designing of a vat leaching plant for gold processing

2021-12-03T09:12:35+00:00

(DOC) VAT LEACHING AND ELUTION PLANT GOLD PROCESSING

Introduction of VatLeachingVat leaching has been around since Roman times, but had become viable in 1896, when cyanide leaching began in earnest with the MerrillCrowe ProcessIn an article in the Engineering and Mining Journal in December 1999, Lou Cope described the first vat leaching at Homes take in 1901, which later improved the process in 1906 by adding a desliming circuitJul 13, 2016 Cyanidation and concentration of gold and silver ores Vat Leaching Copper Ore Vat leaching is a simple and efficient mode of effecting adequate contact between the solute and aqueous solvent It utilizes the countercurrent principle, with the ore to be leached remaining stationary, as differentiated from most countercurrent methods, where Vat Leaching of Finely Crushed Gold Ore 911 MetallurgistDesigning Vat Leaching Plant For Gold Processing used a low capital expenditure vat leach process to recover gold from ores having good gold liberation at a p80 greater than 300 microns CSIRO said In under 10 months the demonstration project took a laboratory developed concept and transformed it into a demonstration plant involving designDesigning Vat Leaching Plant For Gold Processing

Gold Vat Leaching 911 Metallurgist

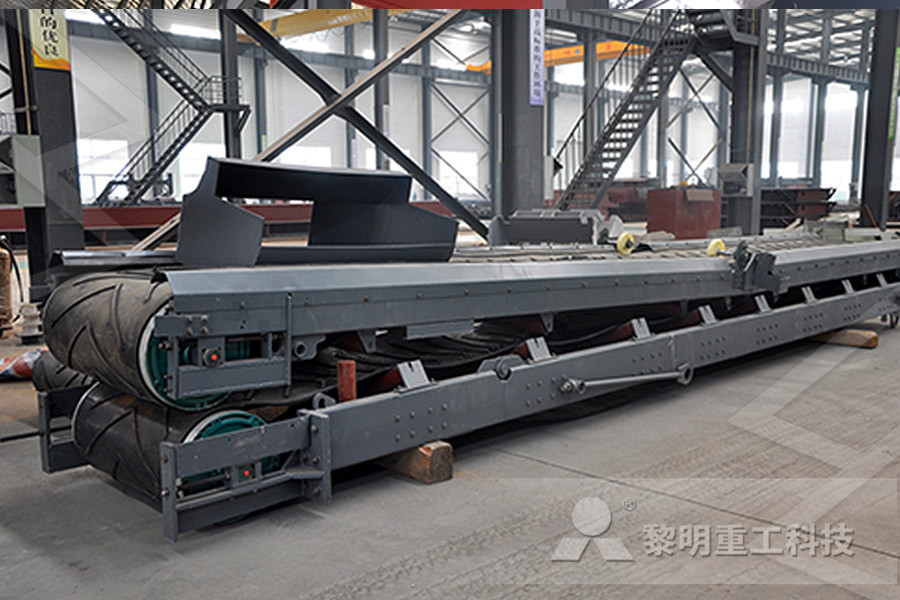

Nov 02, 2016 Gold Vat Leaching Wooden vats are made of staves, 4 to 6 inches wide and 3 inches or more thick, held together by round iron hoops, with bottom planks 3 inches thick, fitting into a slot in the stavesMay 13, 2013 The latest development in vat leaching is a continuous unit, invented by Dan Mackie of Innovat Ltd, called an Ecovat Feed to the rectangular tank is via a slurry stream or dry ore by conveyor If dry ore is fed, it is slurried by solution injected in the bottom of the vatDay 51, Procedures to obtain gold: Vat Leaching Process that should be considered during the design of leach and CIP/CIL circuits in order to ensure that these objectives are met In addition, simulation and modelling techniques that can assist with this design process are also described Figure 1 provides an illustration of the generic process used to design a chemical or metallurgical plantThe process design of gold leaching and carboninpulp

designing of a vat leaching plant for gold processing

1333 Results Gold Leaching Plant/Gold Processing Plant US $10005000 / Set ( FOB Tank Mixing Agitator/ Copper Leaching Plant for Sale US $12009000 / Set Professional design gold ore mining plant with cyanide leaching process Read moreAug 01, 2017 1 Introduction The governing method for gold ore processing has been cyanide leaching since the late 19th century (Marsden and House, 2006)After decades of active development of the process for various types of ores and concentrates, there are several different hydrometallurgical flowsheets for cyanide leachingDesigning gold extraction processes: Performance study of After the leaching process is complete, the soluble gold must be concentrated and separated from the process slurry The method of recovery of gold from the process slurry is by carbon adsorption Adsorption is a term used to describe the attraction of a mineral Leaching Adsorption Resource Book WordPress

