grinding media distribution in ball mill r

2021-07-03T16:07:24+00:00

Size Distribution of Grinding Media (Balls) in a Mill

At high speed, they are in the centre This applies to all types of grinding media, eg pebbles, ball or rods This segregation is a result of the fact that at low speed, the force of gravity is stronger than the centrifugal force, so that the grinding media move around the core of the charge The relative movement of the material being ground is greatest at the top of the plant ball mill’s grinding efficiency (Fig 1) The functional performance parameters “mill grinding rate through the size of interest,” and “cumulative mill grinding rates” from both plant and smallscale tests are applied to this task A plant media sizing methodology, and industrial case studies, are provided BackgroundBall mill media optimization Metcom TechCurrent ball milling theory suggests that grinding capacity is influenced by the size of balls charged to the mill In selecting the appropriate ball charge, the first objective is to determine that ball size which will grind the coarse particles most efficiently This size should be the largest ball size charged to the mill The second objective is to provide the correct ball size distribution to Grinding Media 911Metallurgist

Ball Mill Grinding Media Options Orbis Machinery, LLC

26/04/2019 The balls are the grinding media which could be made of ceramic, rubber, steel, etc ball mills operate by rotating around a horizontal axis almost filled with the material to be ground and the grinding media The end result is the reduction of the material to a fine powderBall mills are equipments which has balls as grinding media and used for last step of grinding process There are many factors which effect grinding performance of (PDF) INVESTIGATION OF EFFECTS OF GRINDING MEDIA SHAPES 27/04/2019 A series of studies has been made at the University of California in Berkeley on the grinding of dolomite in a ball mill These tests were made in a specially designed mill in which the input energy can be measured Berlioz has reported data on the size distribution at successive stages of size reduction in this millParticle Size Distribution of Grinding Mill Products

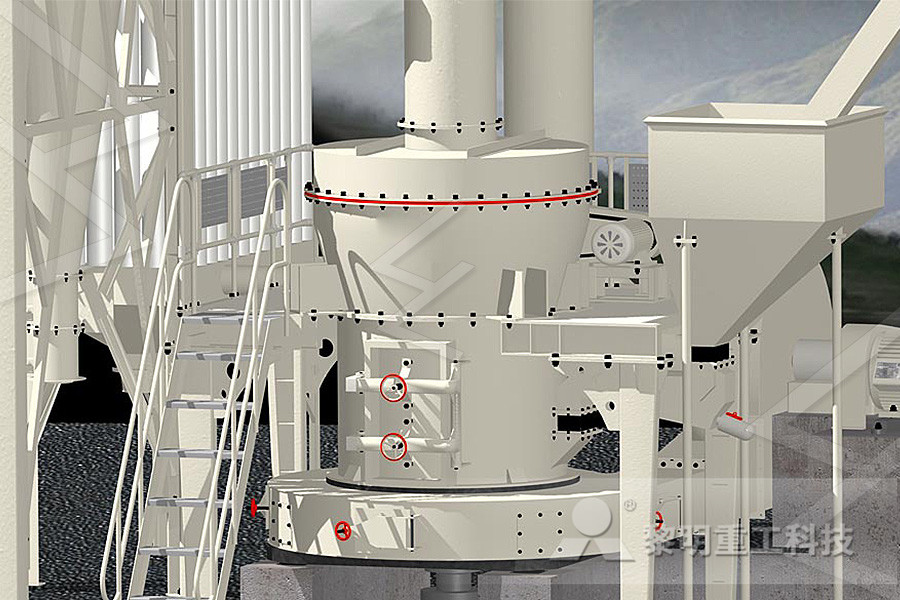

Grinding Mill Design Ball Mill Manufacturer

20/02/2017 Grinding by use of nearly spherical shaped grinding media is termed ball milling Strictly speaking, such media are made of steel or iron When iron contamination is detrimental, porcelain or natural nonmetallic materials are used and are referred to as pebbles When ore particles are used as grinding media this is known as autogenous grinding13/02/2017 If finer grinding is wanted two or three stage grinding is advisable as for instant primary rod mill with 75—100 mm (3″—4″) rods, secondary ball mill with 25—40 mm(1″—1½”) balls and possibly tertiary ball mill with 20 mm (¾”) balls or cylpebs To obtain a close size distribution in the fine range the specific surface of the grinding media should be as high as Ball Mills Mineral Processing MetallurgyGrinding is the process of achieving particle size reduction through attrition and compressive forces at the granular level The grinding media in a ball mill is typically steel or ceramic balls of varying sizes, depending on the feed size, work index of the ore and the size reduction and distribution required in the dischargeBALL MILL AND BALL CHARGING SYSTEMS AUSTRALIA BHT Group

Grinding Media Size Distribution In Ball Mill

Grinding Media Sie Distribution In Ball Mill Machine Mining Dec 26 2017 Several factors affect the efficiency of a ball mill for cement grinding In this article we shall be looking at some of these factors that have been proven to influence grinding efficiency Mill Geometry And Speed According to Bond 1954 the grinding efficiency of a mill depends on the ball mill diameter Ball Mill Cement Mill Grinding Media Distribution Cement millniversal drive ball mills large grinding media for coarse grinding and special lines ensures optimum lifting of the mill charge the size distribution of the grinding media in the coarse grinding compartment is designed for the coarsest particles in the mill feed material and to ensure adequate fineness of the material grinding media distribution in ball millComparative tests were conducted using the two types of grinding media in a laboratory Bond ball mill at various conditions of equality such as media mass, size (PDF) INVESTIGATION OF EFFECTS OF GRINDING MEDIA

