers are very good for concrete and asphalt aggregate Special rotor design with high reduction ratiovertical shaft impact crushers Maden Crushing ScreeningDesign to represent the crusher and rotor geometries in the system The modelled VSI is based on measurements from a Barmac 5100SE VSI crusher taken from a mobile crushing plant located in a quarry in Gävle at the time Eight different rotor designs were created in a systematic way using a Design of Experiments approachModeling and Optimization of a Vertical Shaft Impactor for

Vertical Shaft Impact Crusher AF Minerals Equipment

Vertical shaft impact (VSI) crusher is widely used for quaternary, tertiary, and secondary applications of crushing rock, cement clinker, quartzite, and concrete aggregate and especially for the sand making and road paving VSI Crusher Basic Concepts VSI and GS series crushers feature a unique combination of rotor design, wear material, and Crushers can also be used for shaping or removal of soft stone from aggregate Advanced alternatives with open table designs, multiport rotor and larger bearings than many other VSI crushers are the main reasons for our crushers to provide high value solutions and deliver high performance We provide static, wheel mounted VSI plants and Vertical Shaft Impact Crushers MEKA Crushing Screening May 02, 2019 Vertical Shaft Impact (VSI) crushers are designed to be used in secondary, tertiary or quarternary stage crushing The crushers are suitable for a wide range of applications including the production of high quality manufactured sand, well formed aggregates and industrial minerals Crushers can also be used for shaping or removal of soft stone fromVERTICAL SHAFT IMPACT CRUSHERS mekaglobal

Canica VSI VERTICAL SHAFT IMPACT CRUSHERS

the ® Canica VSI crusher selected for your application is the appropriate size and configuration to meet your needs A full size vertical shaft impact crusher duplicates each of the models in the ® Canica family of crushersVertical Shaft Impact (VSI) Crushers VSI crushers are final crushing machines that can work with all type of material They can not be used as secondary crusher since their maximum feed size is not big enough But they are ideal machines for final productvertical shaft impact crushers Maden Crushing ScreeningThe fi rst crusher was a "basic" VSI in concept We learned a great deal about manufacturing and applications since our fi rst crusher was built in 1967, but that fi rst machine is still running in a mine in New Mexico CEMCO continued to build the TurboTM Vertical shaft impact crusher and entered into an agreement with WCAThe History of the VSI Crusher cemcoturbo

CRUSHES PERFECT PRODUCT SQUEEZES YOUR COSTS

A unique, patented rotor design and rockonrock crushing ensure a more consistent product with minimum equipment wear This clever, simple design with fewer parts gives you higher tonnage and greater reliability using less power than any other VSI crusher BOOST YOUR OUTPUT LOWER YOUR COST Sandvik VSI crushers include a patented, 3port rotor that the impact crusher used have a wide operating speed range to accommodate a broad spectrum of material types and feed gradings REMco vertical shaft impact crushers have the broadest operating range of all VSI crushers Please refer to the rotor velocity scale chart For material reduction,RockMax SandMax VSI CrushersAUSPACTOR™ VERTICAL SHAFT IMPACT CRUSHERS HE Parts manufacture and supply the Auspactor™ Range of VSI crushers to global markets The innovative design of the Auspactor™ VSI is based on years of experience and field trials It provides easier and fewer tip and part changes resulting in lower running costsAuspactor™ VSI HE Parts International

Horizontal Vertical shaft Impact Crushers Moore Watson Ltd

VSI Series Vertical shaft Impact Crusher The VSI crusher is a high speed vertical rotor crusher designed to process high specification cubical or fine sand material at a maximum capacity by centrifugal force either against a high wear resistant breaker plate or a bed of rock in the upper chamber on the outer frame of the crusherDESIGN AND ANALYSIS OF A HORIZONTAL SHAFT IMPACT An impact crusher can be further classified as Horizontal impact crusher (HSI) and vertical shaft impact crusher (VSI) based on the type of arrangement of the impact rotor and shaft Horizontal shaft impact crusher These break rock by impacting the rock with hammers/blow bars that are fixed upon the outer edge of a spinning rotorhow to design rotor for vsi crusherThe advanced SINGH Vertical Shaft Impactor or VSI is a superior combination of Rotor design wear material resulting in high efficiency improved crushing performance SINGH Vertical shaft Impact Crushers or VSIs are top notch product with a unique ability to operate in diverse crushing operations for construction, mining industrial Vertical Shaft Impactor (VSI Singh Crushers

