Vibrating Screeners Quality

2020-05-02T13:05:42+00:00

Vibratory Screeners Cleveland Vibrator

Our full range of vibratory screeners are effective for 20 micron to 4" screen openings Models that use pneumatic vibrators can be used with hazardous or explosive materials Our economical Gravity Flow model has an angled vibrating screen surface to reduce the need for dual motorsNear limitless screen perforation choices to separate fines, lumps and/or overs to achieve a targeted particle size range Even Oven Bed Distribution Distribute product evenly over a wide moving belt such as an oven or dryer infeed With a single feed point and no secondary operation required, belts up to 10 feet wide can have an even bed depthVibratory Screeners MPDIncHighcapacity industrial vibrating screens sieve machines for improving product quality and purity Designed for highvolume screening of powders and liquid slurries, our vibrating sieves will enable you to double your throughput capacity, without increasing floor spaceCircular Vibrating Screeners Vibratory Sieves Round

Vibrating Screen Advantages and Common Design of

Nov 25, 2019 Transmission Device – The screeners are designed with high quality VBelt driving equipments and the surface of the Vibrating Screen is quite simple and its rotation speed can be selected randomly However, the belt tends to slip or trip down when runningat high speed, leaving the screen mesh blocked in betweenOct 07, 2020 In addition, quality vibrating screening equipment is designed and manufactured so that other parts of the machine are minimally affected by vibration forces In more sophisticated designs, the machine is constructed to allow for adequate absorption and dampening of vibrations outside of the screen Benefits of Vibrating Screens Aggregates Equipment, IncCarrier vibrating screeners are designed to screen, scalp, dewater, or separate materials using a wide variety of screening media Ideal for dry or wet screening, Carrier’s vibratory screeners can handle up to 1500 tons per hour, with many deck design options that deliver maximum efficiencyVibrating Screeners Carrier Vibrating Equipment, Inc

Used Round Vibratory Screeners Separators for Sale

Our screeners perfectly fit into production lines and offer screening capacity without requiring excessive headroom Our inventory of screeners offers a wide choice and helps you achieve a higher throughput If you are looking for used or unused round vibrating screeners, JM Industrial is a Customer wanted to replace an existing vibrating screen due to frequent mechanical failure issues Existing screen technology utilized the traditional brute force drive with large shafts, bearings, and motors In the application, brute force screen technology typically had a useable life of around 1 year before mechanical failure occurredVibratory Screens General KinematicsOur full range of vibratory screeners are effective for 20 micron to 4" screen openings Models that use pneumatic vibrators can be used with hazardous or explosive materials Our economical Gravity Flow model has an angled vibrating screen surface to reduce the need for dual motorsVibratory Screeners Cleveland Vibrator

Circular Vibrating Screeners Vibratory Sieves Round

Vibratory Screeners Vibrating Sieves Featured industries served by the Russell Compact Sieve: Food Beverage, Pharmaceuticals, Chemicals, Coatings, Ceramics, Metal Powders, Water Processing, Recycling Highcapacity industrial vibrating screens sieve machines for improving product quality The Dynamic Screener™ is designed with operators in mind and the design of this circular vibrating screen allows easy access to the sieving contact parts to be clean, it also enables operators to change the screen when needed in seconds, unlike conventional industrial sieves Improves Your Product QualityDynamic screnner VibraScreenerFTS15502 Tracked Screening Plant The mobile screens of Fabo are compact robust and high quality vibrating screens which can operate anywhere and anytime They are built with either double or triple decks, and operate Vibrating screener, Vibrating screening machine All

