The Role Of Vertical Raw Mill

2020-04-07T17:04:19+00:00

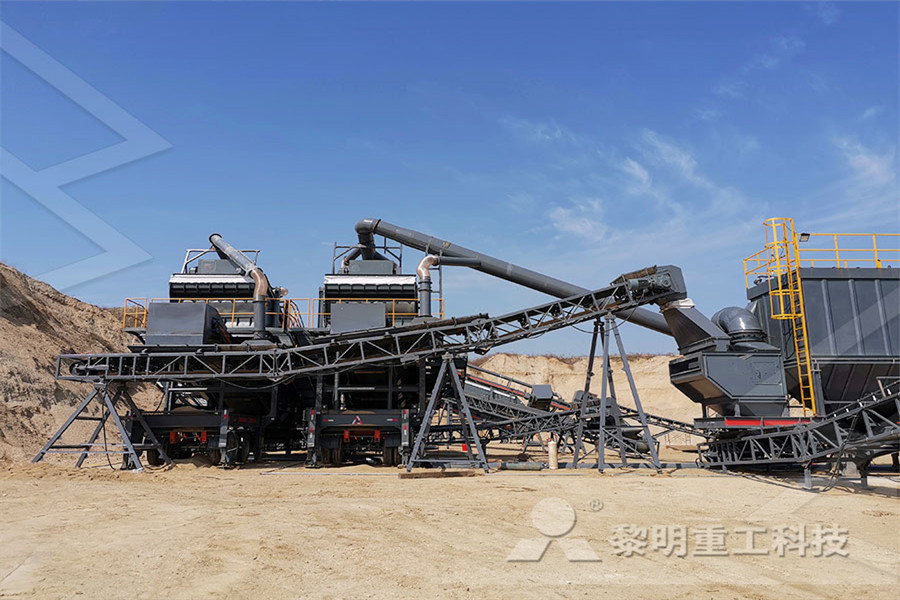

Vertical Raw Mill for Cement Raw Meal Grinding in Cement

Because the vertical raw mill is the use of roller grinding principle to crush materials, its vertical raw mill operation is more efficient and energysaving, product output is more stable, so in cement industry, electric power, metallurgy, chemical industry, metal, and May 15, 2013 30 12 Control of grinding pressure: the pressure is affecting thegrinding mill out put,power mill grinding efficiency and themain factor vertical roller mill is to impose by means of thematerial bed crushing pressure and the pressure toincrease Vertical raw mill pradeep kumar SlideShareA raw mill is the equipment used to grind raw materials into " rawmix " during the manufacture of cement Rawmix is then fed to a cement kiln, which transforms it into Rawmill Wikipedia

Optimization of VRM Operation RUCEMRU

Vertical Roller Mills What is a Grinding Bed ? Grinding bed is the material layer between the roller and the table It transmits the entire roller force and mill power It is the key issue to successful operating of a VRM !!! Determined by: •Feed Material size •Feed Material Moisture •Dam Ring Height •Grinding Fineness •Air Speed in Vertical roller mill is a type of grinder used to grind materials into extremely fine powder for use in mineral dressing processes, paints, pyrotechnics, cements and ceramics It Vertical roller mill Wikipediavertical raw mill operation WQM is proudly owned and operated by experienced members of the vertical raw mill operation and Mobile by an electric motor or possibly a hydraulicHydraulic Operation In Vertical Raw Mill

Cement mills and raw mills for high throughput rates

The highest wear occurs on the wear parts of the grinding elements as is the case with any type of vertical mill Therefore, ease of replacement and regeneration is a major feature of the mill The MVR mill has a modern hydraulic system used in operation and for maintenance alikeThere are 3 basic types of waterwheels: horizontal, undershot, and overshot Horizontal waterwheels revolve in the horizontal plane (which means, confusingly, their axles are vertical) much like a topload washing machine The undershot and overshot waterwheels are both types of vertical waterwheels, which rotate like a Ferris wheel The undershot wheel's lower blades or paddles dip into the Geography, Landscape and Mills Pennsylvania State UniversityNov 05, 2014 vertical Raw Mill operation control Dears plese i need short notce about how to operat and control Vertical Raw Mill spicialy the oil pressure Reply Know the answer to this question? Join the community and register for a free guest account to post a replyvertical Raw Mill operation control Page 1 of 1

