hydraulic unit of hammer removing device of crusher

2022-01-19T18:01:56+00:00

Hydraulic Unit Of Hammer Removing Device Of Crusher

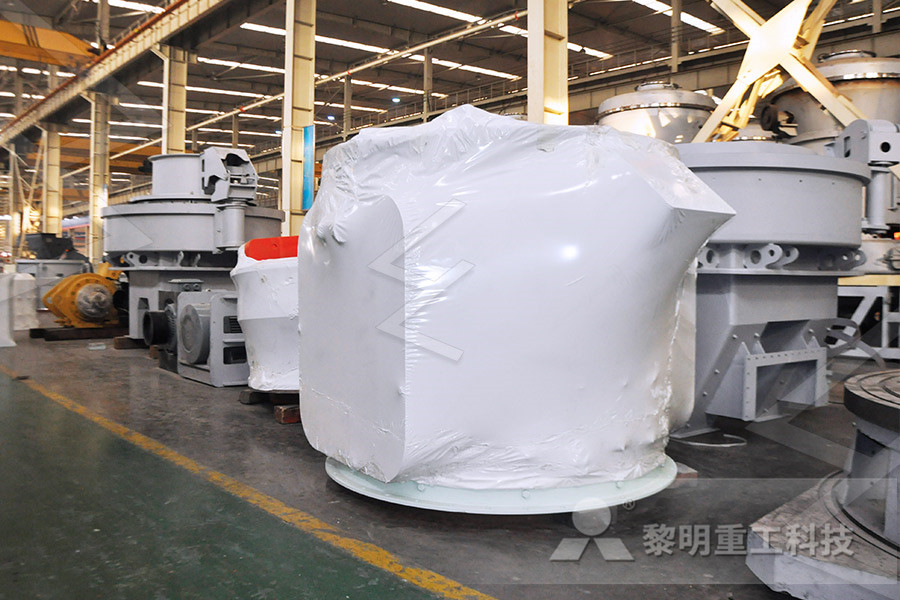

Wheel type Mobile Cone Crusher is the cone crusher with advanced technology (spring cone crusher or multi cyclinder hydraulic cone crusher is also optional) It is equipped with closed side adjustment device, which can quickly adjust settings for production of final product wtih size 10 45 mmHydraulic Unit Of Hammer Removing Device Of Crusher Hydraulic Hammer For Stone Crusher Unit Stone, a hydraulics power unit for stone crsher description hydraulic unit of hammer removing device of crusher 6 Get Price And Support Online; Crusher Wikipedia A crusher is a machine designed to reduce large rocks into smaller rocks, gravel, or hydraulic unit of hammer removing device of crusher• Hammers Have Four Crushing Positions to Maintain a Feeder with Quick Removal Hopper • 6’x16’ DoubleDeck Incline Screen unit and hydraulic cylinders are provided as standard for opening the hood, giving maximum space for maintenance Rotor and hood locking devices areIMPACT CRUSHERS Power Equipment Company

Hammermill Crushers McLanahan

Not only can McLanahan offer hydraulic adjustment, the same hydraulic power unit can be used to open and close the access hatch for inspection and maintenance When a Hammermill is selected and recommended for a specific application, the crushing chamber with grates, impact plates and the hammers will be taken into account in the valuation of 5 Construction, Working and Maintenance of Crushers for Crushing Bulk Materials In a nonreversible hammer mill with screen bars, shown in above figure, material is broken first by impact between hammers and breaker plates and then by a Construction, Working and Maintenance of Crushers for hydraulic unit of hammer removing device of crusher If a piping of the excavator Raw material of various sizes are brought to the primary crusher by rear This is the RockLabs hydraulic crusher/splitter system Inquire Now; primary crusher for high clay lignite primary crusher for hydraulic piping primary crusher

