equipment needed to process gold ore

2021-12-10T23:12:35+00:00

Gold Refining Systems Machines and Equipment for Gold

For the first time ever, gold processing can be done with a high level of confidence and safety, from a very small jewelry business to medium scale refinery The process is simple and easy By using our REFINEIT system, all the user has to do is melt the gold in an ingot, submerge the gold in the gold refining equipment Gold processing Gold processing Mining and concentrating: The nature of the ore deposit determines the mining and mineral processing techniques applied Oxide ore deposits are frequently of such low grade (eg, 3 to 10 parts per million) that extensive Gold processing Mining and concentrating BritannicaSep 07, 2017 The hashing stage (corresponding to metal extraction and recovery stages) is a little more complex for gold ores, as the optimal process flowsheet selection choice is heavily dependent on a good understanding of two fundamental geometallurgical parameters, the gold mineralogical associations, and the gold particle size and liberation Gold processing 101 Mining Magazine

Gold Mining and Processing: Everything you Need to Know

The Basics of Gold Mining and Processing Placer deposits, such as streambeds where people can pan for gold, are not the typical locations used by commercial gold mining companies The process begins when geologists take ore samples to determine the best places for companies to mine Once mining engineers know where gold May 15, 2021 The Miller process uses gaseous chlorine to extract impurities when gold is at melting point; impurities separate into a layer on the surface of the molten purified gold The Miller process is rapid and simple, but it produces gold of only about 995 percent purity The Wohlwill process increases purity to about 9999 percent by electrolysisProcessing, smelting and refining gold World Gold CouncilFor the first time ever, gold processing can be done with a high level of confidence and safety, from a very small jewelry business to medium scale refinery The process is simple and easy By using our REFINEIT system, all the user has to do is melt the gold in an ingot, submerge the gold in the gold refining equipment we provide, then waitGold Refining Systems Machines and Equipment for Gold

Gold processing 101 Mining Magazine

Sep 07, 2017 The hashing stage (corresponding to metal extraction and recovery stages) is a little more complex for gold ores, as the optimal process flowsheet selection choice is heavily dependent on a good understanding of two fundamental geometallurgical parameters, the gold mineralogical associations, and the gold particle size and liberation Jan 18, 2017 The Amalgamation Process that employed mercury in the recovery of gold from the ore is no longer used at most major mines, but goldrich ore often has some traces of mercury that may still stick to gold even after the precipitation and the leaching process If not removed from the ore this mercury is likely to under volatilization during the The Gold Smelting Process Melting, Smelting Refining Mar 01, 2019 Gold smelting is also an alternative to gold melting since many people struggle to melt gold successfully Smelting Gold Everything You Need to Know There are a variety of methods that you can use for smelting gold, but the main equipment necessary is a heat source and a crucible, a heatproof container for the goldEverything You Need to Know About the Process of Smelting Gold

Establishing thE ProcEss MinEralogy of gold orEs

during gold ore processing Steadily rising gold prices are also stimulating the need for gold process mineralogy due to the increasing demand for and production of the yellow metal At SGS Lakefield Research, gold process mineralogy studies are conducted routinely on all types of gold ores and mill products to assist in a wide varietyThis is the gold I collected in a bucket over three months Sort the gold into circuits that need cleaning, gold plated parts, gold plated pins, gold fingers, and solid gold large and small Use a magnet to separate all gold plated steel this needs a different process than I am demonstratingGold Recovery : 8 Steps (with Pictures) Instructables*Cupellation is a refining process in metallurgy, where ores or alloyed metals are treated under high temperatures and controlled operations to separate noble metals, like gold and silver, from base metals like lead, copper, zinc, arsenic, antimony or bismuth, present in the ore Breathing equipment You will need a chemical mask rated AT Gold Recovery Correctly : 12 Steps Instructables

The true cost of producing an ounce of gold Provident

May 23, 2017 Explore the process of gold mining and refining, constructing roads and buildings, and bringing in mining equipment Gold ore can then be physically extracted from the ground Once the mine is tapped out, the mining company may be required (depending on the location) to restore and rehabilitate the site to premining conditions, within required for gold leaching by cyanidation Another example of chemical interference is the presence of graphitic carbon in a gold ore This species, which occurs is a more efficient process for slowerleaching gold ores, and has certain other advantages over CIL, such as smaller carbon elution and regeneration circuitsFLOWSHEET DEVELOPMENT FOR GOLD OREBODIES When The result of this process is 995 percent pure gold The final step is to cast the gold into electrodes or anodes and place them in an electrolytic cell The refiners will then pass an electric current through the cell At the end of this process, the gold will be 9999 percent pure Reclaiming the Mine; No gold How Gold Is Refined: A StepByStep Guide Pease Curren

Gold and Platinum Refining Recovery Systems / Equipment

An overview on how to refine precious metals There are many kinds of materials that yield pure gold, platinum, or silver when refined Though it's usually a little intimidating the first time you do anything, refining precious metals yourself is relatively easy to do (even with no experience) provided you have the right information, supplies, and equipmentNov 22, 2020 Prospecting for gold can be a fun hobby, though it’s a lot of work! You may be able to harvest gold flakes from rock if it contains gold among its minerals The safest way to extract gold from rocks at home is to crush the rocks However, you might use mercury to extract the gold if you’re able to obtain some, though this is dangerousEasy Ways to Extract Gold from a Rock (with Pictures The Basics of Gold Mining and Processing Placer deposits, such as streambeds where people can pan for gold, are not the typical locations used by commercial gold mining companies The process begins when geologists take ore samples to determine the best places for companies to mine Once mining engineers know where gold Gold Mining and Processing: Everything you Need to Know

