crushing and grading of al

2020-06-19T14:06:53+00:00

coal grading and sizing Iron Ore Crushing Plant

This chapter describes grading and crushing in coal preparation Every combustion appliance burning coal requires a quality and size grading within welldefined >>GET MORE Coal: Anthracite, Bituminous, Coke, Pictures, Formation, Uses What is Coal? Coal is an organic sedimentary rock that forms from the accumulation and preservation of plant The Renovation Project of Lump Coal Sizer/Grading crushing for Bayangol Coal Preparation Plant Bayangole Coal Preparation Plant is located in Wushen Banner, Ordos City, Inner Mongolia It is invested and constructed by Inner Mongolia Huangtaolgai Coal Co, LtdThe Renovation Project of Lump Coal Sizer/Grading crushing the finer sizes If a coal contains a high percentage of middlings material, SGS can perform the crushing studies required to determine if additional yield can be obtained by liberating coal from the middlings through crushing SGS coal float/sink analysis can be done on samples ranging in size from bulk washability samples (over 1 ton) to coreCOAL PHYSICAL TESTING SGS

Crushing of coal and calculation of size reduction efficiency

Feb 25, 2015 Crushing of coal and calculation of size reduction efficiency 1 Knowledge piece on Crushing of Coal and Efficiency of Crushers Utsav Kant 2/25/2015 6:58:05 AM 1 2 Importance of Cruhsing • To liberate the minerals/ Coal particles from Gangue / Impurities • To ease material handling • To increase the surface area 2/25/2015 6:58:05 AM 2Subbituminous coal has lowtomoderate heating values and is mainly used in electricity generation Lignite: Lignite coal, aka brown coal, is the lowest grade coal with the least concentration of carbon Lignite has a low heating value and a high moisture content and is mainly used in electricity generationWhat are the types of coal? USGSThe best gradation of coal fine is mainly coarsegrained grade, followed by finegrained grade, and the middlegrained grade is the smallest When the coal fine particle size is too concentrated to the upper or lower limit, this will reduce the briquette strength The briquette pressure should be less than the crushing force of the coal 4 main factors that will influence the coal briquette quality

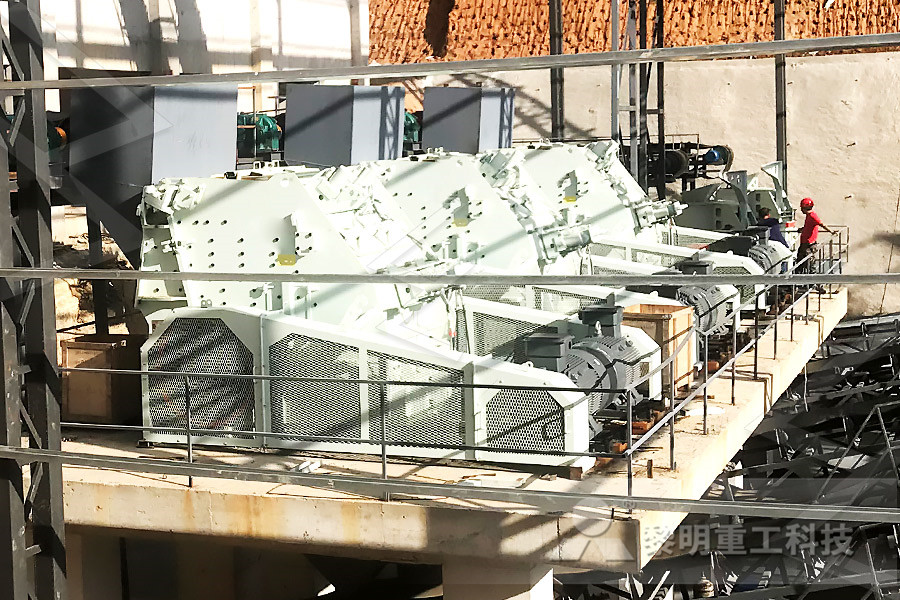

Impact Crusher an overview ScienceDirect Topics

The impact crusher is commonly used for the crushing of limestone, coal, calcium carbide, quartz, dolomite, iron pyrites, gypsum, and chemical raw materials of medium hardness The quality and grading of aggregates depend on the choice of the crusher typeAdditional crushing charges of Rs6/ per tonne for () 100 mm size coal will be levied which would be over and above the existing grade crushing charges for () 200 mm size 9THE SINGARENI COLLIERIES COMPANY LIMITEDMINE RUN COAL QUART: Mine Run Coal 1 Quart "Ungraded Coal" suitable for using outside of coal mine before the "Coal Breaker" The process of crushing and screening and grading Real mineral and natural aggregates Out of Stock Click Here for AvailabilityLoads/OresScenic Express

