wear and tear in al mill in cement industries

2020-12-19T12:12:35+00:00

wear and tear in coal mill in cement industries pdf

wear and tear in coal mill in cement industries pdf ERODUR 801 wear plate provides excellent resistance to severe erosion and moderate impact The alloy primarily consists of carbides, borides and other complex carbidesFeb 21, 2013 Grinding elements take the wear and tear of coal pulverisation 21st February 2013 Paul Boughton For more than 10 years Xwin technology from Magotteaux has been applied to numerous vertical roller mill (VRM) applications throughout the world in aggregate, cement, mining and powerGrinding elements take the wear and tear of coal wear protection in vertical roller mills Mining amp Quarry Less wear and tear Vertical roller mills for grinding cement raw meal and coal are the standard Vertical roller mills are used in the cement industry wear and tear in coal mill in cement industries : pdf

Cement Cement Mill Wear Tear Area And Solution

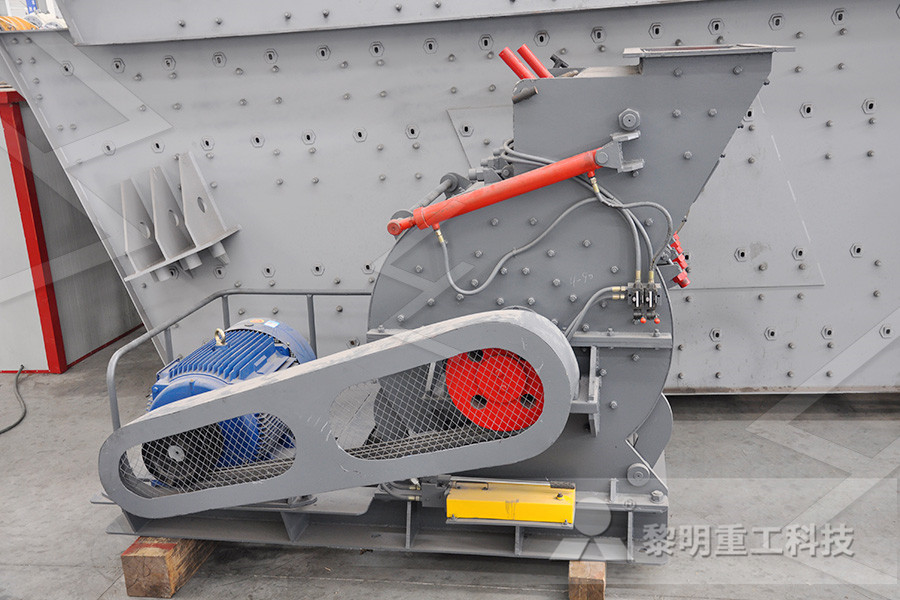

Cement Cement Mill Wear Tear Area And Solution Ball Mill Ball mill machine is widely applied in the industries such as cement silicate product refractory fertilier mineral processing of ferrous and nonferrous metal and glass ceramic etc It is mainly used to make dry or wet powder grinding of various ores and other grindable materials Apr 12, 2021 Widely used in coal conveying, pulverizing, ash discharge systems for thermal power generation, and material conveying and batching systems in metallurgy, iron and steel, cement and other industries Such as coal mill outlet pipe, coarse and fine powder separator inlet pipe, primary air duct elbow, pulverized coal pipe, dust removal pipe, ash Wearresistant ceramic elbow solves difficult problems Cement manufacturing involves wear and tear of many equipment parts due to abrasion, mainly from quartz and illite contamination of the limestone By selecting just the right wear material for every stage in the cement production chain, we can help you to maximize uptime and minimize maintenance from the limestone quarry to the moment the Cement production and wearresistant solutions Hardox

Coal Mill Safety

Improving coal mill safety in the cement sector is a continuous and varied challenge I hope that by highlighting some of the most common problems and failings in these pages – in terms of systems, attitudes and regulations – I can make others aware of how they can influence this area for the betterCoal in the cement industry Cement manufacturing consists of raw meal grinding, blending, pre calcining, clinker burning and cement grinding Limestone, CaO, SiO2, Al2O3 and Fe2O3 are crushed and milled into a raw meal This is blended and preheated in a preheater cycloneCoal in the cement industryCoal Mills for Cement Plants Coal grinding mills LOESCHE coal grinding mills are distinguished by characteristics that improve efficiency, safety and environmental protection, from the standard version to topoftherange installationsCoal Mills for Cement Plants Loesche