(PDF) Online Optimization of a Gold Extraction Process

Jun 29, 2017 However, the leaching plant is usually designed as a series of agitated tanks of the same size, without any attempt to find an optimal plant design for improving the circuit efficiency, either by Jul 29, 2013 The Vat Leaching Process Vat leaching can be described as leaching in a bathtub inside a building Treatment of ore is sitespecific as determined by metallurgical tests Bench scale metallurgical testing of ores for their amenability to vat leaching is similar to that for heap leachingDay 51, Procedures to obtain gold: Vat Leaching Process Feb 18, 2019 GOLD VAT LEACHING CONSTRUCTION Tank and vat leaching involves placing ore, usually after size reduction and classification, into large tanks or vats at ambient operating conditions containing a leaching solution and allowing the valuable material to leach from the ore into solution Cyanide tank construction Cyanide tanks are the main facilities for tank leaching process, which are WHY INVESTING IN TANZANIA GOLD VAT LEACHING PROCESS PLANT

4 Factors Affecting Gold VAT Leaching Process

Jun 05, 2020 Gold vat leaching process is currently widely used in smallscale gold mines, because of a series of advantages including high recovery rate, strong adaptability to ore, low cost and simple process The basic principle is first to leach the gold from the ore with cyanide solution containing oxygen, and then to extract the gold from the leaching solution with zinc powder or zinc wirePrecious Metal Heap Leach Design and Practice Daniel W Kappes1 ABSTRACT Heap leaching of gold and silver ores is conducted at approximately 120 mines worldwide Heap leaching is one of several alternative process methods for treating precious metal ores, and is selected primarily to take advantage of its low capital cost relative to other methodsPrecious Metal Heap Leach Design and PracticeOther articles where Vat leaching is discussed: gold processing: Cyanidation: ore), cyanidation is accomplished by vat leaching, which involves holding a slurry of ore and solvent for several hours in large tanks equipped with agitators For extracting gold from lowgrade ores, heap leaching is practiced The huge heaps described above are sprayed with a dilute solution of sodium cyanide Vat leaching industrial process Britannica

Designing gold extraction processes: Performance study of

Aug 01, 2017 1 Introduction The governing method for gold ore processing has been cyanide leaching since the late 19th century (Marsden and House, 2006)After decades of active development of the process for various types of ores and concentrates, there are several different hydrometallurgical flowsheets for cyanide leachingThiosulphate leaching is a process that removes gold from gold bearing ores without the use of cyanide Although not spent years designing and developing the technique into a viable alternative to back to the leach plant to minimize thiosulphate losses and new thiosulphate make up requirements, or use the tailings THIOSULPHATE LEACHING – AN ALTERNATIVE TO CVL is a mechanical leaching system developed by Innovat Mineral Processing Solutions The basic concept is to provide, by means of an elevated head tank, intermittent fluidisation of the ore in a swimming poollike vatContinuous Vat Leaching (CVL) Glycine Leaching

Leaching Adsorption Resource Book WordPress

After the leaching process is complete, the soluble gold must be concentrated and separated from the process slurry The method of recovery of gold from the process slurry is by carbon adsorption Adsorption is a term used to describe the attraction of a mineral performance of gold plants, and optimize CIP or CIL plant design, is to conduct inexpensive bench scale metallurgical tests to exam ine the rheological properties of a leach pulp early in the (PDF) Factors influencing the rate of gold cyanide Gold ore Prominer maintains a team of senior gold processing engineers with expertise and global experience These gold professionals are specifically in gold processing through various beneficiation technologies, for gold ore of different characteristics, such as flotation, cyanide leaching, gravity separation, etc, to achieve the processing plant of optimal and costefficient process designsGold Processing,Extraction,Smelting Plant Design

Document: TECHNICAL MEMORANDUM Project: INNOVAT

The mining and material handling process has been unmodified for the 10,000t/d Continuous Vat Leach case, and modified only as a result of the reduction in processing rate for the 5,000t/d CVL case The crushing circuit has been modified as a result of the Continuous Vat Leaching process feed size requirement of 6mmOct 01, 2018 Cyanide is used in more than 90% of global gold production, but producers are facing increasingly tough regulations restricting the use of cyanide due to environmental and health concerns The CSIRO technology replaces cyanide with thiosulfate, a nontoxic, mobileplant alternative It is a simple vatandheapleach process involving low capital Extracting gold without cyanide Chemical Engineering free circulation of the leaching agent The leaching period is 2 – 4 days and gold recovery lies in the order of 70 – 80% The cheapest but slowest technique is heap leaching It is a process usually applied to low grade gold ore Basically the ore is piled to a given height on an inclined impermeable surface, a so called leach padsketches tables UNIGE

