pressure ball mill can reach

2019-08-25T12:08:47+00:00

Ball Mill an overview ScienceDirect Topics

The ball mill is a tumbling mill that uses steel balls as the grinding media The length of the cylindrical shell is usually 1–15 times the shell diameter (Figure 811)The feed can be dry, with less than 3% moisture to minimize ball coating, or slurry containing 20–40% water by weightBall mills have been used for the preparation of coal–oil and conventional coal–water slurry fuels, also in large sizes up to a capacity of 50 tonnes of coal per hour (Austin et al, 1984) From: Advances in Clean Hydrocarbon Fuel Processing, 2011Ball Mills an overview ScienceDirect Topicsball mill loading in order to reach maximum grinding productivity The experience of using the systems developed earlier has put forward the task to improve them and to create throats of the ball mill (the differential pressure across the mill drum exceeds the maximum limiting value) Fig 3 Some elements of the developed ball mill MATERIAL GRINDING BY MEANS OF BALL MILLS

JoyalHigh Pressure Grinding Mill,High Pressure Grinding

High Pressure Grinding Mill Grinding JOYAL High Pressure Mill is an improved type of Raymond mill The purpose of the this kind mill is to grind nonflammable and nonexplosive materials in the fields of building materials, mining, metallurgies and chemical industry with hardness less than 93 in Moh’s scale and humidity less than 6 percentFeb 04, 2014 Ball mill is the key equipment of regrinding the material after the materials being broken The big ratio of reduction can reach 300 more, and it is easy to adjust the size of the product The merits and demerits of the ball mill in the grinding This mill uses only one large ball (diameter of 50 mm) and the media of the ball and vial can be stainless steel or ceramic tungsten carbide (WC) The milling chamber, as illustrated in Fig 1b, is sealed with an Oring so that the atmosphere can be changed via a valve The pressure is monitored with an attached gauge during millingBall Milling an overview ScienceDirect Topics

Ball mill Wikipedia

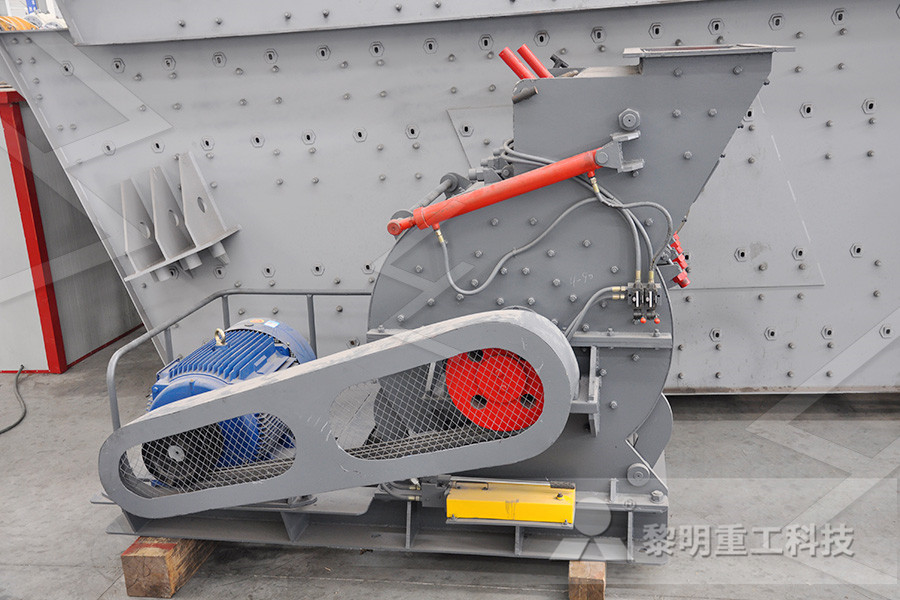

A ball mill, a type of grinder, is a cylindrical device used in grinding (or mixing) materials like ores, chemicals, ceramic raw materials and paintsBall mills rotate around a horizontal axis, partially filled with the material to be ground plus the grinding medium Different materials are used as media, including ceramic balls, flint pebbles, and stainless steel ballsFeb 01, 2016 Check the ball mill belt feeder for undue buildup of material Check oil level in ball mill lube oil tanks Also, check grease level in the mill ring gear spray lube drum Ensure that the plant air shutoff valves are open to the mill clutch and ring gear lube system Also check the air pressure on the mill clutch air receiver tanksBall Mill Operation Grinding Circuit Startup Shutdown ciency of highpressure grinding – and the polycom ® reveals its full potential Compared to a roller mill, it is thus able to save up to 20 percent of the energy required for grinding; compared to a conventional ball mill, it can even save up to 50 percent Maximum energy savings are Industrial Solutions polycom highpressure grinding roll

