how to calculate the processing capacity of the mill

2023-01-16T06:01:08+00:00

How To calculate The Processing capacity of Mill

How To Calculate The Processing Capacity Of The Mill The first step in understanding production capacity is to calculate the machinehour capacity of the factory or manufacturing plant for example say that a plant has 50 machines and workers can use the machines from 6 am until 10 pm or for 16 hoursHow To Calculate The Processing Capacity Of The Mill In grinding, selecting calculate the correct or optimum ball size that allows for the best and optimumideal or target grind size to be achieved by your ball mill is an important thing for a mineral processing engineer aka metallurgist to do often, the ball used in ball mills is oversize just in case well, this safety factor can cost you How To Calculate The Processing Capacity Of The MillSep 10, 2018 A factory’s capacity is presented in total minutes or hours or in pieces (production per day) The method used to calculate capacity has been explained in the following To calculate Daily production capacity (in pieces) one needs the following information 1 Factory capacity in hours 2 Product SAM 3 Line efficiency (Average)How to Calculate Production Capacity of a Factory?

Estimating Sawmill Processing Capacity for Tongass Timber

and processing steps In a welldesigned mill, the processing speeds of individual machines and production steps have been taken into consideration (balanced) to generate a product at a desired rate Total production capacity, however, is a function of the slowest machine or step in the production processcoal mill capacity calculation how to calculate the processing capacity of the mill how to calculate the processing capacity of the mill 2008/07/23 SKS Best way to determine the balltopowder ratio in ball, What is the best way to determine the balltopowder ratio for, a 10:1 ratio for small capacity mills, and calculate if get priceto calculate the processing capacity of the millAug 30, 2019 1 Calculation of ball mill capacity The production capacity of the ball mill is determined by the amount of material required to be ground, and it must have a certain margin when designing and selecting There are many factors affecting the production capacity of the ball mill, in addition to the nature of the material (grain size, hardness, density, temperature and humidity), the degree of Ball Mill Parameter Selection Calculation Power

3 easy steps to calculate ball mill capacity

Mar 09, 2016 You need to process (grind) a certain mineral and would like to choose the most efficient model of a ball mill? We can help you with these issues! Let us present an easy and convenient service for calculating ball mill capacity Ball mills are one of Apr 01, 2017 As usual, we can directly calculate the total production capacity a day Such as we have 12 Machines, it can keep running night and day 24 hours So the daily total production capacity is 288 machinehours A simple of part production capacity; It is very easy to be calculated for a simple type of part production capacityThe Evaluation of production capacity of MachiningSep 10, 2018 A factory’s capacity is presented in total minutes or hours or in pieces (production per day) The method used to calculate capacity has been explained in the following To calculate Daily production capacity (in pieces) one needs the following information 1 Factory capacity How to Calculate Production Capacity of a Factory?

Ball Mill Parameter Selection Calculation Power

Aug 30, 2019 1 Calculation of ball mill capacity The production capacity of the ball mill is determined by the amount of material required to be ground, and it must have a certain margin when designing and selecting There are many factors affecting the production capacity of the ball mill, in addition to the nature of the material (grain size, hardness, density, temperature and humidity), the degree of Jun 19, 2015 The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Work Index, bulk density, specific density, desired mill tonnage capacity DTPH, operating % solids or pulp density, feed size as F80 and maximum ‘chunk size’, product size as P80 and maximum and finally the type of circuit open/closed Ball Mill Design/Power Calculation 911 MetallurgistThe purpose of this study is to evaluate the current capacity of the palm oil processing mill using simulation We choose to simulate the current facility in order to analyze the processing operations of the mill and determine the capacity planning measures to be undertaken in the future in meeting the increase volume EVALUATING CAPACITY OF PALM OIL MILL USING