4 Factors Affecting Gold VAT Leaching Process

Jun 05, 2020 Gold vat leaching process is currently widely used in smallscale gold mines, because of a series of advantages including high recovery rate, strong adaptability to ore, low cost and simple process The basic principle is first to leach the gold from the ore with cyanide solution containing oxygen, and then to extract the gold from the leaching solution with zinc powder or zinc wireFeb 18, 2019 GOLD VAT LEACHING CONSTRUCTION Tank and vat leaching involves placing ore, usually after size reduction and classification, into large tanks or vats at ambient operating conditions containing a leaching solution and allowing the valuable material to leach from the ore into solution Cyanide tank construction Cyanide tanks are the main facilities for tank leaching process, which are WHY INVESTING IN TANZANIA GOLD VAT LEACHING PROCESS PLANT Other articles where Vat leaching is discussed: gold processing: Cyanidation: ore), cyanidation is accomplished by vat leaching, which involves holding a slurry of ore and solvent for several hours in large tanks equipped with agitators For extracting gold from lowgrade ores, heap leaching is practiced The huge heaps described above are sprayed with a dilute solution of sodium cyanide Vat leaching industrial process Britannica

vat leaching you tube

(DOC) VAT LEACHING AND ELUTION PLANT GOLD PROCESSING Introduction of VatLeachingVat leaching has been around since Roman times, but had become viable in 1896, when cyanide leaching began in earnest with the MerrillCrowe ProcessIn an article in the Engineering and Mining Journal in December 1999, Lou Cope described the first vat leaching at Homes take in 1901, which later The Leachox™ Refractory Gold Process – The Testing, Design, Installation and Commissioning of a Large Scale Plant at the VASGOLD Gold Mine, Kazakhstan Stephen Flatman ¹, Michael Battersby 1, Rainer Imhof ¹, Richard Mark Battersby ¹ and Sabit Ibrayev 1 Maelgwyn Mineral Services Ltd, Ty Maelgwyn House , 1A Gower Street, Cathays, Cardiff,The Leachox™ Refractory Gold Process – The Testing, Design The mining and material handling process has been unmodified for the 10,000t/d Continuous Vat Leach case, and modified only as a result of the reduction in processing rate for the 5,000t/d CVL case The crushing circuit has been modified as a result of the Continuous Vat Leaching process feed size requirement of 6mmDocument: TECHNICAL MEMORANDUM Project: INNOVAT

How to set up an ecofriendly gold processing plant

Nov 07, 2019 However, if miners choose to include Clean Mining’s dewatering process option in their plant design, both the chemicals and water reclaimed from the leach tailings are recyclable With an estimated moisture content of between 8% to 15% in most dry stack leach tailings, that provides great potential for both thiosulphate compound and water chamber block, and a store and pit latrine On processing section, the plant is designed to comprise of nine leach tanks, carbon chamber inside the laboratory block, underground mixing tank/barren tank, water reservoir tank and overhead raised water tanks that feeds leach tanks There is Environmental Impact Assessment Project ReportCyanide leaching now recovers the greatest amount of gold and contributes to a variety of flowsheets from heap leaching to agitated leaching circuits Newly discovered deposits are often more refractory and resist these methods Ores in which gold is locked with sulfides are processed by combining flotation with other methodsDesigning Gold Project Flowsheets SRK Consulting

(PDF) Factors influencing the rate of gold cyanide

performance of gold plants, and optimize CIP or CIL plant design, is to conduct inexpensive bench scale metallurgical tests to exam ine the rheological properties of a leach pulp early in the plant setup on the Menzies Battery site in Western Australia uses a low capex vat leach process to recover gold from ores having good gold liberation at a p80 greater than 300 micron In under 10 months the demonstration project has taken a laboratory developed concept and transformed it into a demonstration plant involving design, build and ALTA MetBytes What's Happening in Gold Ore ProcessingCIL gold processing plant mainly consists of following steps: 1 The ore is first reduced in size (typically 90% passing 200mesh ) to ensure that all nonrefractory gold is readily accessible for cyanide leaching, There are several variations of comminution circuits used in the gold leaching industry, such as: Multistage crushing, then ball milling circuits, typical of ball mill and hyrocyclonesCIL gold processing plant CIL processing plant for sale

Metallurgical testwork: Gold processing options, physical

Jan 01, 2005 1 Background For the past 100 years the key element in the processing of gold ore has been the cyanidation process Over the years steady improvements have occurred in equipment design; milling has evolved from stamp mills, through tube mills and ball mills to the large semiautogenous grinding (SAG) and fullyautogenous grinding (FAG) circuits in modern gold plantsJan 12, 2021 The Curtin process requires none of these Coresearch lead and chair for extractive metallurgy for the Future Battery Industries Cooperative Research Centre Jacques Eksteen said the technology used a low concentration of the strong oxidising agent potassium permanganate, which produced better results compared with other oxidants for the alkaline glycine gold leach systemResearchers find cyanidefree gold leaching process