pelletisation of hematite iron ore fined

2021-06-08T13:06:10+00:00

Gratekiln pelletization of Indian hematite fines and its

DQ Zhu et al, Gratekiln pelletization of Indian hematite fines and its industrial practice 475 riments The bulk density of the iron ore was then measured by using a 700 cm3 graduated flask Nov 26, 2014 Studies of green pellets and induration of magnetite and high grade hematite iron ore fines with low alumina have been carried out in different parts of the world But the results of these studies cannot be directly interpreted to iron ores with higher amount of alumina (Al2O3) due to the difference in chemistry and mineralogyIron Ore Pellets and Pelletization Process – IspatGurustudy the reducibility behaviour of hematite iron ore pellets by altering the coke composition and moisture content Iron ore fines were taken, carefully weighed and used to prepare the pellets 100gm of Iron ore fines were taken, with 05% Bentonite (as Binder), 10% water and coke were added proportionately for each runWASTE MANAGEMENT BY PELLETIZATION OF IRON ORES

Gratekiln pelletization of Indian hematite fines and its

May 04, 2017 Indian hematite fines normally have a high iron grade and minor impurities; they are usually used as sinter fines for feeding into a blast furnace In this work, the grindability properties of two kinds of Indian hematite fines and the roasting behaviors and induration characteristics of pellets made from these fines were revealed through The waste low grade manganiferous iron ore fine from southern part of India was studied for recovery of iron values The chemical assay of the sample is 5236% Fe, 475% Mn, 85% SiO 2 and 282% (PDF) Gratekiln pelletization of Indian hematite fines May 04, 2017 Indian hematite fines normally have a high iron grade and minor impurities; they are usually used as sinter fines for feeding into a blast furnace In this work, the grindability properties of two kinds of Indian hematite fines and the roasting behaviors and induration characteristics of pellets made from these fines were revealed through Gratekiln pelletization of Indian hematite fines and its

WASTE MANAGEMENT BY PELLETIZATION OF IRON ORES

study the reducibility behaviour of hematite iron ore pellets by altering the coke composition and moisture content Iron ore fines were taken, carefully weighed and used to prepare the pellets 100gm of Iron ore fines were taken, with 05% Bentonite (as Binder), 10% water and coke were added proportionately for each runProcess For The Pelletization of Iron Ore Fines pelletizing discs with a size of 7500 mm in diameter and feeding capacities up to 150 t/h Iron ore pellet feed fines (PFF) The iron ore pelletizing process is Iron Ore Processing ,Crushing Screening,Grinding,Beneficiation Process For The Pelletization of Iron Ore FinesIron Ore Pellets are formed from beneficiated or run of mine iron fines The iron is usually ground to a very fine level and mixed with limestone or dolomite as a fluxing agent and bentonite or organic binders as a binding agent If the ore is a Hematite ore, coke or anthracite coal can be added to the mix to work as an internal fuel to help Iron ore pelletizing Outotec

Usage of HighLOI Iron Ore Fines in Pellet Making

Jun 08, 2019 Loss on ignition (LOI) in the mineral represents the chemically bonded water which can be removed at high temperatures only High LOI in iron ore fines has an adverse affect during pellet induration process HighLOI iron ore fines are required for detailed laboratory pelletization studies and are used in pellet making The received iron ore is martite–goethitic and hematite–goethitic form LOW GRADE IRON ORE FINES JUDICIOUSLY 9 Pelletisation is a process of agglomeration of super fine mining of hematite ore which could not be directly used in the iron making process NEED FOR PELLETISATION •Pelletisation process is to make use of Blue dust and ultra fine concentrate generated in the Iron ore beneficiation plantsPELLETISATION Metal Bulletinpelletization of iron ore fines and the influence of particle size on the green pellet properties 2 2 Materials and Methodology 21 Sampling and Characterization Approximately 50 kg of iron ore fines was collected and after sampling was carried out, particle size analysis was done Iron ore sample belongs to the Gua mines, locatedTHE EFFECT OF PARTICLE SIZE ON GREEN PELLET PROPERTIES