Primary Crusher an overview ScienceDirect Topics

A design for a hammer crusher (Figure 26) allows essentially a decrease of the elevated pressure of air in the crusher discharging unit [5] The Azone beneath the screen is communicated through the hollow ribs and openings in the body side walls with the Bzone 1 The crusher prevents excessive oil temperature The temperature of the hydraulic system of the hydraulic cone crusher is generally suitable in the range of 35 °C 60 °C according to the experiment, and the maximum should not exceed 80 °C At normal oil temperatures, the crusher hydraulic oil has a variety of propertiesMaintenance of Hydraulic System of Cone Crusher (2 The LSI 511V is a very rugged oversized cutter with reinforced aluminum cylinder body for high cutting frequency and mobile applications Double the cutting force of the other tools The tool is hand operated: Simply twist valve or press push buttons to open or to close the bladesElectric Hydraulic Tools (Cutters, Benders, Crushers)

200 tons of hydraulic crushed giant hammer? YouTube

Aug 20, 2019 200 tons of hydraulic crushed giant hammer?• Hammers Have Four Crushing Positions to Maintain a Feeder with Quick Removal Hopper • 6’x16’ DoubleDeck Incline Screen unit and hydraulic cylinders are provided as standard for opening the hood, giving maximum space for maintenance Rotor and hood locking devices areIMPACT CRUSHERS Power Equipment CompanyA design for a hammer crusher (Figure 26) allows essentially a decrease of the elevated pressure of air in the crusher discharging unit [5] The Azone beneath the screen is communicated through the hollow ribs and openings in the body side walls with the Bzone Primary Crusher an overview ScienceDirect Topics

Impact Crusher Hammer Locking Device

Impact Crusher Hammer Locking Device Pfw series small impact crusher is the largest crushing equipment of heavy duty rotor design and unique hammer locking device small impact crusher stone crusher portable devices area unit jaw crusher impact device cone device mobile device plant then on small lime crusher readThese include a new rotor position and locking device, new hammer locking wedges for quicker removal and fitting, and a new wedge removal tool to provide safer installation and removal Sandvik QI442 mobile impact crusher will give you high reduction ratios, superb product shape and unsurpassed productivity This model is also available with Sandvik QI442 Impact CrusherMaintenance Procedure for hammer changing Removing the hammersrotor is at standstillopen the maintenance doorsmove the rotor with the rotor turning devicesecure the rotor in the desired positiondemount the cover of the hammer axisfix the hammer axis pulling device to the machineconnect the pull rod to the hammer axisfix the hammers in Hammer Crushers General Bearing (Mechanical

Crusher Wikipedia

A crusher is a machine designed to reduce large rocks into smaller rocks, gravel, sand or rock dust Crushers may be used to reduce the size, or change the form, of waste materials so they can be more easily disposed of or recycled, or to reduce the size of a solid mix of raw materials (as in rock ore), so that pieces of different composition can be differentiated— Quick maintenance thanks to hydraulic hood opening and hammer pins extraction jack to easily remove wear parts APPLICATIONS FCB VIF™ Crusher is designed for primary and secondary applications Example for mediumhard limestone: — imary application, FCB VIF™ Crusher is fitted withIn pr an inertia flywheel and can accept over 1 m 3 FCB VIF™ CrusherApprox Rs 15 Lakh / Unit Get Latest Price In addition to manufacturing roll crusher we are engaged in the manufacture,supply and export of a broad assortment of Industrial Crushers The Roll Crusher is commonly used in mining industries for ore crushing with even distribution of product size It facilitates adjustment of particle size of final output It produces fine particles without Industrial Crushers Hammer Mill Machine Manufacturer