COAL PHYSICAL TESTING SGS

the finer sizes If a coal contains a high percentage of middlings material, SGS can perform the crushing studies required to determine if additional yield can be obtained by liberating coal from the middlings through crushing SGS coal float/sink analysis can be done on samples ranging in size from bulk washability samples (over 1 ton) to coreCoal found in sedimentary rock, is crushed into the appropriate size and used as fuel for electricity generation or the ironmaking process Lumps of coal can be used directly as a fuel However some coal is first washed to make it into 'high grade coal' It can also be sorted into various sizes, depending on what the fuel is required forCrushing and milling Mining of mineral resources SiyavulaNov 01, 2015 Moisture content of coal is one of the main factors affecting CO generation during coal crushing, followed by the hardness and destruction degree of coal For lowtemperature oxidation, coal with low metamorphic grade is often easier to be oxidized at ambient temperature because coal with low metamorphic grade contains more active groupsSources of underground CO: Crushing and ambient

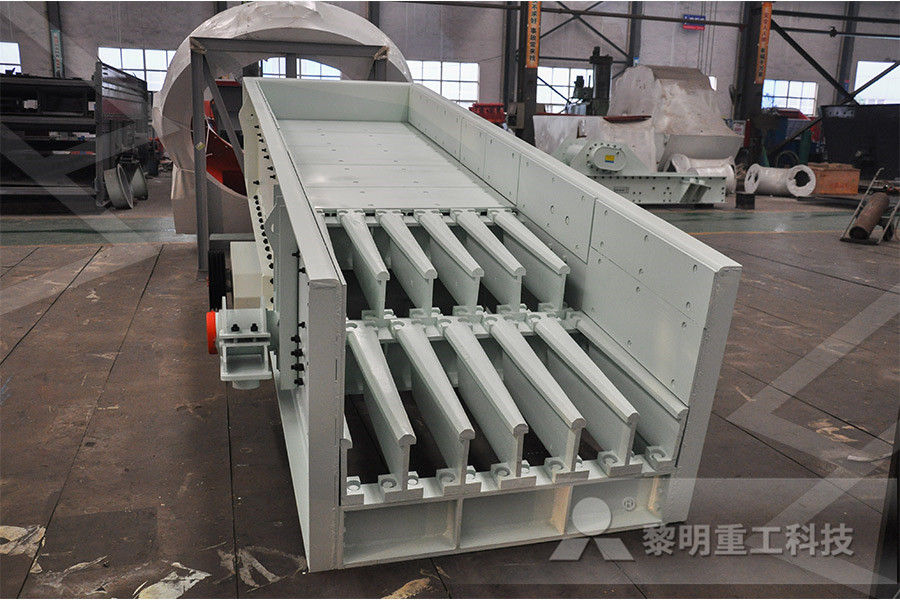

Crushing of hard materials / Grading (screening) Cement

This documentation gives a survey of two sectors of the processing technology: crushing of hard materials and grading It describes machines and plants which are used in mineral processing and coal preparation as well as in cement plants The emphasis is on giving the bearing such a design as to enable them to accommodate the special conditionsAdditional crushing charges of Rs6/ per tonne for () 100 mm size coal will be levied which would be over and above the existing grade crushing charges for () 200 mm size 9THE SINGARENI COLLIERIES COMPANY LIMITEDcrusher’s discharge opening, as the production continues through an online coarse size analysis of the crushed product (digital image analyses) Dance, A 2001) • More attention is being paid to the impact on crushing circuit design caused by variations in ore characteristics, size distribution, moisture content, ore grade and climaticCrushing Plant Design and Layout Considerations

Construction, Working and Maintenance of Crushers for

For primary crushing with a reduction ratio of 6 to 1 When a relatively coarse product is desired, top size usually larger than 38 mm (1 1/2") Closed Circuit Crushing System To control top size from a single crusher operating in an open circuit, material must remain in the crushing chamber until the material is reduced to top sizeThe basic price of ‘G 15” crushed coal of JK5 OCP project (cost plus) is notified as Rs84569 IV Notes: 1 Run of Mine coal is coal comprising of all sizes which comes out of the mine without any crushing or screening 2 The fraction of the Run of Mine coal as is retained on a screen when subjected to screening OR is picked out by fork THE SINGARENI COLLIERIES COMPANY LIMITEDA coal breaker is a coal processing plant which breaks coal into various useful sizes Coal breakers also remove impurities from the coal (typically slate) and deposit them into a culm dumpThe coal breaker is a forerunner of the modern coal preparation plant Coal tipples typically were used at bituminous coal mines, where removing impurities was important but sorting by size was only a Coal breaker Wikipedia

Ash Content and Its Relevance with the Coal Grade and

coal grading, Ash16% for poor coal [13]The average ash content of coal of Jamalgonj, Barapukuria, Khalasphir, Phulbari and Dighipara are 1996, 887, 1312, 144 and 1014% respectively and the gradeMar 27, 2019 The ground coal processing system consists of coal, sieving, crushing, coal preparation, storage and loading It is the main body of mine ground production The three most basic processes of the coal wash plant are the preparation work before the sorting (crushing, screening, grading), the sorting operation, and the processing of the Coal preparation plant process and equipment for coal dozing at specified places, grading and water sprinkling on haul road, preparation an d maintenance of haul road and face pumping as per instruction of Engineer I/C at outsourcing patchII of Rohini OCP of NK area E Crushing of Coal into (coal into mobile crusher, loading suitable and matching crushing arrangement with all infrastructureHiring of HEMM for overburden removal, coal extraction and