pelletisation of iron ore fines: Latest News Videos

Jun 15, 2014 NMDC hikes iron ore price for the second time in November to Rs 4000 per tonne Staterun iron ore producer NMDC Ltd has hiked prices of lump ore for the second time this month by Rs 400 per tonne and that of fines by around Rs 300 per tonne 17 Nov, 2020, 0754 PM ISTHigh grade iron ore less than 10% of the total reserves ROM iron ore with Fe less than 58 – 60% discarded as waste After beneficiation iron ore availability can improve by about 50% Steel community and the country demand technological solutions for utilising low grade ores The technology task that would be imperative: 1SINTERING AND PELLETISATION OF INDIAN IRON ORESIron ore pellet is a kind of agglomerated fines which has better tumbling index when compared with the iron ore and it can be used as a substitute for the iron ore lumps both in the BF and for DRI production Pellets have good reducibility since they have high porosity (25 % to 30 %) Normally pellets are reduced considerably faster than sinterIron Ore Beneficiation And Pelletization

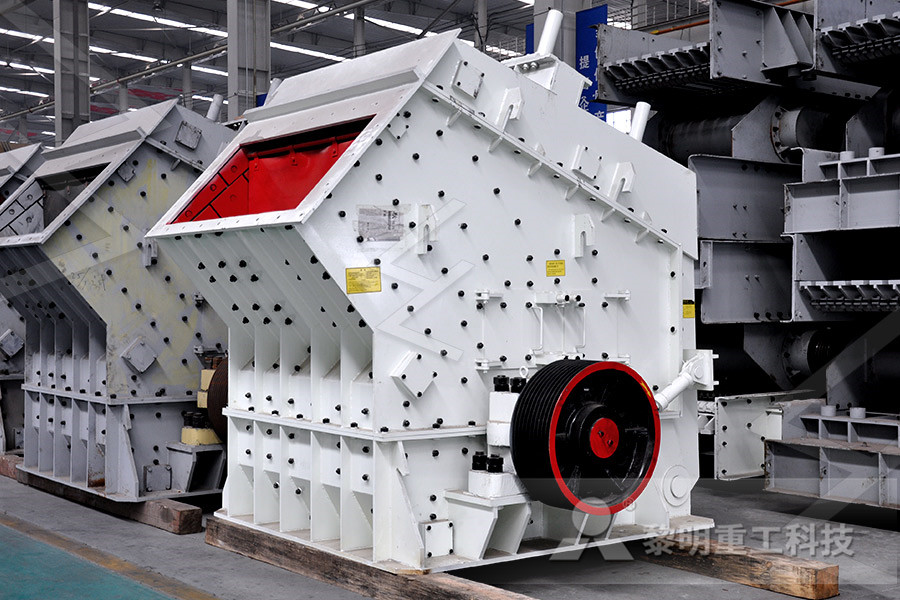

hematite hammer crusher

Pelletisation Of Hematite Iron Ore Fined Society Crushing The various advantages of iron ore pellets are given below Iron ore pellet is a kind of agglomerated fines which has better tumbling index when compared with the iron ore and it can be used as a substitute for the iron ore lumps both in the BF and for DRI production Pellets Day by day highgrade iron ores are fast depleted fines and lowgrade iron ores, which are not utilised earlier, now they can be utilised by up gradation Upgraded concentrates can be used as charge materials for pelletization The present scenario of iron ore reserves stated that out of total 2853 BT [1788 BT Hematite 1064 BT –Improved Reduction Kinetics of Low Grade Iron Ore Pellet RECYCLING OF HEMATITE FINE WASTE BY PELLETISATION Anișoara CIOCAN, Beatrice TUDOR “Dunarea de Jos” University of Galati email: ABSTRACT A large volume of byproducts and residues is generated during iron and steel production Much of these represents valuable materials and can be recovered andRECYCLING OF HEMATITE FINE WASTE BY PELLETISATION

WASTE MANAGEMENT BY PELLETIZATION OF IRON ORES

study the reducibility behaviour of hematite iron ore pellets by altering the coke composition and moisture content Iron ore fines were taken, carefully weighed and used to prepare the pellets 100gm of Iron ore fines were taken, with 05% Bentonite (as Binder), 10% water and coke were added proportionately for each runRECYCLING OF HEMATITE FINE WASTE BY PELLETISATION Anișoara CIOCAN, Beatrice TUDOR “Dunarea de Jos” University of Galati email: ABSTRACT A large volume of byproducts and residues is generated during iron and steel production Much of these represents valuable materials and can be recovered andRECYCLING OF HEMATITE FINE WASTE BY PELLETISATIONIron Ore Pellets are formed from beneficiated or run of mine iron fines The iron is usually ground to a very fine level and mixed with limestone or dolomite as a fluxing agent and bentonite or organic binders as a binding agent If the ore is a Hematite ore, coke or anthracite coal can be added to the mix to work as an internal fuel to help Iron ore pelletizing Outotec