Vertical raw mill pradeep kumar SlideShare

May 15, 2013 Vertical mill 6 General Design 7 material to air ratio,05 – 06 kgs/m3 8 Vertical mills of various suppliersLoeschemillRaymond milFLS Atox millGebr Pfeiffer , MPSKrupp PolysiusWilliams millCP Mill (claudius Peters)Babcock E ring mill 9 Raw mills Introduction : Vertical raw mill is a type of industrial equipment used to crush or grind materials into small particlesVertical roller mills are widely used in the concrete and mining fields, and are also used to process gypsum These units can process both raw Vertical Raw Mill Great Wallhydraulic system in vertical roller mill gmecrusher Hydraulic System For Fls Raw Mill Vertical roller mill hydraulic system of the proper use the grinding force during operation, the roller basic mill Hydraulic Operation In Vertical Raw Mill

(PDF) Performance Evaluation of Vertical Roller Mill in

Recent decades have proven the great effectiveness of a vertical roller mill for grinding raw materials Material characterization plays a crucial role by means of equipments efficiency and The highest wear occurs on the wear parts of the grinding elements as is the case with any type of vertical mill Therefore, ease of replacement and regeneration is a major feature of the mill The MVR mill has a modern hydraulic system used in operation and for maintenance alikeCement mills and raw mills for high throughput ratesFor raw materials and cement clinker, the vertical roller mill is an excellent grinding solution because of the relatively lower cost of installation, ease of operation and maintenance, energy efficiency and product quality Further, our vertical roller mill solution for cement grinding has an ability to dry, grind and separate within a single Vertical Roller Mills

Cement grinding Vertical roller mills versus ball mills

80 years it was the predominant mill for grinding of raw materials and coal, and still today is the most used mill for cement grinding Over the last three decades the vertical roller mill has become the preferred mill for grinding of raw materials The grinding efficiency of the vertical roller mill combinedMar 25, 2015 Hydraulic system vertical roller mill operation 1 The working principle of the hydraulic system vertical roller mill The hydraulic system ofvertical mill is an important system, the main function ofthe hydraulic system is to break the grinding roller, which is when the internal grinding cavity wear parts wear, can stop open on both sidesofthe grinding roller mill, to replace the inside Hydraulic system vertical roller mill operationThe cement raw material mixtures are ground, dried, and classified in the Pfeiffer vertical roller mill For drying the material, hot gases are directed into the mill Product fineness can be adjusted within a wide range (0063 to 02 mm)Raw mills for all requirements Gebr Pfeiffer

vertical Raw Mill operation control Page 1 of 1

Nov 05, 2014 vertical Raw Mill operation control Dears plese i need short notce about how to operat and control Vertical Raw Mill spicialy the oil pressure Reply Know the answer to this question? Join the community and register for a free guest account to post a replyVertical roller mill is a kind of grinding machine for cement, raw material, cement clinker, slag and coal slag It has the features of simple structure and low cost of manufacture and use Vertical roller mill has many different forms, but it works basically the same All of these forms of machine come with a roller (or the equivalent of Vertical roller mill WikipediaVertical Roller Mill Production Line mainly consists of the grinder, dust collector, hot air stove, bucket elevator, feeder, hopper etc When it works, raw materials are fed in evenly by the feeder at the bottom of the hopper, then lifted to appropriate height by the bucket elevator, then sent into the mill through feeding pipe to be grinded , the grinded materials are brought into the powder Vertical Roller Mill Production Line greatwallcrusher

Pinch roll used in rolling mill line

May 18, 2017 Billets pinch roll used in rolling mill line Role: arranged before the roughing mill For holding the rolling stock, so that the rolling stock to maintain a certain tension and stable forward LM series vertical mill is mainly composed of a powder concentrator, a roller device, an abrasive disk device, a pressure device, a speed reducer, a electric motor and a housing Separtor is a kind of efficient and energysaving powder concentrator The roller is a Vertical Roller Mill Structure And Working PrincipleVertical roller mill is a kind of grinding machine for cement, raw material, cement clinker, slag and coal slag It has the features of simple structure and low cost of manufacture and use Vertical roller mill has many different forms, but it works basically the same All Vertical roller mill Wikipedia