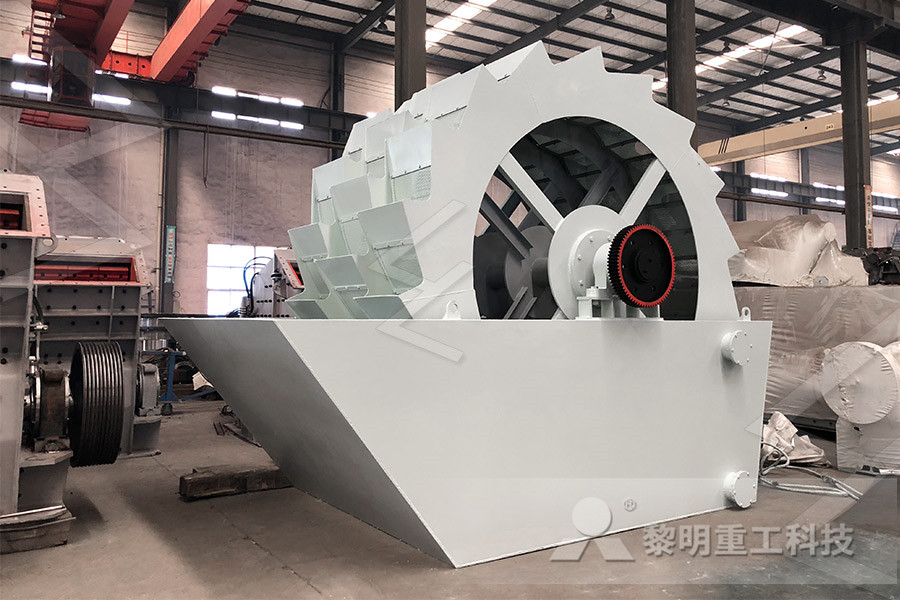

SAND, GRAVEL, AND CRUSHED STONE ONTHEJOB

crusher using pry bar, hammer and wedge, hydraulic hammer, grappling or crane hook, or dynamite POTENTIAL ACCIDENTS OR HAZARDS B) Detonation of explosives RECOMMENDED SAFE JOB PROCEDURES B) If dynamite or cap is observed in rock, do not try to remove it Shut off crusher and feeder, and call supervisor 5 A) Equipment starting 5Maxpower hydraulic hammer is produced under the quality assurance system, ISO9001, ISO14001, CE and GOST certification Maxpower hydraulic hammer is with antidust system, patented comfortable design, severe duty Hardox case on the bottom plate Maxpower hydraulic hammer is with underwater working application and autogreasing system as an optionHydraulic Breaker, Jack Hammer, Rock breaker tradekoreaPrinciple Operation Of A Coal Crusher Machine In Coal Power Plant Coal crushing machine and grinding mill for processing plant Learn More working of coal crushers,working of cone crusher video or bhu cone crusher working principle and parts Coal Cone Crushers Working Principle A cone crusher is an china,exported to algeria nigeria india Working Principle Operation Of A Coal Crusher Machine In Coal

Related Posts Hydraulic Breakers and Demolition

Sep 07, 2016 The LUBEMAXX hardened pump is operated by the hydraulic pressure from the hammer The unit simply installs to the breaker’s housing with a mounting plate and requires no separate electrical cables a leading provider of hydraulic breakers, compactors, crushers and pedestal booms for demanding patentpending locking wheel removal A pneumatic jackhammer, also known as a pneumatic drill or pneumatic hammer, is a jackhammer that uses compressed air as the power source The air supply usually comes from a portable air compressor driven by a diesel engine Reciprocating compressors were formerly used The unit comprised a reciprocating compressor driven, through a centrifugal clutch, by a diesel engineJackhammer WikipediaSep 02, 2019 The hydraulic systems on modern crusher designs eliminate the need for workers to place themselves in or under the crusher An overview of hydraulic system technology points to these three key elements: – A hydraulic chamberclearing system that automatically opens the crusher to a safe position, allowing materials to passPQ University Lesson 7 Crushing Secondary Breaking

Primary Crusher an overview ScienceDirect Topics

A design for a hammer crusher (Figure 26) allows essentially a decrease of the elevated pressure of air in the crusher discharging unit [5] The Azone beneath the screen is communicated through the hollow ribs and openings in the body side walls with the Bzone Sep 02, 2019 The hydraulic systems on modern crusher designs eliminate the need for workers to place themselves in or under the crusher An overview of hydraulic system technology points to these three key elements: – A hydraulic chamberclearing system that automatically opens the crusher to a safe position, allowing materials to passPQ University Lesson 7 Crushing Secondary Breaking Maintenance Procedure for hammer changing Removing the hammersrotor is at standstillopen the maintenance doorsmove the rotor with the rotor turning devicesecure the rotor in the desired positiondemount the cover of the hammer axisfix the hammer axis pulling device to the machineconnect the pull rod to the hammer axisfix the hammers in Hammer Crushers General Bearing (Mechanical