Cement Cement Mill Wear Tear Area And Solution

Cement Cement Mill Wear Tear Area And Solution Ball Mill Ball mill machine is widely applied in the industries such as cement silicate product refractory fertilier mineral processing of ferrous and nonferrous metal and glass ceramic etc It is mainly used to make dry or wet powder grinding of various ores and other grindable materials Cement manufacturing involves wear and tear of many equipment parts due to abrasion, mainly from quartz and illite contamination of the limestone By selecting just the right wear material for every stage in the cement production chain, we can help you to maximize uptime and minimize maintenance from the limestone quarry to the moment the Cement production and wearresistant solutions Hardox Although the company’s origin is on plants for the cement industry, the mills and systems are also used in the power station industry, ore processing, industrial minerals and in coal grinding Up to 90 % of the mechanical engineering company’s output goes to the export market The degree of wear and tear depends on many factors, making Efficient processes for grinding and separation Cement

Dampers for the Cement Industry • Kelair Dampers

The harsh conditions of cement production result in rapid wear and tear on equipment Kelair’s premium dampers are able to withstand this environment with durable materials resulting in less repair and maintenance over time These industrial dampers provide precision and efficiency to help suppliers and manufacturers in the cement industry Challenges in the cement and minerals industries The cement and minerals industries are characterized by KMPS gear units are used for coal mills in the medium power range, combining a bevel gear stage with a helical normal wear and tear, by stocking parts on site Thus, depending on the package and type of breakdown, the Spare part packages for mechanical drive technologyThese components are repaired/ reclaimed and reused in industry to achieve 100200% performance at negligible cost as compared to the cost of original components Duraweld Offers Reclamation Services For 1 Coal Mill / Raw Mill Grinding Rolls, Table Liners in Cement Mining Industries 2 High Pressure Roller Press Roll in Cement Industries 3Duraweld Metsys Pvt Ltd

Deccan Mechanical and Chemical Industries

In power, steel, aluminium, and cement sectors, abrasive materials are pneumatically or hydraulically conveyed through pipelines resulting in heavy wear and tear This necessitates the use of a protective liner to prevent wear and enhance the life of equipment4) High wear and Tear resistance properties We offer wide range Chevron Belt Belts for Cement plant for the applications like quarry, mining etc We offer Steel Cord Belts for Cement plant for the applications like long distance conveyors and Bucket Elevators General Purchase belts and Heat resistant belts for Cement Industry Shriram Beltings India Pvt Ltd These liners are bonded on to steel surfaces and are extremely effective for prevention of wear and tear due to high particle velocity, impingement, abrasion and impact They are extensively used for lining of equipment prone to severe wear in core sector industries such as cement, steel and powerDeccan Mechanical and Chemical Industries

MINING ,QUARRIES/ EARTHMOVING – Arcwel – Hardfacing Die

HAMMER MILL CRUSHER (COAL PACTORS ) widely used crusher system Made from austenitic manganese steel or low alloy cast steel Problem: The Hammers crushing the raw materials are subject to extreme impact/pressure and abrasion and tend to suffer wear and tear Solution: Rebuild worn hammers by using one of the following Welding materialsCement industry The cement industry has provided our biggest customer base since our founding the severe abrasion experienced in cement mills, chutes and hoppers, gives the industry a serious need for equipment protections Our chromium carbide overlay wear plate/lining provide the best solutions in the world for cement mill rollers of all typesChromium carbide wear plate Caster Metallurgical CoThe cement industry is a serious dust pollution industry In the cement production process, there are at least 30 dusting points from material mining to cement packaging Except for electrostatic precipitator and pulse jet bag filter , the cyclone dust collector is also the dust removal equipment we often applied in cement Industrial Cyclone Dust Collector AGICO Cement Plant

Gearbox Repair for the Power Generation Industry

Roller Mill Drives (Crushers/Pulverizers) – Realize successful field operation, crushing coal, limestone, hard rock ores, and other materials into reduced particle size for processing by relying on roller mill drive gearbox repair services from Philadelphia Gear – the manufacturers of one of the most successful lines of dynamic pulverizer comminution process like Cement Mill, Raw Mill and Coal Mills Fosroc’s Cemax range of grinding aids and performance enhancers can save up to 40% of grinding cost Cemax Products CONSTRUCTIVE Reduction in equipment wear and tear Producing better and unique type of cement Reduction in CO 2 Emission through clinker replacementFosroc Grinding Aids Performance Enhancers CEMAX Cement Cement Mill Wear Tear Area And Solution Ball Mill Ball mill machine is widely applied in the industries such as cement silicate product refractory fertilier mineral processing of ferrous and nonferrous metal and glass ceramic etc It is mainly used to make dry or wet powder grinding of various ores and other grindable materials Cement Cement Mill Wear Tear Area And Solution

