grinding is the required process when size reduction of below 5 20 mm is needed

2023-04-29T12:04:45+00:00

(PDF) SIZE REDUCTION BY GRINDING METHODS

Mar 04, 2017 In the mining industry, dry grinding plants are primarily used when the downstream preparation process requires dry material, or in order to sav e valuable Grinding is the required process when size reduction of below 520 mm is neededGrinding is a powdering or pulverizing process of many kinds of minerals Ore Beneficiation crushing equipments for rocks and construction waste, and expands the conception of primary and secondary crushing operationgrinding and pulverization of the crushed oreSize reduction by crushing has a size limitation for the final products If we require further reduction, say below 520 mm, we have to use the processes of grindingSIZE REDUCTION BY GRINDING METHODS By

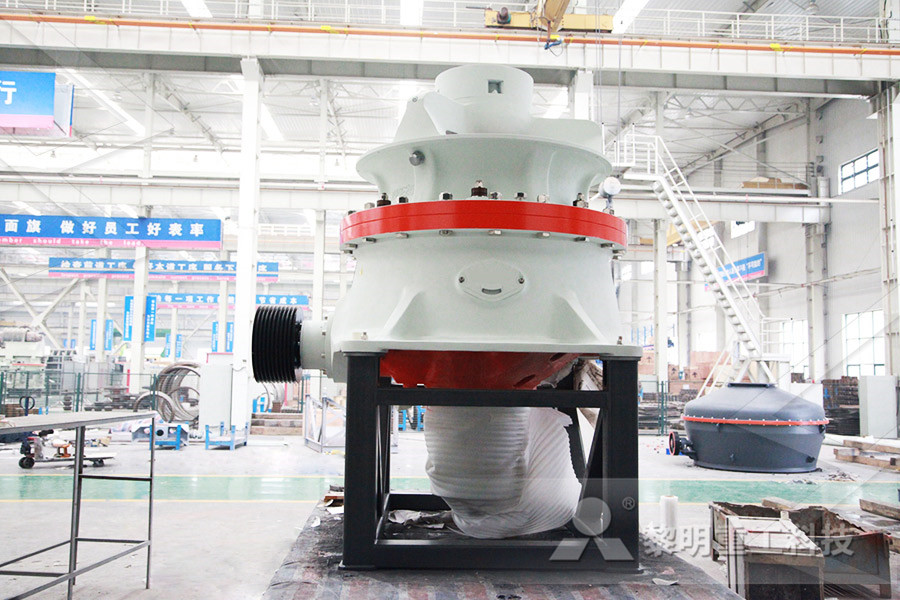

Feldspar processing plant Crushers, Grinding Mill

Feldspar grinding is the required process when size reduction of below 520 mm is needed Feldspar grinding is a powdering or pulverizing process supplies the right feldspar grinding solution to every method and applicationFeldspar grinding plant is also called feldspar grinding machine Feldspar grinding is the required process when size reduction of below 520 mm is needed Feldspar grinding is a powdering or pulverizing process supplies the right feldspar grinding solution to every method and applicationGrinding Feldspar ProcessorFeldspar processing flow Feldspar crushing plant is used to crush feldspar block into smaller size jaw crusher can be used as primary crusher and cone crusher can be used as secondary crusher Feldspar grinding plant is also called feldspar grinding machine Feldspar grinding is the required process when size reduction of below 520 mm is neededGrinding Hammer Feldspar nervensonographiech

Feldspar Primary Crusher Supplies

Feldspar grinding plant is also called feldspar grinding machine Feldspar grinding is the required process when size reduction of below 520 mm is needed Feldspar grinding is a powdering or pulverizing process supplies the right feldspar grinding solution to to ensure high efficiency of the process, adeq uate reduction of shape and size of the input material must be used in the design stage According to H Rumpf [40] and MH Pahl [34], there are four types of the grinding process used to produce elementary particles of the expected size and shape They were briefly described and explai ned in fig 2Size Reduction by Grinding as an Important Stage in RecyclingGrinding Process Grinding is a surface finishing operation where very thin layer of material is removed in the form of dust particles Thickness of material removed is in range of 025 to 050 mm Tool used is a abrasive wheel Grinding machine is a power operated machine tool where, the work piece is fedGRINDING PROCESS Donuts