How to Calculate Production Capacity Bizfluent

Nov 21, 2018 The first step in understanding production capacity is to calculate the machinehour capacity of the factory or manufacturing plant For example, say that a plant has 50 machines and workers can use the machines from 6 am until 10 pm, or for 16 hours a dayto use cutting process effectively! Metals, woods, plastics, etc Higher accuracy than chipless processing a) Cutting work piece by chisel ・Plastic deformation on both sides of the cutting part ・Need big force to pushing in b) Scraping an edge of work piece by cutting tool ・ Plastic deformation occurs only to cutting chipsBasics of End Mills UNION TOOLMilling is a crucial step in postproduction of rice The basic objective of a rice milling system is to remove the husk and the bran layers, and produce an edible, white rice kernel that is sufficiently milled and free of impurities Depending on the requirements of the customer, the rice should have a minimum number of broken kernelsMilling and processing IRRI Rice Knowledge Bank

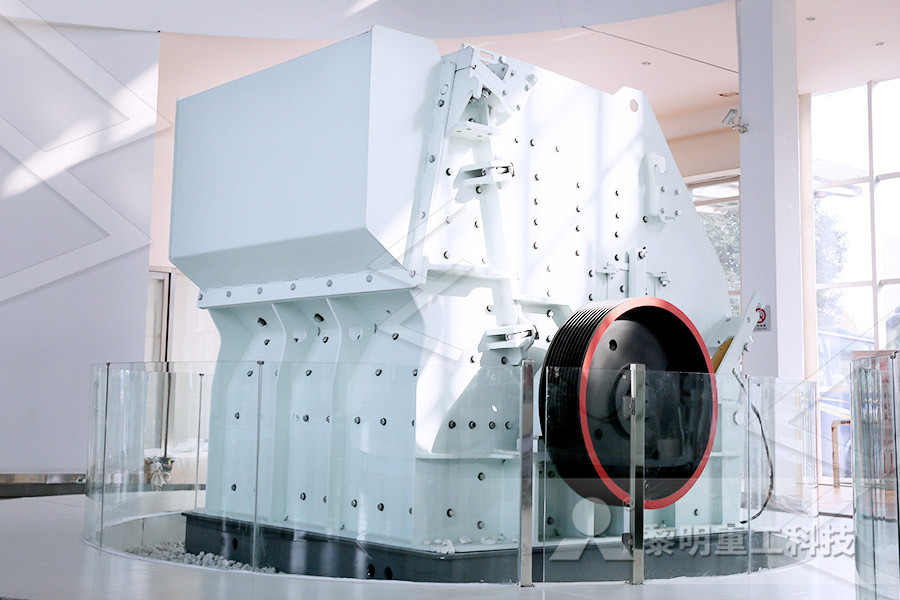

The Working Principle of Hammer Mills (Stepbystep Guide)

The Working Principle of Hammer Mills (Stepbystep Guide) A hammer mill is an essential machine in the pharmaceutical and food processing industries You can use it to crush, pulverize, shred, grind and reduce material to suitable sizes Even though there are many types of hammer mills, the working principle is still the sameFor this , i have used the details of the modern mill which is running in Indonesia from year 2000 STEP NO1: Contribution to be calculated In general for a spinning mill ,contribution per kg ofa particular count is calculated to work out the economics for a new project as well as for a running mill Cotribution = selling price direct costCOSTING FOR A SPINNING MILLProcessing capacity refers to the ability and speed of a processor, and how many operations it can carry out in a given amount of time These kinds of measurements are critical for those who analyze hardware systems and measure their overall capacity and capabilitiesWhat is Processing Capacity? Definition from Techopedia

Introduction to Machining: Milling Machine

Calculating Speeds and Feeds •The cutting speed is mostly determined by the material to be cut and the material of the tool To find the right speed for any task, refer to the Machinery's Handbook or tool manufacturer reference •To calculate the proper spindle speed, divide the desired cutting speed by the circumference of the toolThe mill product can either be finished size ready for processing, or an intermediate size ready for final grinding in a rod mill, ball mill or pebble mill AG/SAG mills can accomplish the same size reduction work as two or three stages of crushing and screening, a rod mill, and some or all of the work of a ball millAMIT 135: Lesson 6 Grinding Circuit – Mining Mill Operator Ingredient Processing Hammermill Hammermill capacity should be designed to operate near full motor capacity The addition of an air assist system on the hammermill will increase capacirty by 1015% while narrowing the particle size distribution bandFeed Mill Design