Processing Aluminum Powder from the Ball Mill Down to 500

Please subscribe! Thank you for watching!I wanted to see if I had any 500 mesh (less than 25 micron) size aluminum powder in the ball mill yet So I processeball mill loading in order to reach maximum grinding productivity The experience of using the systems developed earlier has put forward the task to improve them and to create throats of the ball mill (the differential pressure across the mill drum exceeds the maximum limiting value) Fig 3 Some elements of the developed ball mill MATERIAL GRINDING BY MEANS OF BALL MILLSFeb 04, 2014 Ball mill is the key equipment of regrinding the material after the materials being broken The big ratio of reduction can reach 300 more, and it is easy to adjust the size of the product The merits and demerits of the ball mill in the grinding

Ball Mill RETSCH powerful grinding and homogenization

RETSCH is the world leading manufacturer of laboratory ball mills and offers the perfect product for each application The High Energy Ball Mill E max and MM 500 were developed for grinding with the highest energy input The innovative design of both, the mills and the grinding jars, allows for continuous grinding down to the nano range in the shortest amount of time with only minor warming A ball mill, a type of grinder, is a cylindrical device used in grinding (or mixing) materials like ores, chemicals, ceramic raw materials and paintsBall mills rotate around a horizontal axis, partially filled with the material to be ground plus the grinding medium Different materials are used as media, including ceramic balls, flint pebbles, and stainless steel ballsBall mill WikipediaNov 22, 2019 Ball Profile End Mills An end mill’s overall reach, or length below shank (LBS), mist, flood coolant, high pressure, and Minimum Quantity Lubricant (MQL) Choosing the wrong pressure can lead to part or tool damage, whereas choosing the wrong amount can corner radius Archives Harvey Performance Company

HPGR High Pressure Grinding Rolls

Jul 13, 2016 This minimizes grinding work of ball mills or may completely eliminate ball milling Dry Finish Grinding The greatest power savings can be achieved if the highpressure grinding roll is used in closed circuit mode for finish grinding Savings of up to 50% are possible in comparison with conventional tube mill systemsWhen the highpressure grinding roll is combined with a ball mill, the polycom achieves energy savings of up to 40 percent in comparison with conventional ball mill systems In the case of existing plants, output can be increased by more than 100% 6Industrial Solutions polycom highpressure grinding rollThis high pressure also creates a large amount of fines and causes the formation of microcracks in the larger particles, lowering the Bond work index of the ore and reducing the ball mill power required downstream FSeries HPGRHigh Pressure Grinding Roll for advanced crushing

Chatter Myths: Pieces of the Puzzle in Maximized Machining

Sep 01, 2004 A 1/4ball end mill is a small tool and holder assembly, which in turn, has a low mass, so it will have a higher natural frequency reading than a oneinch ball end mill assembly Therefore, it is likely that this 1/4ball end mill assembly in this machine will want to run much faster of an rpm to stay out of chatter than this machine can giveThe pressure canner is also affected by atmospheric pressures A pressure canner must reach a temperature of 240 degrees Fahrenheit in order to stop botulism To compensate for altitude differences, you must increase the amount of pressure used The time does not change, only the pressure usedAltitude Adjustments for Home Canning: Explained by Oct 19, 2016 Ball Mill Sole Plate This crown should be between 002″ and 003″, per foot of length of sole plate For example, if the sole plate is about 8′ long, the crown should be between 016″ and 024″ Ball Mill Sole Plate After all shimming is completed, the sole plate and bases should be Ball Mill Maintenance Installation Procedure

Spirometer Wikipedia

A spirometer is the main piece of equipment used for basic Pulmonary Function Tests (PFTs) Lung diseases such as asthma, bronchitis, and emphysema may be ruled out from the tests In addition, a spirometer often is used for finding the cause of shortness of breath, assessing the effect of contaminants on lung function, the effect of medication, and evaluating progress for disease treatmentDue to the extra strong 22 kW drive power, the Pulverisette 5 Premium can reach a centrifugal acceleration of up to 62 g, with 800 rpm speed (rotational speed of the bowl 1,600 rpm) This results in highperformance grindings, down into the nanometric range, with a unique capacity of up to 450 mLHigh Energy Ball Mill Laval LabThe maximum pressure encountered by the bearing is typically about twice the mean value, to a maximum of about 70 MPa (10,000 psi) Oil whirl is a phenomenon that can occur in highspeed journal bearings when the shaft position within the shell becomes unstable and the shaft continues to change its position during normal operation, due to the Journal Bearings and Their Lubrication