Vertical Roller Mill Structure And Working Principle

LM series vertical mill is mainly composed of a powder concentrator, a roller device, an abrasive disk device, a pressure device, a speed reducer, a electric motor and a housing Separtor is a kind of efficient and energysaving powder concentrator The roller is a Recent decades have proven the great effectiveness of a vertical roller mill for grinding raw materials Material characterization plays a crucial role by means of equipments efficiency and (PDF) Performance Evaluation of Vertical Roller Mill in For raw materials and cement clinker, the vertical roller mill is an excellent grinding solution because of the relatively lower cost of installation, ease of operation and maintenance, energy efficiency and product quality Further, our vertical roller mill solution for cement grinding has an ability to dry, grind and separate within a single Vertical Roller Mills

Cement grinding Vertical roller mills versus ball mills

80 years it was the predominant mill for grinding of raw materials and coal, and still today is the most used mill for cement grinding Over the last three decades the vertical roller mill has become the preferred mill for grinding of raw materials The grinding efficiency of the vertical roller mill combinedGrinding of cement raw material – material separation in cyclones The cement raw material mixtures are ground, dried, and classified in the Pfeiffer vertical roller mill For drying the material, hot gases are directed into the mill Product fineness can be adjusted within a wide range (0063 to 02 mm)Raw mills for all requirements Gebr PfeifferVertical Roller Mills (VRMs) have been the standard option for raw materials grinding in the cement industry for several decades has supplied the global cement industry with leading VRM designs for all applications since they were first brought to market The OK™ mill has been ’s standard cement VRM since 1993OK™ raw mill Reliable and efficient raw material grinding

Hydraulic system vertical roller mill operation

Mar 25, 2015 Hydraulic system vertical roller mill operation 1 The working principle of the hydraulic system vertical roller mill The hydraulic system ofvertical mill is an important system, the main function ofthe hydraulic system is to break the grinding roller, which is when the internal grinding cavity wear parts wear, can stop open on both sidesofthe grinding roller mill, to replace the inside Nov 05, 2014 vertical Raw Mill operation control Dears plese i need short notce about how to operat and control Vertical Raw Mill spicialy the oil pressure Reply Know the answer to this question? Join the community and register for a free guest account to post a replyvertical Raw Mill operation control Page 1 of 1May 18, 2017 Billets pinch roll used in rolling mill line Role: arranged before the roughing mill For holding the rolling stock, so that the rolling stock to maintain a certain tension and stable forward Pinch roll used in rolling mill line

HLM Vertical Roller Mill hcmilling

HLM Series vertical roller mill is a kind of advanced mill developed by Hongcheng based on two decades of RD experience and introduction of foreign advanced technology It features in a combination of drying, grinding, classifying and conveying HLM vertical grinding mill, has high grinding efficiency, low power consumption, large feed size, product fineness easy adjustment, equipment process Cement Mill, Vertical Raw Mill # 4, Hydraulic System 1 2 Oil Type: ISO VG 68, Tellus68 Capacity: 2 x 1,680 Liters THE PROBLEM Holcim Philippines Bulacan Plant is doing a quarterly machine condition monitoring through oil analysis On May 15, 2012, they found out that the oil in the Hydraulic System 1 2 on Raw Mill #4 was heavCement Mill, Vertical Raw Mill, Hydraulic SystemThe largest component of the vertical raw mill is the grinding table and it plays important roles in the overall performance of the vertical mill The design of the grinding table revolves around the grinding capacity, grinding speed, and space setting The grinding capacity of the vertical milling machine is directly related to the working Vertical Roller Mill for Cement Raw Material SINOMALY

FOR CEMENT RAW MATERIAL Loesche

Cement raw material has been almost exclusively ground in roller mills (vertical airswept grinding mills) since the second half of the 20th century Loesche was and is the pioneer of this technology Hundreds of Loesche mills have been used in the cement industry across the world to the present day They operate with two, three, four and six