separator louvers in cement plant

2021-10-14T20:10:28+00:00

Cement Separator – Cement Mill Separator Cyclone Air

Cement separator, also called cement mill separator, is the necessary equipment in the powder classifying system of cement, chemical, mineral, and other industries It can respectively collect the qualified fine powder and coarse powder from the airflow after they are ground by the grinding equipment to a certain extentplants, lime works, quarry and crushing plants, as 3D model of a cement grinding plant with a ball mill, air separator PRESEP VTP and pair of cyclones 1 4how a separator works in cement millCement mill separator, or cement separator, is a type of equipment that was widely used in the cement grinding system and raw mill system of cement plantsCement Milll Separator Cyclone Air Separator in Cement Plant

VSeparators KHD International

Excellence KHD is a customerfocused engineering, equipment supplier, and service company, providing a fullline of competitive and environmentally friendly technologies to the cement industryKHD, founded back in 1856, is a global leader in cement plant technology, equipment, and services and hence, the right partner for all your demandsWorking Principle of Cement Seperator: The classification chamber of the cyclone type separator is a cylindrical casing made of steel plate In classification chamber, the small blades and the spreading disc are fixed together on the vertical axis The motor is rotated by belt conveyor in the classification chamberCement Seperator for Cement Grinding SystemUpgraded plants show savings in grinding energy of 10 to 20 % on average and production increases of 10 to 25 % for cement raw meal and normal cement Si gnificantly higher production increases of more than 50 % have been achieved in the manufacture of extremely SEPMASTER Process and options Fine material and coarse material are sepa Focus on efficiency KHD Separators

Separator performance Page 1 of 3 CemNet

Separator performance without Tromp curve what is the way to judge the separator performance by seive analysis of rejects,feed fines what is the normal range of residues on 212,90,63,45,32 mic for better efficiency of a separator in coarse,feed fines why?(for cement as well as raw meal) what is the optimum efficiency of a high efficiency separator?Jun 23, 2017 Cement mill seperator Hi my friends We have a closed circuit cement mill and documentary of the seperator is SKSZ3500/290/4*3200 The seperator included of dynamic and static separator The static seperator have 100 blades (50blades in up and50blade in down)Cement mill seperator Page 1 of 1How to Remove and Replace Wood Dividers in Concrete Wood dividers in a concrete sidewalk, driveway or patio aren't just decorative; they serve an important function The dividers are put in place How to Remove and Replace Wood Dividers in Concrete Home

What is a Damper and Louvre ? Dampers versus Louvres

A photograph of a parallelvane damper is shown here, part of an induceddraft (suction) air fan system on a separator at a cement plant The vanes are not visible in this photograph because they reside inside the metal air duct, but the actuator mechanism and linkages connecting seven vane shafts together are: Dampers and LouvresCement mill separator, or cement separator, is a type of equipment that was widely used in the cement grinding system and raw mill system of cement plantsThe function of the separator is to separate the finesized particles from the coarsesized particles, so as to avoid material condensation and over grinding in the mill, and improve the milling system’s grinding efficiencyCement Milll Separator Cyclone Air Separator in Cement PlantCement Seperator Description: JD series seperator is highefficiency combined raw material special powder sorting machine, which is the latest type of powder sorting equipment developed, combined with advanced powder classify technology to apply the plane eddy current theory to the cyclone type separatorCement Seperator for Cement Grinding System

MODERNISING CEMENT GRINDING PLANTS WITH TSV™

MODERNISING CEMENT GRINDING PLANTS WITH TSV™ SEPARATOR Driving Progress Fives FCB March 2009 2 The Fives FCB’s SEPARATOR TTTTurbo CEMENT GRINDING PLANTS N° 1 AND N° 2 Type of cement CEM II AL 325 CEM I 425 composition 78 % ck + 4% gypsum + 18 % limestone 93 % ck + 4% gypsumCement Production Separator cones for cement made of KALMETALL W100 6+4, 3,000 mm Ø Lining pipe parts used for cement grinding with KALCRET BNX, up to 3,200 mm Ø ABRESIST fused cast basalt is a timetested protective material for cement separators Precise fitting of KALOCER high alumina ceramics, 13 and 25 mm thickSolutions for Wear Protection in the Cement IndustryUpgraded plants show savings in grinding energy of 10 to 20 % on average and production increases of 10 to 25 % for cement raw meal and normal cement Si gnificantly higher production increases of more than 50 % have been achieved in the manufacture of extremely SEPMASTER Process and options Fine material and coarse material are sepa Focus on efficiency KHD Separators