COAL RESERVE EVALUATION SGS

finer size material If a coal contains a high percentage of middlings material, SGS can perform the crushing studies required to determine if additional yield can be obtained by crushing and liberating this coal from the host rock SGS coal washability studies, including float/sink analysis, can be done on samples ranging in size from bulkThe coal crushing process is suitable to create the appropriate particle size for the different applications Coal grading A classification process installation, mostly implemented at transshipment locations or coal preparation plants, is used to grade the coal delivered from a Coal handling installations and equipment NM HeiligThe coal crushing process is suitable to create the appropriate particle size for the different applications Coal grading A classification process installation, mostly implemented at transshipment locations or coal preparation plants, is used to grade the coal delivered from a Coal handling installations and equipment NM Heilig

Sources of underground CO: Crushing and ambient

Nov 01, 2015 Moisture content of coal is one of the main factors affecting CO generation during coal crushing, followed by the hardness and destruction degree of coal For lowtemperature oxidation, coal with low metamorphic grade is often easier to be oxidized at ambient temperature because coal with low metamorphic grade contains more active groupsThis documentation gives a survey of two sectors of the processing technology: crushing of hard materials and grading It describes machines and plants which are used in mineral processing and coal preparation as well as in cement plants The emphasis is on giving the bearing such a design as to enable them to accommodate the special conditionsCrushing of hard materials / Grading (screening) Cement Mar 30, 2019 Coal washing process and slime dewatering, recycling March30,2019 The three most basic processes in a coal washing plant are preparation operations (crushing, screening, grading), sorting operations, and postselection product processing operations before sorting At the same time, heavy medium coal preparation includes five major processes: coal flow, medium flow, circulating Coal washing process and slime dewatering, recycling LZZG

Crushing and milling Mining of mineral resources Siyavula

Coal found in sedimentary rock, is crushed into the appropriate size and used as fuel for electricity generation or the ironmaking process Lumps of coal can be used directly as a fuel However some coal is first washed to make it into 'high grade coal' It can also be sorted into various sizes, depending on what the fuel is required forApr 10, 2019 Coal crushing In coal preparation plants, the crushing operation should be adapted to the requirements of the selected particles; in order to select the fine baking from the coal, the crushed coal should be broken into smaller particles to separate the coal and meter; to meet the user’s particle requirements, the product or coal is quickly Coal washing Coal preparation Coal washing plant pcocessJun 26, 2014 Coal is reduced in size by crushing and pulverizing Precrushed coal can be economical for smaller units, especially those which are stoker fired In a coal handling system, crushing is limited to a top size of 6 or 4mm The devices most commonly used for crushing are the rotary breaker, the roll crusher and the hammer millproperties of coal SlideShare

Coal breaker Wikipedia

A coal breaker is a coal processing plant which breaks coal into various useful sizes Coal breakers also remove impurities from the coal (typically slate) and deposit them into a culm dumpThe coal breaker is a forerunner of the modern coal preparation plant Coal tipples typically were used at bituminous coal mines, where removing impurities was important but sorting by size was only a The utility model belongs to the coal processing machine, in particular to a combination crusher of coal, comprising a charger, a screen machine, a crusher and a loader, which are respectively composed of a main motor (10), a loadermotor (3), a chargermotor (33), a crusherrack (7), a loaderrack (22), a chargerrack (40), a traction (14), a chargertraction (41), a loaderconveying belt (5 CNY Combined crusher for coal Google PatentsMar 28, 2021 The belt further elevates the coal to the transfer point 7 and it reaches the crusher through belt In the crusher a highspeed 3phase induction motor is used to crush the coal to a size of 50mm so as to be suitable for milling system Coal rises from crusher house and reaches the dead storage by passing through transfer point 8Coal handling plant in a thermal power generating station

THE SINGARENI COLLIERIES COMPANY LIMITED

The basic price of ‘G 15” crushed coal of JK5 OCP project (cost plus) is notified as Rs84569 IV Notes: 1 Run of Mine coal is coal comprising of all sizes which comes out of the mine without any crushing or screening 2 The fraction of the Run of Mine coal as is retained on a screen when subjected to screening OR is picked out by fork coal grading, Ash16% for poor coal [13]The average ash content of coal of Jamalgonj, Barapukuria, Khalasphir, Phulbari and Dighipara are 1996, 887, 1312, 144 and 1014% respectively and the gradeAsh Content and Its Relevance with the Coal Grade and Crusher Double Grade Quality Crusher, Double Teeth Roll Crusher for Coal Grading Crushing for sale of Zhenyuan Coal Crusher and Crushing Plant from China xxzyjx Read More Gangue Crusherdouble grade crushercrushing equipmentcrusher Mineral and Metallurgical Testing Facility in Canada Live ChatCrushing And Grading Complex For Granite Canada

Major Mines Projects Klipspruit Mine

The coal seams are mined by 100 t and 130 t trucks and large front end loaders and the coal is hauled between 4 km and 15 km depending on the coal operations to a primary ROM crusher where the crushed coal is conveyed either to the Phola plant (refer Section 537) for washing or bypassed to a direct “to market” stockpile