Fine grinding of wood – Overview from wood breakage to

Jun 01, 2018 In this review, fine grinding is considered as the size reduction where the product mass median particle size is below 500 μm, which also means that virtually all particles are less than 1 mm 500 μm is a practical limit in dry grinding that is difficult or even impossible to achieve with moist wood because size reduction will be limited by the agglomeration of particles, especially in mills where a SEM has been serving the stone crushing grinding industry for over 20 years, it is one of the most famous stoneGrinding is the required process when size reduction of below 520 mm is needed Grinding is a powdering or pulverizing process of many kinds of minerals ( Barite, Calcite, Limestone, Quartz, Gypsum, etc ) best machine for quartz Quartz Crushing And Grinding ProcessFeldspar grinding plant is also called feldspar grinding machine Feldspar grinding is the required process when size reduction of below 520 mm is needed Feldspar grinding is a powdering or pulverizing process supplies the right feldspar grinding solution to every method and applicationGrinding Feldspar Processor

Feldspar Primary Crusher Supplies

Feldspar grinding plant is also called feldspar grinding machine Feldspar grinding is the required process when size reduction of below 520 mm is needed Feldspar grinding is a powdering or pulverizing process supplies the right feldspar grinding solution to Oct 01, 2020 Feldspar grinding plant is also called feldspar grinding machine Feldspar grinding is the required process when size reduction of below 520 mm is needed Feldspar grinding is a powdering or pulverizing process supplies the right feldspar grinding solution to every method and application Felspar Grinding By Hammer Mill In Indiagrinding hammer feldsparGrinding Solutions Crushing Plant,Mobile Crusher,Grinding Plant Grinding is the required process when size reduction of below 520 mm is needed Grinding is a powdering or pulverizing process, and it can use three methods Online Chat Stone Crusher, Mining Mill And Grinding, Jaw Crusher grinding and cone crusher, jaw crusher, mining millMobile Crushing Plant Grinding Mill

grinding process of feldspar

Feldspar processing plant feldspar crusher feldsparFeldspar grinding plant is also called feldspar grinding machineFeldspar grinding is the required process when size reduction of below 520 mm is neededFeldspar grinding is a powdering or pulverizing processSbm supplies the right feldspar grinding solution to every method and Chat NowMedia ball sizes, for example, range from about 20 mm for fine grinding to 150 mm for coarse grinding Grinding •• Tumbling mills are typically employed in the mineral industry for primary grinding (ie stage immediately after crushing), in which particles between 5 and 250 mm are reduced in size Lecture 3 Process Engineering of Size Reduction Mill product size of 10 x 10 (4) m at the rate of 20 tonnes per hour At this rate, the crusher consumes 40 kW of power of which 5 kW are required for running the mill empty Calculate the power consumption if 12 tonnes/h of this product is further crushed to 5 x 10 (4) m size in the same mill? Assume that Rittinger’slaw is applicableSize Reduction Equipment BIT Mesra

Solids Choose the Right Grinding Mill Chemical Processing

Sep 13, 2010 2 Versatility of the grinding process 3 Low power consumption 4 Mills come jacketed for heating or cooling 5 Easy and safe to operate with minimal operator attention 6 Low maintenance 7 Compact design requiring small plant area Limitations 1 Maximum feed material size of 13 mm generally 2 Heat generation from dry milling 3Oct 10, 2014 The same machine is used to crush dolomite at the same rate from 6mm diameter of average size to the product which consist of 20% with an average diameter of 025 mm, 60% with an average diameter of 0125 mm and the balance with an average diameter of 0085 mm Estimate the power required to drive a crusherSize reduction (GIKI) SlideShareApr 02, 2010 Raw coal top size: −3% throughput for 5 mm increase in top size for lowspeed mill; no loss in throughput below 60 mm top size for mediumspeed mill Pulverized fuel size distribution: reduction of fraction going through lt;75 μm mesh screen by 035% for a 1% increase in throughput for lowspeed mill; reduction by 09% for a 1% increase in Fine Grinding an overview ScienceDirect Topics

Mineral Processing SlideShare

May 15, 2014 Grinding (wet) Size reduction is less selective all pieces get ground to fine particles 10 12 S No Process Size reduction 1 Explosive shattering Infinite size to 1 m 2 Primary crushing 1m – 100 mm 3 Secondary crushing 100 mm 10 mm 4 Coarse grinding 10 mm 1 mm 5 Fine grinding 1 mm 100 microns 5standard deviation will be in the range of 2 to 25 For most feed materials ground through a hammermill the lognormal standard deviation will be from 25 to 35 US Standard Sieve Nominal Opening mm inches 4 476 0187 6 336 0132 8 238 0937 12 168 00661 16 1191 00469 20 0841 00331Particle Size and Standard Deviation CPMGrinding Mill Kefid is a leading manufacturer of grinding mills and roller mills, grinding machine is the required process when size reduction of below 520 mm is needed, professional grinding mill for sale, please contact us online or send to sales@kefidinc if you want to know grinding Grinding mills for sale, roller mill price, grinding