PELLETISATION Metal Bulletin

LOW GRADE IRON ORE FINES JUDICIOUSLY 9 Pelletisation is a process of agglomeration of super fine mining of hematite ore which could not be directly used in the iron making process NEED FOR PELLETISATION •Pelletisation process is to make use of Blue dust and ultra fine concentrate generated in the Iron ore beneficiation plantsJun 15, 2014 NMDC hikes iron ore price for the second time in November to Rs 4000 per tonne Staterun iron ore producer NMDC Ltd has hiked prices of lump ore for the second time this month by Rs 400 per tonne and that of fines by around Rs 300 per tonne 17 Nov, 2020, 0754 PM ISTpelletisation of iron ore fines: Latest News Videos Jan 01, 2015 151 Introduction Iron ore lump, sinter, and pellets comprise the main burden of modern blast furnaces However, sinter and pellets are now the dominant blast furnace burden, because the natural lump supply has declined dramatically due to depletion of the world's highgrade competent iron ore Iron ore pelletization ScienceDirect

Pelletization of iron ore fines with parameter

Iron and Steel industry is considered the backbone of industrial development The mining of iron ore has a prime importance among all the minerals mined in our country1,2 In recent years, Government of India (GoI) has stipulated a rule to use iron ore up to 45% Fe not to dump fines and slimes as waste, so to conserve the limited reservesPelletisation Of Hematite Iron Ore Fined Society Crushing The various advantages of iron ore pellets are given below Iron ore pellet is a kind of agglomerated fines which has better tumbling index when compared with the iron ore and it can be used as a substitute for the iron ore lumps both in the BF and for DRI production Pellets hematite hammer crusherThe rich iron ore deposits are available in the OMC, ORISSA area The source of supply for the plant would be from one or more of the mines As per the Survey conducted by the Indian Bureau of Mines (IBM) in April, 1995, India had 10,052 million tones of Recoverable reserves of Hematite and 3,408 Million Tones of MagnetitePELLETISATION PLANT, Chemical,Physical Metallurgical

SINTERING AND PELLETISATION OF INDIAN IRON ORES

High grade iron ore less than 10% of the total reserves ROM iron ore with Fe less than 58 – 60% discarded as waste After beneficiation iron ore availability can improve by about 50% Steel community and the country demand technological solutions for utilising low grade ores The technology task that would be imperative: 1The Noamundi iron ore fines were ground in a ball mill for 18 minutes to obtain the Blaine fineness of 1870 cm2/g 23 Pelletization process Raw materials such as iron ore, coke, jhama coal, BF flue dust, bentonite (binder) and limestone (flux) were ground into fines size of 100 μm by a ball mill for preparation of pelletsINFLUENCES OF CARBONACEOUS MATERIALS ON THE Hematite Ore, All India 5,982,042 2,111,504 9,788,551 17,882,098 Magnetite Ore, Pelletisation with Beneficiation will increase the feeding to Steel Plants by 15 •Fluctuating prices of iron ore fines and pellets in world market can seriously affect costefficientROLE OF IRON ORE PELLETS TO ACHIEVE TARGET OF

Development on Iron Ore Pelletization Using Calcined

size fraction of iron ore fines prepared for pelletization is shown in Table 1 Chemical analysis of iron ore and fluxes including bentonite are shown in Tables 2 and 3, respectively The used coke fines of –0149 mm size, contains 85% fix C, 13% ash, 1% moisture and 1% VM The iron ore fines has been mixed with bentonite, cokePellets are produced from magnetite concentrates, hematite concentrates, natural ore fines, artificial magnetites and pyrite cinders Binder plays an important role in the success of pelletizing process Of many binders, bentonite has proven to be the most effective one owing to its high water adsorption capacity and dry film strength Use of Boron Compounds as Binders in Iron Ore Pelletization