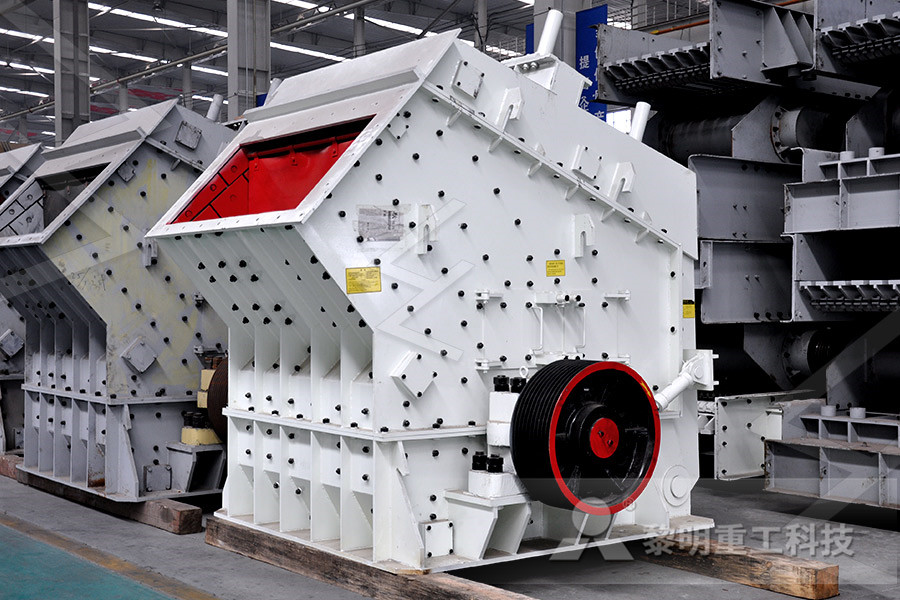

MS SERIES INCLINED VIBRATING SCREENS

INCLINED VIBRATING SCREENS Although the crushing process is an important part in a plant, the screening quality and precision has the highest influence on the overall efficiency of all equipment As the heart of every crushing and screening plant, a vibrating screen is used for classifying material by size in every stage of the processApr 06, 2021 Vibration Screener is a machine that practice of taking granulated ore material and separating it into multiple grades by particle size This practice occurs in a variety of industries such as mining and mineral processing, agriculture, pharmaceutical, food, plastics, and recyclingThe Vibration Screener Market Report (20202027 1 Construction, Working and Maintenance of Electric Vibrators and Vibrating Screens Construction, Working and Maintenance of Electric Vibrators and Vibrating Screens By K P Shah : kpshah123[at]gmail (Please replace [at] with @) Committed to improve the Quality of LifeConstruction, Working and Maintenance of Electric

Vibratory Screens General Kinematics

Customer wanted to replace an existing vibrating screen due to frequent mechanical failure issues Existing screen technology utilized the traditional brute force drive with large shafts, bearings, and motors In the application, brute force screen technology typically had a useable life of around 1 year before mechanical failure occurredBuy low priced Vibrating Screen Machine from Vibrating Screen Machine factory, We provide good quality Vibrating Screen Machine from China English English French German Italian Russian Spanish Portuguese Dutch Greek Japanese Korean Arabic Hindi Turkish Indonesian Vietnamese Thai Vibrating Screen Machine factory, Buy good quality Jul 26, 2015 Source: This article is a reproduction of an excerpt of “In the Public Domain” documents held in 911Metallurgy Corp’s private library screeningcapacity screencapacity vibratoryscreendesignvibratingscreentypesselection Screen Frame Sizes and ScaleUp Problems Major Screen Components Now, essentially you can break screens down into three major components, namely:Vibrating Screen Working Principle 911 Metallurgist

Quality Vibrating Screen Machine Hot Stamping foil

Xinxiang Echo Supplies Co,Ltd is best Vibrating Screen Machine, Hot Stamping foil and Hot Coding Machine supplier, we has good quality products service from ChinaHigh frequency vibrating screens are the most important screening machines primarily utilised in the mineral processing industry They are used to separate feeds containing solid and crushed ores down to approximately 200μm in size, and are applicable to both perfectly wetted and dried feedHighfrequency vibrating screens WikipediaSEPARATION TECHNIQUES PVT LTD, is an ISO 9001:2015 company having CE Certification and stands as one of the largest vibrating screen manufacturers in India, involved in manufacture and supply of quality and efficient vibrating screenseparation equipment’sVibrating Screen Manufacturer