Cement production and wearresistant solutions Hardox

Cement manufacturing involves wear and tear of many equipment parts due to abrasion, mainly from quartz and illite contamination of the limestone By selecting just the right wear material for every stage in the cement production chain, we can help you to maximize uptime and minimize maintenance from the limestone quarry to the moment the Apr 12, 2021 Widely used in coal conveying, pulverizing, ash discharge systems for thermal power generation, and material conveying and batching systems in metallurgy, iron and steel, cement and other industries Such as coal mill outlet pipe, coarse and fine powder separator inlet pipe, primary air duct elbow, pulverized coal pipe, dust removal pipe, ash Wearresistant ceramic elbow solves difficult problems In the beneficiation operations of mines and other industries, the wear and tear of the wearresistant liner of the ball mill or rod mill is very rapid A φ15m*3m ball mill normally operates for one year, and the wearresistant highmanganese steel consumed The steel plate needs to exceed ten tons, which has greatly increased the production Application of Wearresistant Liner in Mine Ball Mill EB

Spare part packages for mechanical drive technology

Challenges in the cement and minerals industries The cement and minerals industries are characterized by KMPS gear units are used for coal mills in the medium power range, combining a bevel gear stage with a helical normal wear and tear, by stocking parts on site Thus, depending on the package and type of breakdown, the Reduces wear and tear of gears by providing excellent lubrication properties For all type of heavyduty girth gear in cement, coal mill in power plants, sugar, steel plants, calciner in soda plant and chemicals with central lubrication systemlubgraf products4) High wear and Tear resistance properties We offer wide range Chevron Belt Belts for Cement plant for the applications like quarry, mining etc We offer Steel Cord Belts for Cement plant for the applications like long distance conveyors and Bucket Elevators General Purchase belts and Heat resistant belts for Cement Industry Shriram Beltings India Pvt Ltd

CCO plate Caster metallurgical Co

Cement industry The cement industry has provided our biggest customer base since our founding the severe abrasion experienced in cement mills, chutes and hoppers, gives the industry a serious need for equipment protections Our chromium carbide overlay wear plate/lining provide the best solutions in the world for cement mill rollers of all typesQuality suffers Plus, less frequent larger adjustments that rely on subjective human judgement results in higherthannecessary electricity usage and greater wear and tear on machinery ES Processing enables cement mills to leverage databased APCs to assure consistent product qualityES Processing Cement IndustryHAMMER MILL CRUSHER (COAL PACTORS ) widely used crusher system Made from austenitic manganese steel or low alloy cast steel Problem: The Hammers crushing the raw materials are subject to extreme impact/pressure and abrasion and tend to suffer wear and tear Solution: Rebuild worn hammers by using one of the following Welding materialsMINING ,QUARRIES/ EARTHMOVING – Arcwel – Hardfacing Die

Repair and Maintenance Solutions ESAB Welding Cutting

Wear and tear are inevitable, but an extended shutdown or unplanned breakdown Cement Industry Our wide selection of products, combined with application knowledge, delivers the greatest quality, value, and productivity Contact an expert Steel Mills IndustryOct 25, 2019 Wear and tear (1) the spindle cone liner of the cone cone of the cone crusher has obvious wear at the upper mouth, and a narrow strip at the lower mouth, with no contact in the middle; (2) the thin side of the eccentric shaft sleeve at the top of the cone bush is seriously worn, while the thick side of the eccentric shaft sleeve at the bottom Reasons for wear of eccentric parts of cone crusher and Jan 14, 2021 A mill is used in various industries to process raw materials Mill liner is used to increase efficiency, performance, and life; it also protects a mill from wear and tear This factor is likely to project the growth of the mill liner market during the forecast period growth in the mining industry is resulting in rising demand for mills Mill Liner Market Estimated to Flourish by 2027 –

Gearbox Repair for the Power Generation Industry

Roller Mill Drives (Crushers/Pulverizers) – Realize successful field operation, crushing coal, limestone, hard rock ores, and other materials into reduced particle size for processing by relying on roller mill drive gearbox repair services from Philadelphia Gear – the manufacturers of one of the most successful lines of dynamic pulverizer