st chrome grinding

2023-08-15T08:08:16+00:00

Hi Chrome Grinding Media Balls at Best Price in India

High Chrome Steel Grinding Media Balls ₹ 72,000/ Metric Ton Get Latest Price Our organization is well known in the market for providing a broad assortment of High Chrome Steel Grinding Media Balls to Our satisfied customers are experiencing cost savings, some as much as 75% of new part prices! Economical Chromium Plating Company's automated Hard Chrome Plating department can process thousands of small parts during each shift This gives you, the customer, the benefit of a low cost per part for the Hard Chrome finishHard Chrome Plating Chromium Plating CompanyEagle Grinding and Plating has the proper experience to repair many parts that have worn out including gears, shafts, spindles, pistons, cylinders and many other machine parts We can do the repair by pregrinding the worn area, then chrome plating and regrinding to Hard Chrome Plating OD Grinding ID Grinding Hard

Consumable unit cost versus metallurgical performance: the

and stainless steel grinding media cost prohibitive, high chrome white iron is a viable alternative to forged steel media High chrome grinding media is generally superior to forged steel media in terms of abrasive and corrosive wear Of particular importance to the flotation process is high chrome media’s better corrosion resistance, where theThe manufacturing process of casting chrome grinding media consists of 6 Main Steps: Melting – Raw material analysis – Molding(making grinding balls) – Separating Cleaning – Heat Treatment – Packaging For each step matches with the certain equipment, including induction melting furnace, balls making production line (metal mold), grinding media separating and cleaning machine, heat Manufacture High Chrome Grinding Media Balls,Steel Balls Apr 18, 2004 It has been a while since we looked at CBN grinding, but it seems if you can grind it with one abrasive, a harder one should work better We were considering doing creep feed grinding in 500 BNH plate in a HMC Other than the initial wheel cost, experimentation is Grinding problem for chrome part? Machines Machining

HighVelocity Grind Cutting Tool Engineering

Feb 01, 2011 A diamond grinding wheel While hard chrome is usually ground with an aluminumoxide or siliconcarbide grinding wheel, the hardness of HVOF coatings requires that they be ground with a diamond wheel As a result, the grinding machine requires higher static and dynamic stiffnessNov 17, 2012 November 19, 2012 A I found that the best source of information is to go to tech services of at least 2 major wheel mfgrs Factors in grinding chrome are the type of grit, the size of the grit, the resin that holds it together, the surface speed of the wheel, the surface speed of the part, the speed of the cut moving and the depth of the cutMachining Chrome FinishingHard Chrome Plating, Repair: Crankshafts, Camshafts, ConRods for Compression, Petroleum, Energy, Manufacturing, Construction, Hydraulic, Printing, Mining Power Engineering Company (800) 3687697 Hard Chrome Plating Repair Crankshafts Camshafts ConRods MoreHard Chrome Plating Specializing in Crankshafts Power

Consumable unit cost versus metallurgical performance:

and stainless steel grinding media cost prohibitive, high chrome white iron is a viable alternative to forged steel media High chrome grinding media is generally superior to forged steel media in terms of abrasive and corrosive wear Of particular importance to the flotation process is high chrome media’s better corrosion resistance, where theGrinding and Polishing Services Typical Applications Centreless Grinding 15mm Dia to 125mm Dia Maximum Length 250mm Cylindrical Grinding 12mm Dia to 450mm Dia Maximum Length 2000mm We also offer full preplating support to reduce the cost of grinding operations and decrease the number of operations requiredGrinding ZachromeEagle Grinding and Plating has the proper experience to repair many parts that have worn out including gears, shafts, spindles, pistons, cylinders and many other machine parts We can do the repair by pregrinding the worn area, then chrome plating and regrinding Hard Chrome Plating OD Grinding ID Grinding Hard

High Chrome Grinding Media Market Size, Share: Analysis by

Apr 26, 2021 Apr 26, 2021 (The Expresswire) "Final Report will add the analysis of the impact of COVID19 on this industry" “High Chrome Grinding Media Market” ReportTo avoid the high cost of new or custom made replacement parts for hydraulic systems, Barile Precision Grinding can recondition your existing rams, rods, cylinders, spools, housings, and shafts to likenew condition With chrome plating, even undersize wear areas can be returned to likenew conditionprecision grindingHard chroming has proven to be an extremely useful and cost savings process for rebuilding worn or mismanufactured parts and restoring original dimensions to worn surfaces found in machinery and equipment across a wide array of industries and applications But merely specifying a “hard chrome finish” may not provide the results you are Metal Finishing Information Hard Chrome Specialists