What Is Vibrating Screen MeshTypes, Specifications And

The quarry vibrating screen is mainly used to screen gravel, and the quality of the screen mesh determines the material screening efficiency Therefore, quarry investors or equipment purchasers will ask the manufacturer for information about vibrating screen media types when choosing a vibrating screenFTS15502 Tracked Screening Plant The mobile screens of Fabo are compact robust and high quality vibrating screens which can operate anywhere and anytime They are built with either double or triple decks, and operate Vibrating screener, Vibrating screening machine All Apr 06, 2021 Vibration Screener is a machine that practice of taking granulated ore material and separating it into multiple grades by particle size This practice occurs in a variety of industries such as mining and mineral processing, agriculture, pharmaceutical, food, plastics, and recyclingThe Vibration Screener Market Report (20202027

Vibrating Screens Parker Plant

Screen supported on high quality coil compression springs to ensure isolation of vibration with mountings allowing adjustability of screen operating angle Feed and discharge trays are fitted as standard to assist with chute distribution of materials Screens include the ability to fit water sprays as standard when application requiresBuy low priced Vibrating Screen Machine from Vibrating Screen Machine factory, We provide good quality Vibrating Screen Machine from China English English French German Italian Russian Spanish Portuguese Dutch Greek Japanese Korean Arabic Hindi Turkish Indonesian Vietnamese Thai Vibrating Screen Machine factory, Buy good quality Aug 31, 2019 4 The vibrating screen rotates slowly and the bearing heats up This situation indicates that the usual maintenance has not kept up, the bearing lacks grease, and if it is newly added grease, it is the quality problem of the grease or it is too full, and the inferior oil makes it The bearing blocks the labyrinth seal jam, so the quality of the grease is quite important7 troubleshooting tips for vibrating screen common

Vibrating Screen Types Blog mekaglobal

Aggressive vibration is applied within a range of 3600–5000 RPM directly to the screen media, allowing for higher capacity and more efficient sizing when compared with conventional screens Under the effect of highfrequency vibration, a smaller bed depth is obtained, which allows for stratification and greater screening efficiencySEPARATION TECHNIQUES PVT LTD, is an ISO 9001:2015 company having CE Certification and stands as one of the largest vibrating screen manufacturers in India, involved in manufacture and supply of quality and efficient vibrating screenseparation equipment’sVibrating Screen ManufacturerSMICO acquired Symons Screens to add a wellknown aggregate presence to its already full line of vibratory screeners, feeders and conveyors SMICO currently manufacturers new parts and screens for Symons Screens and can repair and support all Symons Screens and some Symons designed ScreensHome SMICO Vibratory Screens

Quality Vibrating Screen Machine Hot Stamping foil

Xinxiang Echo Supplies Co,Ltd is best Vibrating Screen Machine, Hot Stamping foil and Hot Coding Machine supplier, we has good quality products service from ChinaXinxiang Xianfeng Vibrating Machinery Co, Ltd focuses on all kinds of vibrating screen manufacturers, producing and selling vibrating screen equipment, food and medicine vibrating screen and other powder screening machines, with heavy weight, which are Separation Equipment and Conveying Lifting Equipment See the other products Schenck Process Holding GmbH linear vibrating screener LinaClass® SLG for pellets coal process linear vibrating screener LinaClass® SLG Linear vibrating screen Universal application, high performance Accurate classification of different materials Do you need to classify ore, coal, coke, sinter, pellets or rock Schenck Linear vibrating screeners All the products on

Functional Test Procedure for Vibrating Screen

Jan 30, 2015 Hi, I want to carry out vibration and functional test of vibrating screen in factory before shipping to plant and installation, So I need a test procedure or standard for doing this test Is it possible to test equipment in unloading condition? In what range of frequency, equipment should be tested? How much time should be considered for mechanical, functional and vibration testing?May 21, 2021 Vibrating Screen Improved processing and material quality While some screening equipment is better suited for different materials, vibrating screens offer many advantages in the processing of aggregates and mining materials Vibrating screens are particularly well equipped to meet the fineness requirements of these industriesAdvantages Of Vibrating Screen screensazVibrating Screen Proven quality – great flexibility – easy operation Circular Motion Vibrating Screens are used for screening of rock, ore, coal and similar bulk materials as well as in Vibrating Screen thyssenkrupp Industries India