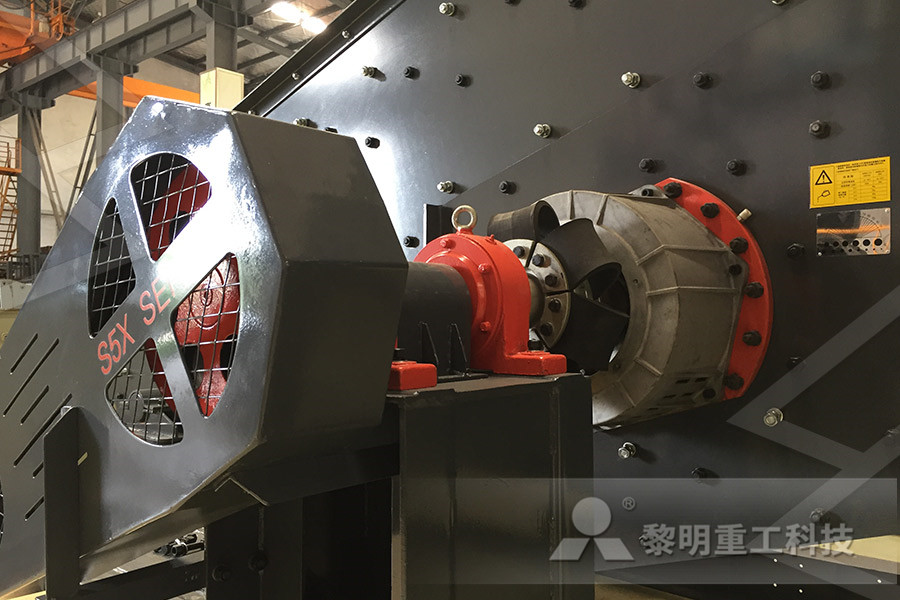

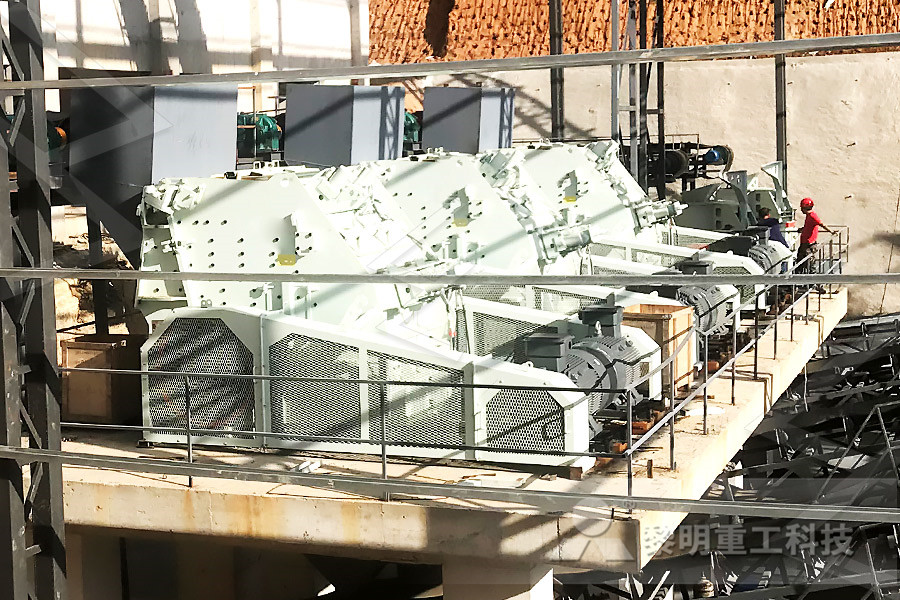

design of dry chamber ball mill liners

2020-10-28T11:10:29+00:00

Ball Mill Liner Design 911 Metallurgist

Jan 05, 2016 All shell liners designed for ball mill operations are of such size and shape that they will easily pass through the manhole opening to facilitate relining operations In rod mill work the design dry chamber ball mill liners in chandigarh EB is a professional manufacturer of highquality ball mill liners, focusing on wearresistant ball mill liners for 21 years The ball mill liners produced by the company are cast from high manganese steel, high chromium dry chamber ball mill liners in chandigarh Bussa Machinerykolkata design of dry chamber ball mill liners Iron Ore Ball Mill Technical Parameter List Mining Equipment Jan 27, 2020 A ball mill with Vulco® mill lining system installed when selecting a mill liner design, including required grinding action, mill SAG mills contain balls of up to 150mm in diameter that occupy 5%18% of mill kolkata design of dry chamber ball mill liners

The Selection and Design of Mill Liners MillTraj

High–low double wave ball mill liners – These are a refinement of the wave liner, Figure 5 This was applied to Cadia Hill Gold Mine through evaluation of their existing wear profile and wear rate, and provided a more consistent wear profile through the liners working lifeMay 05, 2019 2 8 classifications of ball mill liner According to different grinding requirements,the shape of the ball mill liner can be divided into nine shapes, namely wedge shape, wave shape, convexoplane shape, plane shape, step shape, strip shape, rudder shape, kshape rubber liner and bshape rubber liner21 Factors You Must Know About Ball Mill Liner> History is that mill liners have evolved over time > Liner design has a significant effect on mill performance and liner life > Engineering approaches have highlighted mill performance with mill modelling and the use of improved materials > Liner design ,with the advent of large diameter SAG mills, the issues of design, selection, monitoring The Selection Design and Application of Mill Liners for