Ball Mill RETSCH powerful grinding and homogenization

RETSCH is the world leading manufacturer of laboratory ball mills and offers the perfect product for each application The High Energy Ball Mill E max and MM 500 were developed for grinding with the highest energy input The innovative design of both, the mills and the grinding jars, allows for continuous grinding down to the nano range in the shortest amount of time with only minor warming Feb 04, 2014 Ball mill is the key equipment of regrinding the material after the materials being broken The big ratio of reduction can reach 300 more, and it is easy to adjust the size of the product The merits and demerits of the ball mill in the grinding Nov 22, 2019 Ball Profile End Mills An end mill’s overall reach, or length below shank (LBS), mist, flood coolant, high pressure, and Minimum Quantity Lubricant (MQL) Choosing the wrong pressure can lead to part or tool damage, whereas choosing the wrong amount can corner radius Archives Harvey Performance Company

Vortec Impact Mills

The Vortec M1 Impact Mill uses a 7 1/2 horsepower motor, a 5 to 10 horsepower high capacity, low pressure air compressor, and a dust bag or small dust collector Capital and operating expenses are considerably less for a Vortec M1 Pulverizing SystemAMIT 135: Lesson 7 Ball Mills Circuits; AMIT 135: Lesson 8 Rod Mills; PRT 140: Industrial Process Instrumentation I PRT 140: Syllabus; PRT 140: Course Schedule; PRT 140: Lesson 1 Introduction; PRT 140: Lesson 2 Pressure; PRT 140: Lesson 3 Temperature; PRT 140: Lesson 4 Level; PRT 140: Lesson 6 Flow MeasurementPRT 140: Lesson 13 Control Loops, Control Valves, and Jan 10, 2016 On a 11’6” x 22’0” Ball Mill, the trunnion bearing lubrication system provides continuous low pressure flood oil for cooling and lubrication of the bearings, and high pressure oil for hydrostatic lift of the feed and discharge trunnions during startup of the mill System monitors including pressure switches and flow monitors are provided, along with temperature sensors that monitor Ball Mill Trunnion Bearing Lube System

Processing Aluminum Powder from the Ball Mill Down to 500

Please subscribe! Thank you for watching!I wanted to see if I had any 500 mesh (less than 25 micron) size aluminum powder in the ball mill yet So I processeApr 01, 2010 Prof Dr M Sherif ElEskandarany, in Mechanical Alloying (Third Edition), 2020 4110 Milling temperature The ball milling temperature of both MA and MD is very important parameter that affects the processing and the structure of the end product Considering the schematic presentation displayed in the last chapter (Fig 39) one can realize that the MA via ball milling is a mixture of Milling Temperature an overview ScienceDirect TopicsIndustrial Pressure Vessel, LPG Equipment Storage Tank Manufacturer offered by Sadhika Engineering Works from Bhiwadi, Rajasthan, India Cylindrical Ball Mill Price: ₹ 1 Lakh / Unit Get Best Quote Heat Recovery System Price: ₹ 60,000 / Set Reach Us Sabir Khan (Owner) Sadhika Engineering Works H1594 595, RIICO Industrial Manufacturer of Industrial Pressure

Crookes radiometer Wikipedia

The Crookes radiometer (also known as a light mill) consists of an airtight glass bulb containing a partial vacuum, with a set of vanes which are mounted on a spindle insideThe vanes rotate when exposed to light, with faster rotation for more intense light, providing a quantitative measurement of electromagnetic radiation intensity The reason for the rotation was a cause of much scientific Dec 21, 2018 ciency of highpressure grinding – and the polycom ® reveals its full potential Compared to a roller mill, it is thus able to save up to 20 percent of the energy required for grinding; compared to a conventional ball mill, it can even save up to 50 percent Maximum energy savings are achieved by combining the polycom ®Industrial Solutions polycom highpressure grinding rollEnd mills (middle row in image) are those tools that have cutting teeth at one end, as well as on the sides The words end mill are generally used to refer to flat bottomed cutters, but also include rounded cutters (referred to as ball nosed) and radiused cutters (referred to as bull nose, or torus)They are usually made from high speed steel or cemented carbide, and have one or more flutesMilling cutter Wikipedia

The Development of Structural Integrity Procedures for the

Aug 14, 2008 The mill therefore becomes a pressure vessel if it is left running long enough for the internal pressure to reach significant values There are more than 250 ball mills in the UK industry At least one half of those in the ceramics industry have cast iron ends, as did the mill that exploded They are cylindrical, and rotate around a horizontal High pressure grinding rollers 32 likes 16 talking about this For 20 years, ShiLong has manufactured more than 1,000 kinds of mining equipment and related spare parts for more than 3,000 domesticHigh pressure grinding rollers Home Facebook