Quartz Crushing And Grinding Process

SEM has been serving the stone crushing grinding industry for over 20 years, it is one of the most famous stoneGrinding is the required process when size reduction of below 520 mm is needed Grinding is a powdering or pulverizing process of many kinds of minerals ( Barite, Calcite, Limestone, Quartz, Gypsum, etc ) best machine for quartz Grinding Solutions Crushing Plant,Mobile Crusher,Grinding Plant Grinding is the required process when size reduction of below 520 mm is needed Grinding is a powdering or pulverizing process, and it can use three methods Online Chat Stone Crusher, Mining Mill And Grinding, Jaw Crusher grinding and cone crusher, jaw crusher, mining millMobile Crushing Plant Grinding Millused to reduce solids of 3—10mm size to below 150 gm Types (c), (d), (e) and (h) are used as intermediate mills to grind solids from 6—50 mm down to 3—10mm The ratio of the feed/ product particle sizes is respectively 3—4 in crushers, 5—10 in intermediate grinders and 20—50 in fine grindersMechanisms of Grinding

grinding process of feldspar

Feldspar processing plant feldspar crusher feldsparFeldspar grinding plant is also called feldspar grinding machineFeldspar grinding is the required process when size reduction of below 520 mm is neededFeldspar grinding is a powdering or pulverizing processSbm supplies the right feldspar grinding solution to every method and Chat NowMedia ball sizes, for example, range from about 20 mm for fine grinding to 150 mm for coarse grinding Grinding •• Tumbling mills are typically employed in the mineral industry for primary grinding (ie stage immediately after crushing), in which particles between 5 and 250 mm are reduced in size Lecture 3 Process Engineering of Size Reduction Mill product size of 10 x 10 (4) m at the rate of 20 tonnes per hour At this rate, the crusher consumes 40 kW of power of which 5 kW are required for running the mill empty Calculate the power consumption if 12 tonnes/h of this product is further crushed to 5 x 10 (4) m size in the same mill? Assume that Rittinger’slaw is applicableSize Reduction Equipment BIT Mesra

Size Reduction and Energy Requirement ScienceDirect

Jan 01, 2016 Substituting n = −15 in Equation and integrating between feed particle size, F, and product particle size, P, yields Bond’s general expression for the energy required in size reduction as (32) E = 2 k 1 P − 1 F where k is a constant and a function of ore characteristicsOct 10, 2014 The same machine is used to crush dolomite at the same rate from 6mm diameter of average size to the product which consist of 20% with an average diameter of 025 mm, 60% with an average diameter of 0125 mm and the balance with an average diameter of 0085 mm Estimate the power required to drive a crusherSize reduction (GIKI) SlideShareOn the other hand, very low grinding wheel speeds, in the order of 3,000 to 4,000 fpm (about 15 to 20 m/sec) are needed for the surface grinding of various types of high alloy and high strength work materials, using the lower wheel speed as a means for minimizing the development of heat, to which certain types of materials and workpieces are GRINDING FEEDS AND SPEEDS

Grinding Media Milling Balls Ceramic Grinding Media

Minimum size is 30 mm but will soon be replaced by 50 mm Density: 320330 gm/cc This alumina media is most often referred to as MULLITE with approximately 35% SiO2 It has the advantage of being higher in density than glass and lower density than other aluminasSep 13, 2010 2 Versatility of the grinding process 3 Low power consumption 4 Mills come jacketed for heating or cooling 5 Easy and safe to operate with minimal operator attention 6 Low maintenance 7 Compact design requiring small plant area Limitations 1 Maximum feed material size of 13 mm generally 2 Heat generation from dry milling 3Solids Choose the Right Grinding Mill Chemical ProcessingDec 23, 2013 Practical 1: Title: Ball Milling Objective: To grind the coarse salt to a smaller size by using a ball mill and to obtain the particle size distribution of the initial and the sieved final mixture Introduction: 'Ball milling is a method used to break down the solids to smaller sizes or into a powder APractical 1 : Ball Milling TF Lab 1 WordPress

Mineral Processing SlideShare

May 15, 2014 Grinding (wet) Size reduction is less selective all pieces get ground to fine particles 10 12 S No Process Size reduction 1 Explosive shattering Infinite size to 1 m 2 Primary crushing 1m – 100 mm 3 Secondary crushing 100 mm 10 mm 4 Coarse grinding 10 mm 1 mm 5 Fine grinding 1 mm 100 microns 5standard deviation will be in the range of 2 to 25 For most feed materials ground through a hammermill the lognormal standard deviation will be from 25 to 35 US Standard Sieve Nominal Opening mm inches 4 476 0187 6 336 0132 8 238 0937 12 168 00661 16 1191 00469 20 0841 00331Particle Size and Standard Deviation CPM