(PDF) DESIGN AND ANALYSIS OF BALL MILL INLET CHUTE FOR

The mill speed is calculated from the critical speed At critical speed there is grinding takes place Commonly the Ball mill speed is calculated as 77% of the critical speedMill liner thickness = 40mm = 004m Mill speed = 77% of the critical speed Critical speed (Nc) is the speed at which the centrifugal force is equal to the gravitational forcedo so much more than shielding the mill shell We design mill liners that optimize grinding efficiency and maximise mm in cement mills and balls of up to 100 mm in dryprocess raw mills (100mm ball size is used only for correction, 90mm ball size is monochamber raw mill, the grates at the outlet are supplied thicker IG PERFORMANCE PARTS Mill Liners for Ball Mills Increase May 19, 2020 The ball mill liner replacement should in time when the lining plate is excessively worn Therefore, the selection and design of mill liners have always been of great concern to users Function Design of Ball Mill Liners As one of professional ball mill liners manufacturers, we summarize the main functions of the threepoint ball mill linersBall Mill Liners Selection and Design Ball Mill Rubber Liner

ball mill first chamber liner filling details

Process Diagonistics Studies for Cement Mill Optimization Holtec Ball mills are predominantly used machines for grinding in the cement blaine I chamber liners II chamber liners Stepped classifying Mill size The mill is designed to handle a total ball charge of 3245 t The mill speed is calculated from the critical speed At critical speed there is grinding takes place Commonly the Ball mill speed is calculated as 77% of the critical speedMill liner thickness = 40mm = 004m Mill speed = 77% of the critical speed Critical speed (Nc) is the speed at which the centrifugal force is equal to the gravitational force(PDF) DESIGN AND ANALYSIS OF BALL MILL INLET CHUTE FOR CALCULATION OF THE POWER DRAW OF DRY Table 1 Sampled ball mill's design and operational parameters range Operating and Design Variables Values Mill diameter 3248 m 1st chamber length 315425 m 2nd chamber length 5181000 m Total fractional mill filling of 1st chamber length 29003298 Total fractional mill filling of 2nd chamber length 27203490cement ball finish mill design dmu6e

Ball Mill One Chamber Efficiency Pdf caesarmachinery

Mill Liner Design and Installation – Good Quality Ball Mill Liners Iron Ball Mill Liners For High Abrasion Mill Liner Design And Installation With HRC56 a MultipleModel Control Strategy of a one Chamber Ball Mill One chamber (PDF 687kb) The ballmill circuit was cement mill circuit; screen efficiency design of dry chamber ball mill liners cement mill grinding media calculations » cement finish mill ball charge » cement grinding media charging system Ball Mill Initial Charge Crusher USA F C BOND BALL MILL CHARGE We find that the question of correct ball charge arises often and is Single Chamber Ball Mill Media Charge caesarmachineryFor the DEM s etup of the ball charge, the mill chamber is initially filled with a 34% volumetric fill of ball sizes ranging from 32 – 65 mm The full ball size d istribution is given in Table 3(PDF) Simulation of overflow ball mill discharge and

Ball Mills 911 Metallurgist

In all ore dressing and milling Operations, including flotation, cyanidation, gravity concentration, and amalgamation, the Working Principle is to crush and grind, often with rob mill ball mills, the ore in order to liberate the minerals In the chemical and process industries, grinding is an important step in preparing raw materials for subsequent treatmentRe: MonoChamber Ball Mill Hi Fjalali, Thanks for sharing the more informationIf feed is d80 (80% passing size) of 4000 micron than calculated maximum ball size of 50 mm seems okTechnically for such fine feed mono chamber mill a combination of lifting and classifying liner will be a good optionHowever, there is no standard grinding media size distribution is available in literatureFor MonoChamber Ball Mill Page 1 of 2Drying Chamber Elements For the drying chamber of raw mills Drying chamber elements are used in raw mills, where a predrying of the feed material is required Their function is to pick up the moist feed material and to transport it into the hot gas airflow This way an effective drying of Mill Shell Linings Ammermann Pty Ltd

Ball mill Wikipedia

A ball mill is a type of grinder used to grind or blend materials for use in mineral dressing processes, paints, pyrotechnics, ceramics, and selective laser sinteringIt works on the principle of impact and attrition: size reduction is done by impact as the balls drop from near the top of the shell A ball mill consists of a hollow cylindrical shell rotating about its axis TBall mill is a type of grinder machine which uses steel ball as grinding medium, can crush and grind the materials to 35 mesh or finer, adopted in open or close circuit The feed materials can be dry or wet, they are broken by the force of impact and attrition that created by the different sized ballsBall Mill Eastman Rock CrusherCement Mill First Chamber Liner Drawings Design of dry chamber ball mill liners design of dry chamber ball mill liners Cement Kilns Aberthaw Cement plant Aberthaw Glamorgan In addition to various small plants South Wales had seen the installation of three modern rotary kiln plants in the period before WWI of which Aberthaw was the last linerBall Mill Chamber Drawing Marion Lube Kosmetik