Barmac® B Series™ impact crushers Outotec

Barmac® crushers accept fines in the feed and allow user to finetune crusher’s performance by changing the rotor speed or cascade ratio The primary path for feed material is through the rotor where it can be accelerated up to 80 m/s (262 ft/s) before being discharged into the crushing chamberDesign to represent the crusher and rotor geometries in the system The modelled VSI is based on measurements from a Barmac 5100SE VSI crusher taken from a mobile crushing plant located in a quarry in Gävle at the time Eight different rotor designs were created in a systematic way using a Design of Experiments approachModeling and Optimization of a Vertical Shaft Impactor for May 02, 2019 Vertical Shaft Impact (VSI) crushers are designed to be used in secondary, tertiary or quarternary stage crushing The crushers are suitable for a wide range of applications including the production of high quality manufactured sand, well formed aggregates and industrial minerals Crushers can also be used for shaping or removal of soft stone fromVERTICAL SHAFT IMPACT CRUSHERS mekaglobal

vertical shaft impact crushers Maden Crushing Screening

Vertical Shaft Impact (VSI) Crushers VSI crushers are final crushing machines that can work with all type of material They can not be used as secondary crusher since their maximum feed size is not big enough But they are ideal machines for final productThis 40 mm from Jaw crusher can be recrushed in our VSI Crusher and reduced to 20 mm cubical metal and remaing below 12 mm can be fed to Rotopactor for converting in sand The Jaw Crushers are generally used for crushing stone to make metal for concreting work The capacity of the jaw crushers is the factor of RPM and the size of the crusherVSI Crusher Artificial SandA unique, patented rotor design and rockonrock crushing ensure a more consistent product with minimum equipment wear This clever, simple design with fewer parts gives you higher tonnage and greater reliability using less power than any other VSI crusher BOOST YOUR OUTPUT LOWER YOUR COST Sandvik VSI crushers include a patented, 3port rotor CRUSHES PERFECT PRODUCT SQUEEZES YOUR COSTS

RockMax SandMax VSI Crushers

that the impact crusher used have a wide operating speed range to accommodate a broad spectrum of material types and feed gradings REMco vertical shaft impact crushers have the broadest operating range of all VSI crushers Please refer to the rotor velocity scale chart For material reduction,VSI (Vertical Shaft Impactor) great flexibility – easy operation Vertical Shaft Impactors are tertiary crushers for the production of highgrade chippings or crushed sand from hard rock such as basalt, granite, diorite, andesite and gravel 4 port and 5 port rotor design for 100 to 300 TPH plants respectively induces higher volume of VSI (Vertical Shaft Impactor) thyssenkrupp Industries IndiaAUSPACTOR™ VERTICAL SHAFT IMPACT CRUSHERS HE Parts manufacture and supply the Auspactor™ Range of VSI crushers to global markets The innovative design of the Auspactor™ VSI is based on years of experience and field trials It provides easier and fewer tip and part changes resulting in lower running costsAuspactor™ VSI HE Parts International

USDS1 Vertical shaft impact crusher rotor Google

USDS1 US29/609,803 US3F USDS US D S1 USD S1 US DS1 US 3 F US3 F US 3F US D S USD S US DS Authority US United States Prior art keywords vertical shaft impact crusher shaft impact crusher rotor rotor Prior art date Legal status (The legal status is an assumption Vertical Shaft Impact Crusher Nesans Mining and Nesans CF Series Vertical Shaft Impact Crusher are high impact force tertiary stage high output ratio crushers uniquely designed to achieve the required product gradation for the production of msand With dynamically balanced rotor design and robust rotor tips CF Series Vertical Shaft Impact Crusher can save a huge on your maintenance costsvertical shaft impact crusher designEPB1 EP9A EPA EPB1 EP B1 EP B1 EP B1 EP A EP A EP A EP B1 EP B1 EP B1 Authority EP European Patent Office Prior art keywords wear groove rotor wear tip tip holder Prior art date Legal status (The legal status is an assumption and is not a legal conclusionEPB1 Wear tip holder for VSI crusher, and method

Barmac® B Series™ impact crushers Outotec

Barmac® crushers accept fines in the feed and allow user to finetune crusher’s performance by changing the rotor speed or cascade ratio The primary path for feed material is through the rotor where it can be accelerated up to 80 m/s (262 ft/s) before being discharged into the crushing chamberCHPL series verticalshaft impact crusher is the perfect combination of precise manufacturing and excellent design The perfect integration between unique rotor design and effective, precise control bypass feeding system not only greatly enhances production capacity and product quality but also lowers production cost and wear parts consumptionVertical Shaft Impact Crusher Tertiary Crusher SINOMACH5 or 6 shoe table/rotor 1” Feed Size Applications Low Range • 50% to 80% of maximum speed • 4 shoe table/rotor • Tough feed material (basalt, gravel) •1000 Crusher chokefed High Range • 30M80% to 100% of maximum speed • 5 shoe table/rotor • Friable feed material (limestone, dolomite) • Crusher 85% or less of choke feed rate Canica Vertical Shaft Impactors