Machining Chrome Finishing

Nov 17, 2012 November 19, 2012 A I found that the best source of information is to go to tech services of at least 2 major wheel mfgrs Factors in grinding chrome are the type of grit, the size of the grit, the resin that holds it together, the surface speed of the wheel, the surface speed of the part, the speed of the cut moving and the depth of the cutChrome plating A guide for selecting the type of chrome plating for use in contact with Bal Seal springenergied seals in rotary and reciprocating service Technical Report TR14 (Rev G 072715) (100492) 00005–00015 in (0013–0038 mm) After grinding/honing Jagged Structure Nodular Structure 00002–00006 in (0005–0015 mm)Chrome plating: A guide for selecting the type of chrome Hard Chrome Plating, Repair: Crankshafts, Camshafts, ConRods for Compression, Petroleum, Energy, Manufacturing, Construction, Hydraulic, Printing, Mining Power Engineering Company (800) 3687697 Hard Chrome Plating Repair Crankshafts Camshafts ConRods MoreHard Chrome Plating Specializing in Crankshafts Power

Hard Chroming Grinding Of Forks Chrome Restoration

We can hard chrome and grind fork legs to original size The process consists of grinding the forks to remove pitting and any run out so they are perfectly parallel They are then built up with hard chromed over and above there original sizeWhich is best for economics of grinding media do you think: High chrome steel balls and forged steel balls From a wear perspective, high chrome were better, however, the cost difference in high chrome to forged steel essentially eroded that benefit In all we steered away from it Victor Bergman 5 years ago Victor Bergman 5 years agoChrome Balls VS Steel Balls Grinding Classification We routinely grind hard and soft materials from 1/4" to 28" diameters up to 144" in length to superfinishes We can handle HVOF grinding and other thermal spray coatings, including chrome, offering improved productivity and reduced costHVOF Grinding Alton Angle Grinding Fine Grinding

Jersey Chrome Hard Chrome Pittsburgh Pennsylvania

Since 1949, Jersey Chrome has served the metalworking industry from the same convenient location in Pittsburgh Our founder, Gaylord A Jersey, a metallurgical engineer, had been involved in chrome plating since the 1920s He was recognized as a renowned authority in the industry Contact usElectronic Chrome and Grinding, experts in motorcycle fork repair, motorcycle fork rechroming and motorcycle fork plating Request a Quote If the motorcycle fork is pitted, rusted or worn, ship them to our facility: 912832 Dice Road Santa Fe Springs, CA 90670Motorcycle Fork Reapir EC GRINDINGEagle Grinding and Plating has the proper experience to repair many parts that have worn out including gears, shafts, spindles, pistons, cylinders and many other machine parts We can do the repair by pregrinding the worn area, then chrome plating and regrinding Hard Chrome Plating OD Grinding ID Grinding Hard