Separator performance Page 1 of 3 CemNet

Separator performance without Tromp curve what is the way to judge the separator performance by seive analysis of rejects,feed fines what is the normal range of residues on 212,90,63,45,32 mic for better efficiency of a separator in coarse,feed fines why?(for cement as well as raw meal) what is the optimum efficiency of a high efficiency separator?The working principle of the air separator cement function of v separator in cement mill crusher plant spare parts accessories function of v separator in cement mill cement plant report STATIC SEPARATORS 11 Cyclone 111 Principle of Operation Air with 63600 d [m] Function Of Ball Mill For Cement Production Pptin cement mill separator function and principleJun 24, 2017 Cement mill seperator Hi my friends We have a closed circuit cement mill and documentary of the seperator is SKSZ3500/290/4*3200 The seperator included of dynamic and static separator The static seperator have 100 blades (50blades in up and50blade in down)Cement mill seperator Page 1 of 1

How to Remove and Replace Wood Dividers in Concrete Home

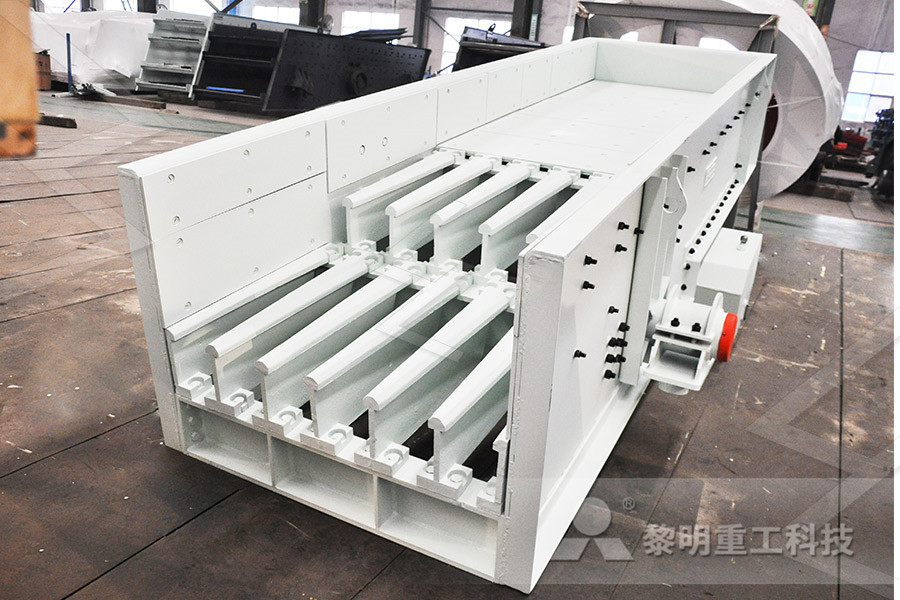

How to Remove and Replace Wood Dividers in Concrete Wood dividers in a concrete sidewalk, driveway or patio aren't just decorative; they serve an important function The dividers are put in place Coal Mill 2 Separator SINAI CEMENT PLANT 08/08/2020 Coal Mill 2 Separator SINAI CEMENT PLANT Scope of Works: Change separator rotor; Adjust the top seal clearance; Change all louvers; Change all wear plates; Repair worn out steel parts at reject cone and reject chutDate : July 2020 You may be also interested in 25 February، 2021cement mill separator rotorSuccessful separator modernization at a cement grinding plant in Schelklingen By installing a new rotating cage, an improved louver ring, and a blocking air seal, the cement works in Schelklingen achieved significant improvements in throughput and specific energy needsprefix Separation Christian Pfeiffer

New highefficiency separator for Phoenix Cement Cement

Today’s greatly increased demands on cement quality, particularly on its strength, induced Phoenix to equip cement grinding plant 1 with a new separator, a rotor separator with transversely inflowing separating air It was decided to install a highefficiency separator, the QDK 29NZ from Christian Pfeiffer (Tables 1 and 2)cement quality SEPARATORS : THE THREE GENERATIONS THE FIRST GENERATION THE SECOND GENERATION Examples: KHD (zub models) O K Polysius Cyclopol Advantages: 1 With an external fan and small cyclones, most of the drawbacks of SEPARATORS Walchandnagar IndustriesSuccessful separator modernization at a cement grinding plant in Schelklingen By installing a new rotating cage, an improved louver ring, and a blocking air seal, the cement works in Schelklingen achieved significant improvements in throughput and specific energy needsprefix Separation Christian Pfeiffer