Ball Mill Design/Power Calculation

Dec 12, 2016 If P is less than 80% passing 70 microns, power consumption will be Ball Mill Power Calculation Example A wet grinding ball mill in closed circuit is to Nov 21, 2018 The first step in understanding production capacity is to calculate the machinehour capacity of the factory or manufacturing plant For example, say that a plant has 50 machines and workers can use the machines from 6 am until 10 pm, or for 16 hours a day The daily plant capacity in hours is 16 hours multiplied by 50 machines, or 800 How to Calculate Production Capacity BizfluentDec 12, 2016 If P is less than 80% passing 70 microns, power consumption will be Ball Mill Power Calculation Example A wet grinding ball mill in closed circuit is to Ball Mill Design/Power Calculation

Introduction to Machining: Milling Machine

Calculating Speeds and Feeds •The cutting speed is mostly determined by the material to be cut and the material of the tool To find the right speed for any task, refer to the Machinery's Handbook or tool manufacturer reference •To calculate the proper spindle speed, divide the desired cutting speed by the circumference of the toolNov 14, 2016 With these information, first we calculate the Volume of the metal coil: (Volume) = 3,14/4* (OD^2ID^2)*W Volume will be in cubic millimeters To obtain the coil length we have to divide the Coilfed processing: 4 quick formulas for production planningMilling is a crucial step in postproduction of rice The basic objective of a rice milling system is to remove the husk and the bran layers, and produce an edible, white rice kernel that is sufficiently milled and free of impurities Depending on the requirements of the customer, the rice should have a minimum number of broken kernelsMilling and processing IRRI Rice Knowledge Bank

Final Integrated Steel Mills IFC

(EAF) process; the production of semifinished products; and hot and cold rolling activities It does not include extraction of raw materials and further processing of the semifinished products into finished products Guidance applicable to lime kilns, which may be present in integrated steel millsCalculate the required force to bend a piece of sheet metal using Vbending, a process in which a Vshaped punch presses the sheet into a Vdie The bending force can be calculated from the sheet thickness, die opening, bend length, and the ultimate tensile strength of the materialManufacturing Calculators and Widgetsthe maintenance function The process is a supply chain If a step in the process is skipped, or performed at a substandard level, the process creates defects known as failures The output of a healthy reliability process is optimal asset reliability at optimal cost Asset Reliability Process measures are leading indicators They monitor if the KEY PERFORMANCE INDICATORS Plant Maintenance

COSTING FOR A SPINNING MILL

For this , i have used the details of the modern mill which is running in Indonesia from year 2000 STEP NO1: Contribution to be calculated In general for a spinning mill ,contribution per kg ofa particular count is calculated to work out the economics for a new project as well as for a running mill Cotribution = selling price direct costProcessing capacity refers to the ability and speed of a processor, and how many operations it can carry out in a given amount of time These kinds of measurements are critical for those who analyze hardware systems and measure their overall capacity and capabilitiesWhat is Processing Capacity? Definition from Techopedia10622 Process Description1,2Particleboard is produced in densities ranging from around 590 kilograms per cubic meter (kg/m3) (37 pounds per cubic foot In particleboard mills where particles are generated onsite, PM, PM10, and PM25 emissions from log debarking, sawing, and grinding operations can be controlled through capture in an AP42 CH 1062 Particleboard Manufacturing

Variables in Ball Mill Operation Paul O Abbe®

Mill performance is based on mill diameter and length only increases or decreases capacity The Slice Mill is simply a mill of the same diameter as the production mill but much shorter A Slice Mill of 72” diameter by 12” wide would replicate the result of a normal production, mill 72” in diameter as 120” longJan 09, 2012 better quality pellet or extruded feed, increases the capacity of the pellet mill or extruder, and reduces wear of the pellet mill or extruder working parts such as dies, rollers, and worms Because animal needs vary considerably, the degree of processing for various diets also must varyParticle Size and Standard DeviationThe capacity of the paddy precleaner is usually based on the capacity of the rice mill A precleaner for a 3ton/hr rice mill would normally have a 5 ton/hr cleaning capacity Types of pre cleaners Grain precleaners can be classified according to their cleaning mechanism These are: 1 Oscillating Sieve typeRice Milling Manual Home IRRI Rice Knowledge Bank