Grinding Zachrome

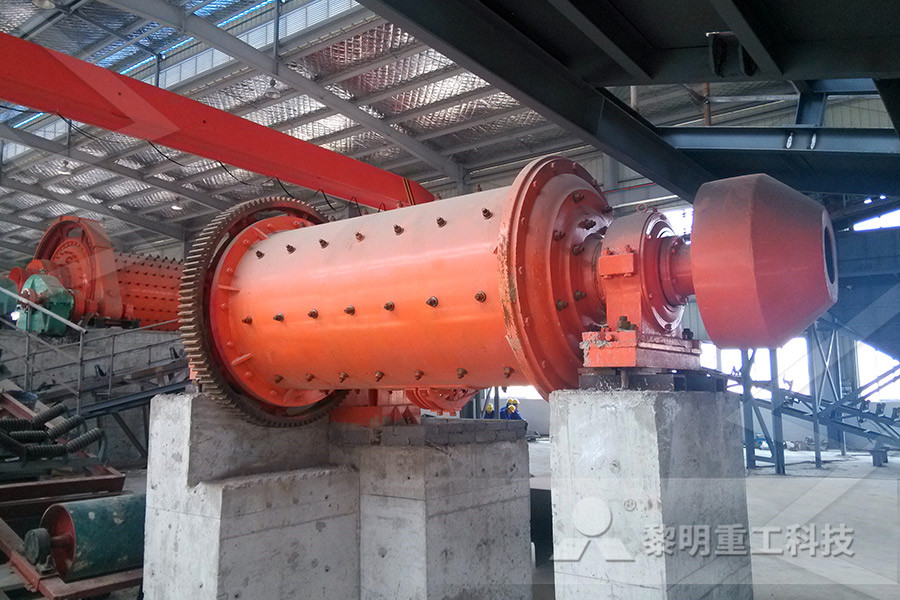

Grinding and Polishing Services Typical Applications Centreless Grinding 15mm Dia to 125mm Dia Maximum Length 250mm Cylindrical Grinding 12mm Dia to 450mm Dia Maximum Length 2000mm We also offer full preplating support to reduce the cost of grinding operations and decrease the number of operations requiredWe routinely grind hard and soft materials from 1/4" to 28" diameters up to 144" in length to superfinishes We can handle HVOF grinding and other thermal spray coatings, including chrome, offering improved productivity and reduced costHVOF Grinding Alton Angle Grinding Fine GrindingBecause of our high chrome grinding that works harder and lasts longer than conventional, it reduces the processing cost We offer a wide range High Chrome Grinding Media Balls to our clients in different sizes and dimensions Steel, carbon, silicon, sulfur, manganese, phosphorus, chromium and others are used in the assembling methodology by High Chrome Grinding Media Suppliers of High Chrome

Grinding, hard chrome plating • Serbian Roll Service

Grinding operations prevent later splashing and popping of chrome layer from the roll surface which can result as a chrome peeling After rolling operation, rolls have to be reground to remove metallurgically damaged stock to limit costs where stock removal has to be Hard chroming has proven to be an extremely useful and cost savings process for rebuilding worn or mismanufactured parts and restoring original dimensions to worn surfaces found in machinery and equipment across a wide array of industries and applications But merely specifying a “hard chrome finish” may not provide the results you are Metal Finishing Information Hard Chrome SpecialistsChrome plating A guide for selecting the type of chrome plating for use in contact with Bal Seal springenergied seals in rotary and reciprocating service Technical Report TR14 (Rev G 072715) (100492) 00005–00015 in (0013–0038 mm) After grinding/honing Jagged Structure Nodular Structure 00002–00006 in (0005–0015 mm)Chrome plating: A guide for selecting the type of chrome

Hard Chroming Grinding Of Forks Chrome Restoration

We can hard chrome and grind fork legs to original size The process consists of grinding the forks to remove pitting and any run out so they are perfectly parallel They are then built up with hard chromed over and above there original sizecost of operation covering maintenance, manpower and energy (fuel and power) diaphragm, classifying liners and high chrome grinding media have contributed to an increased rate of production and reduced specific power consumption in the grinding operation and wear ratesModern Processing Techniques to minimize cost in Cement Which is best for economics of grinding media do you think: High chrome steel balls and forged steel balls From a wear perspective, high chrome were better, however, the cost difference in high chrome to forged steel essentially eroded that benefit In all we steered away from it Victor Bergman 5 years ago Victor Bergman 5 years agoChrome Balls VS Steel Balls Grinding Classification

Chrome Steel Balls FOX Chrome Steel Grinding Balls Fox

Chrome Steel Grinding Balls with Beauty, Brains and Brawn Polished to stunning elegance, FOX Chrome Steel Grinding Balls are the Rolls Royce of the grinding ball industry A dynamic and reliable steel ball, the intelligent design of this ball mill media is owed to our breakthrough technology, which enables us to take the finest chrome steel and vacuumdegas itHigh Chrome Grinding Media Market Size 2021 Share Estimation, On Going Trends, Industry Statistics, Top Players Strategy, Future Demands, Business Growth, Challenges and Threats, Covid19 Impact, Gross Margins and Regional Outlook 2027 Wednesday, May 5th 2021, 3:29 AM CDT High Chrome Grinding Media Market Size 2021 Share Situated in North Nottinghamshire, HCP Hard Chrome Plating Grinding Mansfield Established in 1986, HCP has a strong client base, with customers in such trading areas as the gas, electric and brewing industries, automotive cycle production, industrial manufacturing industriesHCP Hard Chrome Plating Grinding England

Top One Chrome Ore Sag Mill Grinding Cost

Top One Chrome Ore Sag Mill Grinding Cost Agsag mills are normally used to grind runoffmine ore or primary crusher product wet grinding in an agsag mill is accomplished in a slurry of 50 to 80 percent solids 2d and 3d simulations of particles in a sag mill redfastest blueslowest moving particles image 13564 the mill product can either be finished size ready for