Stone Crusher Cone Jaw Crushers Machine Manufacturer

The safety and adjustment mode of hydraulic cone crusher is the same as that of hydraulic gyratory crusher Maintenance of cone crusher 1, Ensure full load production, avoid too coarse product granularity 2, Optimize the cone crusher productivity by setting reasonable crushing ratio 3, It is necessary that equipped with an iron removal deviceA pneumatic jackhammer, also known as a pneumatic drill or pneumatic hammer, is a jackhammer that uses compressed air as the power source The air supply usually comes from a portable air compressor driven by a diesel engine Reciprocating compressors were formerly used The unit comprised a reciprocating compressor driven, through a centrifugal clutch, by a diesel engineJackhammer WikipediaSep 07, 2016 The LUBEMAXX hardened pump is operated by the hydraulic pressure from the hammer The unit simply installs to the breaker’s housing with a mounting plate and requires no separate electrical cables a leading provider of hydraulic breakers, compactors, crushers and pedestal booms for demanding patentpending locking wheel removal Related Posts Hydraulic Breakers and Demolition

Hydraulic Breaker, Jack Hammer, Rock breaker tradekorea

Maxpower hydraulic hammer is produced under the quality assurance system, ISO9001, ISO14001, CE and GOST certification Maxpower hydraulic hammer is with antidust system, patented comfortable design, severe duty Hardox case on the bottom plate Maxpower hydraulic hammer is with underwater working application and autogreasing system as an option5) Install the funnel unit 6) Installing dust cover 7) Install the push cylinder according to the position, and connect its two interfaces to the interface of the hydraulic station 10 Feeding Device Installation 1) Incorrect installation will have the following effects on the cone crusher: a) The yield decreased; b)10 Steps To Install Cone Crusher MCMobile Crushers Innovation Advantages Our mobile crusher can be used in one stage of crushing for separate operation or complete joint operations with other crushing and screening portable plants to achieve twostage, threestage or fourstage crushing, so that various crusher screening requirements could be satisfiedMobile Crushers Mobile Crushing Plant

What are Hydraulic Accumulators? How do They Work

Jul 27, 2009 It is a simple hydraulic device which stores energy in the form of fluid pressure This stored pressure may be suddenly or intermittently released as per the requirement In the case of a hydraulic lift or hydraulic crane, a large amount of energy is required when the lift or crane is moving upward This energy is supplied from the hydraulic Description: Hydraulic Drum Elevators are devices designed to support one or more reels and they can be skid, trailer or truck mounted Tesmec Heavy Duty Drum Elevators are made of welded steel with a protective coating; the frames are detachable to reduce dimensions during transportHydraulic Lifting Device Products Suppliers (3)"Power Failure" Safety Device Effectively Responds To Overload When materials which cannot be crushed fall into the jaw crusher and a load of crushing machine exceeds the normal level, the elbow plate designed by Rhyther can realize automatic fracturing and then stop the jaw crusher, thus avoiding the damage of the entire machine and PE Jaw Crusher Rhyther Mining

Vertical Double Shaft Hammer Crusher In Indonesia

Double Shaft Hammer Crusher Method Of Hammer Removal Hazemag hammer crushers hds double shaft hammer crushers are mainly used in the cement industry for the turning and replacement of the hammers is facilitated by a hydraulic hammer bolt removal device together with a special lifting tool method of operation chat now More Details— Quick maintenance thanks to hydraulic hood opening and hammer pins extraction jack to easily remove wear parts APPLICATIONS FCB VIF™ Crusher is designed for primary and secondary applications Example for mediumhard limestone: — imary application, FCB VIF™ Crusher is fitted withIn pr an inertia flywheel and can accept over 1 m 3 FCB VIF™ Crusher