grinding media distribution in ball mill physioamkottide

Ball Mill Cement Mill Grinding Media Distribution The basic parameters used in ball mill design power calculations rod mill or any tumbling mill sizing are material to be ground characteristics bond work index bulk density specific density desired mill tonnage capacity dtph operating solids or pulp density feed size as f80 and maximum chunk size product size as p80 23/12/2013 Rod mill is similar to ball mills but it uses long rods for grinding media Autogenous mill is a selfgrinding mill which is used in breakage of larger rocks SAG (SemiAutogenous Grinding) mill is an autogenous mill which uses grinding balls, it is similar to ball mill but has large diameter and short length Vertical mill is used in grinding material at smaller particle Practical 1 : Ball Milling TF Lab 1Ball Mill Grinding Media Options Orbis Machinery, LLC Steel ball grinding media are used in tower mills, Isa mill, rotary mills, semiautogenous grinding (SAG) mill Plastic Grinding Media Plastic ball mills are made from high quality and special resin Plastic ball mills can be used as a substitute for metallic ball mill get pricegrinding media distribution in ball mill

Assessing load in ball mill using instrumented grinding media

01/11/2021 To validate the proposed identification model for ball mill, 5 × 60 samples were randomly selected from the signals collected by instrumented grinding media in five load states 80% of signals were used as training set while the remaining 20% were used for testing (Gholamy et al, 2018) Specifically, severe underload, underload, normal load, suboptimal and overload grinding media distribution in ball mill; product list K Series Mobile Crushing Plant; Mobile Vibrating Screen; Belt Conveyer; Sand Washing Machine; S5X Series Vibrating Screen; GF Series Vibrating Feeder; Ball Mill; Raymond Mill; MW Series Micro Powder Mill; T130X Superfine Grinding Mill; MTW Trapezium Mill ; LM Vertical Mill; 5X Pendulum Roller Mill; grinding media distribution in ball mill261 Ball size distribution in tumbling mills 37 262 Milling performance of a ball size distribution 40 27 Summary 41 Chapter 3 Experimental equipment and programme 43 31 Laboratory grinding mill configuration 43 32 Preparation of monosize grinding media 44 33 Feed material preparation 46 331 Coal sample collection at Tutuka power station 46 332 EFFECT OF BALL SIZE DISTRIBUTION ON MILLING PARAMETERS

cement mill grinding media distribution xls

Cement Mill Grinding Media Page 1 of 12017 11 1 Cement Mill Grinding Media Dear Experts, I want to know about the GM size wise percentage distributiBall mill grinding efficiency is directly influenced by the size distribution of the grinding balls in the mill Determining the ball size (or sizes) that should be added to a plant ball mill to obtain optimal performance requires consideration of a number of factors including: circuit feed size distribution, target grind size, and ore breakage characteristicsGrinding Media Sizing – MetcomComparative tests were conducted using the two types of grinding media in a laboratory Bond ball mill at various conditions of equality such as media mass, size (PDF) INVESTIGATION OF EFFECTS OF GRINDING MEDIA

media distribution grinding in a ball mill dry – Grinding

media distribution grinding in a ball mill dry [ 49 4483 Ratings ] The Gulin product line, consisting of more than 30 machines, sets the standard for our industry We plan to help you meet your needs with our equipment, with our distribution and product support system, and the continual introduction and updating of products Related Posts » Production line of fly ash ball grinding media size distribution in ball mill The size distribution of the balls in the mill charge appears to have no significant effect upon the size distribution of the product nor upon the rate of grinding provided that the size distribution of the balls is not too unreasonably chosen Thus no significant difference in the grinding characteristics can be detected in the grinding media size distribution in ball millGrinding media distribution chart of both chamber cement ball millCement mill grinding media distribution isafisCement mill grinding media distribution xls numeralsGrinding media for millsWe have recently started producing a range of grinding balls to be used in the cement and mining industriesWe can produce themGrinding Media Distribution In Ball Mill Center

media distribution in ball mill vdpacbe

Ball Mill Charge Machine Size Distribution Of Grinding Ball Mill Charge Machine Size Distribution Of Grinding Media TECHNICAL NOTES 8 GRINDING R P King 82 ROOLVLRQ mp is the mass of any particle (media or charge) in the mill and Dm is the diameter of the mill inside the liners > Get Price The effect of grinding media J performance on Ball Mill Grinding Media Options Orbis Machinery, LLC Steel ball grinding media are used in tower mills, Isa mill, rotary mills, semiautogenous grinding (SAG) mill Plastic Grinding Media Plastic ball mills are made from high quality and special resin Plastic ball mills can be used as a substitute for metallic ball mill get pricegrinding media distribution in ball millgrinding media distribution in ball mill Nov 01, 2017 CementMill Grinding Media Dear Experts, I want to know about the GM size wise percentagedistributionin a 2 chamber close circuit OPCball millMilldim 34 x 125Mediaload 128 MT high chromegrinding media distribution in ball mill Kuwait

Cement Mill Grinding Media Distribution Xls ball Mill

Cement grinding media charging excel shitcement grinding media charging excel shitCement mill notebook 44 grinding media 441 grinding ball charge in mills 442 mill charging 443 total grinding ball charges weight 444 chemical grinding efficiency , cement mill grinding media distribution xlsCement Mill Grinding Media Page 1 of 12017 11 1 Cement Mill Grinding Media Dear Experts, I want to know about the GM size wise percentage distributicement mill grinding media distribution xls