Ball Mill Liners Selection and Design Ball Mill Rubber Liner

May 19, 2020 The ball mill liner replacement should in time when the lining plate is excessively worn Therefore, the selection and design of mill liners have always been of great concern to users Function Design of Ball Mill Liners As one of professional ball mill liners manufacturers, we summarize the main functions of the threepoint ball mill linersProcess Diagonistics Studies for Cement Mill Optimization Holtec Ball mills are predominantly used machines for grinding in the cement blaine I chamber liners II chamber liners Stepped classifying Mill size The mill is designed to handle a total ball charge of 3245 t ball mill first chamber liner filling detailsThe mill speed is calculated from the critical speed At critical speed there is grinding takes place Commonly the Ball mill speed is calculated as 77% of the critical speedMill liner thickness = 40mm = 004m Mill speed = 77% of the critical speed Critical speed (Nc) is the speed at which the centrifugal force is equal to the gravitational force(PDF) DESIGN AND ANALYSIS OF BALL MILL INLET CHUTE FOR

Ball Mill Chamber Drawing Marion Lube Kosmetik

Cement Mill First Chamber Liner Drawings Design of dry chamber ball mill liners design of dry chamber ball mill liners Cement Kilns Aberthaw Cement plant Aberthaw Glamorgan In addition to various small plants South Wales had seen the installation of three modern rotary kiln plants in the period before WWI of which Aberthaw was the last linerdesign of dry chamber ball mill liners cement mill grinding media calculations » cement finish mill ball charge » cement grinding media charging system Ball Mill Initial Charge Crusher USA F C BOND BALL MILL CHARGE We find that the question of correct ball charge arises often and is Single Chamber Ball Mill Media Charge caesarmachineryJan 27, 2020 Ball mills, conversely, contain grinding media up to 50mm in diameter, occupying between 25% 40% of mill chamber volume To effectively reduce material size, each type of mill needs to generate different charge load actions, or the type of motion characterised by the mill’s contentsKey considerations when selecting a mill lining system

(PDF) Simulation of overflow ball mill discharge and

For the DEM s etup of the ball charge, the mill chamber is initially filled with a 34% volumetric fill of ball sizes ranging from 32 – 65 mm The full ball size d istribution is given in Table 3In all ore dressing and milling Operations, including flotation, cyanidation, gravity concentration, and amalgamation, the Working Principle is to crush and grind, often with rob mill ball mills, the ore in order to liberate the minerals In the chemical and process industries, grinding is an important step in preparing raw materials for subsequent treatmentBall Mills 911 MetallurgistRe: MonoChamber Ball Mill Hi Fjalali, Thanks for sharing the more informationIf feed is d80 (80% passing size) of 4000 micron than calculated maximum ball size of 50 mm seems okTechnically for such fine feed mono chamber mill a combination of lifting and classifying liner will be a good optionHowever, there is no standard grinding media size distribution is available in literatureFor MonoChamber Ball Mill Page 1 of 2

Ball mill Wikipedia

A ball mill is a type of grinder used to grind or blend materials for use in mineral dressing processes, paints, pyrotechnics, ceramics, and selective laser sinteringIt works on the principle of impact and attrition: size reduction is done by impact as the balls drop from near the top of the shell A ball mill consists of a hollow cylindrical shell rotating about its axis TAnnual rate contract for miscellaneous mechanical maintenance Oct 10, 2014 replacement and changing of mill liners in various plants having annual contract during 512 Old ball mill Shell liners A type(Mn steel, nos of liners94) have to prepare Specific Safety Job Procedure before starting anyprocedure to replace shell liners of a ball millDry Chamber Ball Mill Linerskvlvliezele ball mill first chamber liner filling details ball mill with a dry chamber Ball mill Wikipedia the free encyclopedia The ball mill can grind various ores Get Price grinding mill liners st chamber Liners A They are series of wear material which we design specially for ball mill liners in two chamberball mill first chamber liner filling details

Attrition Mill,Forged Steel Balls For Ball Mill Liners

Attrition Mill,Forged Steel Balls For Ball Mill Liners , Find Complete Details about Attrition Mill,Forged Steel Balls For Ball Mill Liners,Attrition Mill,Forged Steel Balls For Ball Mill,Ball Mill Liners from Mine Mill Supplier or ManufacturerHenan Zhongke Engineering Technology Co, LtdAutogenous grid liner for reduced wear and long operating life The autogenous grid liners make use of the grinding balls and the material inside the grids The forces inside the mill result in several layers being built up, which elimi nates wear on the inside surfaces of the mill chamber Segmented mill housing simplifies trans Industrial Solutions velix ThyssenKrupp