MODERNISING CEMENT GRINDING PLANTS WITH TSV™

MODERNISING CEMENT GRINDING PLANTS WITH TSV™ SEPARATOR Driving Progress Fives FCB March 2009 2 The Fives FCB’s SEPARATOR TTTTurbo CEMENT GRINDING PLANTS N° 1 AND N° 2 Type of cement CEM II AL 325 CEM I 425 composition 78 % ck + 4% gypsum + 18 % limestone 93 % ck + 4% gypsumToday’s greatly increased demands on cement quality, particularly on its strength, induced Phoenix to equip cement grinding plant 1 with a new separator, a rotor separator with transversely inflowing separating air It was decided to install a highefficiency separator, the QDK 29NZ from Christian Pfeiffer (Tables 1 and 2)New highefficiency separator for Phoenix Cement Cement Cement Production Separator cones for cement made of KALMETALL W100 6+4, 3,000 mm Ø Lining pipe parts used for cement grinding with KALCRET BNX, up to 3,200 mm Ø ABRESIST fused cast basalt is a timetested protective material for cement separators Precise fitting of KALOCER high alumina ceramics, 13 and 25 mm thickSolutions for Wear Protection in the Cement Industry

Focus on efficiency KHD Separators

Upgraded plants show savings in grinding energy of 10 to 20 % on average and production increases of 10 to 25 % for cement raw meal and normal cement Si gnificantly higher production increases of more than 50 % have been achieved in the manufacture of extremely SEPMASTER Process and options Fine material and coarse material are sepa Jun 24, 2017 Cement mill seperator Hi my friends We have a closed circuit cement mill and documentary of the seperator is SKSZ3500/290/4*3200 The seperator included of dynamic and static separator The static seperator have 100 blades (50blades in up and50blade in down)Cement mill seperator Page 1 of 1The working principle of the air separator cement function of v separator in cement mill crusher plant spare parts accessories function of v separator in cement mill cement plant report STATIC SEPARATORS 11 Cyclone 111 Principle of Operation Air with 63600 d [m] Function Of Ball Mill For Cement Production Pptin cement mill separator function and principle

Cement Rotary Kiln Cement Equipment In Cement Plant

Cement rotary kilns refer to cement rotary calcining kilns (sometimes called rotary furnaces) It is a pyroprocessing device used to heat materials to high temperatures in a continuous process The kiln body is a cylinder vessel with a certain degree of tilt to the horizontal levelAug 30, 2012 Now cement plant grind the raw mix with the help of heavy wheel type rollers and rotating table Rotating table rotates continuously under the roller and brought the raw mix in contact with the roller Roller crushes the material to a fine powder and finishes the job Raw mix is stored in a prehomogenization pile after grinding raw mix to fine Cement Manufacturing Process Phases Flow Chart How to Remove and Replace Wood Dividers in Concrete Wood dividers in a concrete sidewalk, driveway or patio aren't just decorative; they serve an important function The dividers are put in place How to Remove and Replace Wood Dividers in Concrete Home

What Parts Deserved Wear Protection in Cement Plant

Sep 14, 2018 What Parts Deserved Wear Protection in Cement Plant Ceramics concluded the cement parts like chute, hopper in limestone crushing and raw fuel preblending systemcyclone, separator, fan impeller and shell , mill outlet elbow in raw fuel grinding , TrimASlab 125in x 075in x 50ft Polyvinyl Concrete Expansion Joints TrimASlab is a product made from exteriorgrade materials designed to replace rotten or missing wood often found in driveways and sidewalks over 5 years old It offers many advantages over the tubedispensed gooey stuff that has been about the only option available for Concrete Expansion Joints at Lowescement quality SEPARATORS : THE THREE GENERATIONS THE FIRST GENERATION THE SECOND GENERATION Examples: KHD (zub models) O K Polysius Cyclopol Advantages: 1 With an external fan and small cyclones, most of the drawbacks of SEPARATORS Walchandnagar Industries

Applying Gemba Kaizen at SKS Separator in cement plant: A

Applying Gemba Kaizen at SKS Separator in cement plant: A case study 3 P a g e Steps to Improvement 1 Select the dates, times and venue for the kaizen event as well as an industry established consultant to lead the event Be sure to select a time of year that is slow for the company, as the event will take the bulk of