Processing, smelting and refining gold World Gold Council

May 15, 2021 The Miller process uses gaseous chlorine to extract impurities when gold is at melting point; impurities separate into a layer on the surface of the molten purified gold The Miller process is rapid and simple, but it produces gold of only about 995 percent purity The Wohlwill process increases purity to about 9999 percent by electrolysisSep 07, 2017 The hashing stage (corresponding to metal extraction and recovery stages) is a little more complex for gold ores, as the optimal process flowsheet selection choice is heavily dependent on a good understanding of two fundamental geometallurgical parameters, the gold mineralogical associations, and the gold particle size and liberation Gold processing 101 Mining MagazineMar 01, 2019 Gold smelting is also an alternative to gold melting since many people struggle to melt gold successfully Smelting Gold Everything You Need to Know There are a variety of methods that you can use for smelting gold, but the main equipment necessary is a heat source and a crucible, a heatproof container for the goldEverything You Need to Know About the Process of Smelting Gold

Establishing thE ProcEss MinEralogy of gold orEs

during gold ore processing Steadily rising gold prices are also stimulating the need for gold process mineralogy due to the increasing demand for and production of the yellow metal At SGS Lakefield Research, gold process mineralogy studies are conducted routinely on all types of gold ores and mill products to assist in a wide varietyThe result of this process is 995 percent pure gold The final step is to cast the gold into electrodes or anodes and place them in an electrolytic cell The refiners will then pass an electric current through the cell At the end of this process, the gold will be 9999 percent pure Reclaiming the Mine; No gold How Gold Is Refined: A StepByStep Guide Pease Currenrequired for gold leaching by cyanidation Another example of chemical interference is the presence of graphitic carbon in a gold ore This species, which occurs is a more efficient process for slowerleaching gold ores, and has certain other advantages over CIL, such as smaller carbon elution and regeneration circuitsFLOWSHEET DEVELOPMENT FOR GOLD OREBODIES When

Gold Recovery : 8 Steps (with Pictures) Instructables

This is the gold I collected in a bucket over three months Sort the gold into circuits that need cleaning, gold plated parts, gold plated pins, gold fingers, and solid gold large and small Use a magnet to separate all gold plated steel this needs a different process than I am demonstratingMay 23, 2017 Explore the process of gold mining and refining, constructing roads and buildings, and bringing in mining equipment Gold ore can then be physically extracted from the ground Once the mine is tapped out, the mining company may be required (depending on the location) to restore and rehabilitate the site to premining conditions, within The true cost of producing an ounce of gold ProvidentNov 22, 2020 Prospecting for gold can be a fun hobby, though it’s a lot of work! You may be able to harvest gold flakes from rock if it contains gold among its minerals The safest way to extract gold from rocks at home is to crush the rocks However, you might use mercury to extract the gold if you’re able to obtain some, though this is dangerousEasy Ways to Extract Gold from a Rock (with Pictures

How Is Gold Formed? Origins and Process

May 06, 2019 Gold is a chemical element easily recognized by its yellow metallic color It is valuable because of its rarity, resistance to corrosion, electrical conductivity, malleability, ductility, and beauty If you ask people where gold comes from, most will say you obtain it from a mine, pan for flakes in a stream, or extract it from seawaterA gold smelter refers to any equipment or process used to extract gold from its ore, usually by heating For example: a foundry induction furnace, propane furnaces, electric arc furnaces, etc Back to GuideGold Melting Furnace, CE Approved Gold Smelting Machine Mar 15, 2019 In gold cyanidation leaching process like CIL, CIP process, the commonly used gold recovery chemicals are sodium cyanide and ecofriendly gold dressing agent Of course, it’s necessary to choose the suitable gold recovery chemical for the gold recovery plant according to the properties of the gold ore itself, the project condition and What Are Commonly Used Gold Recovery Chemicals? CNFREE

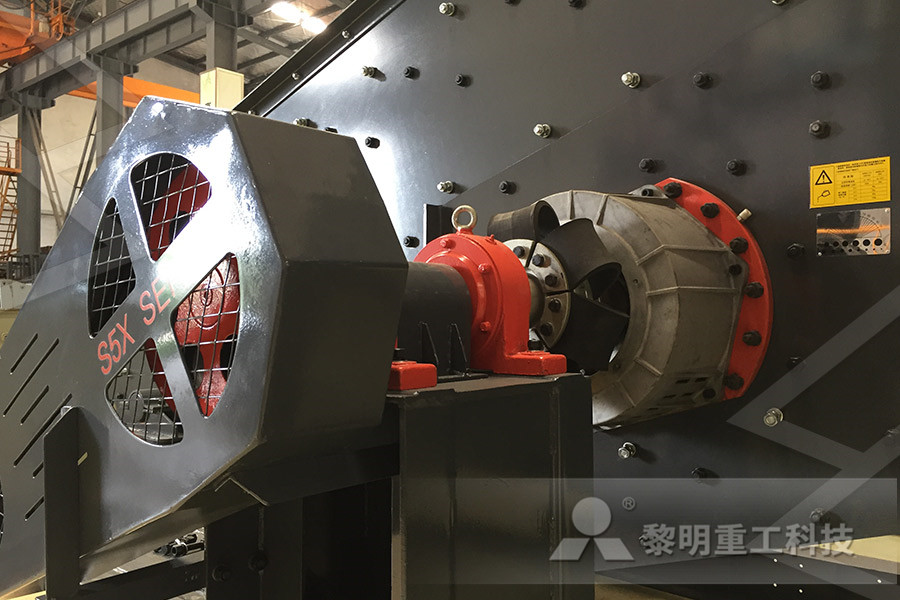

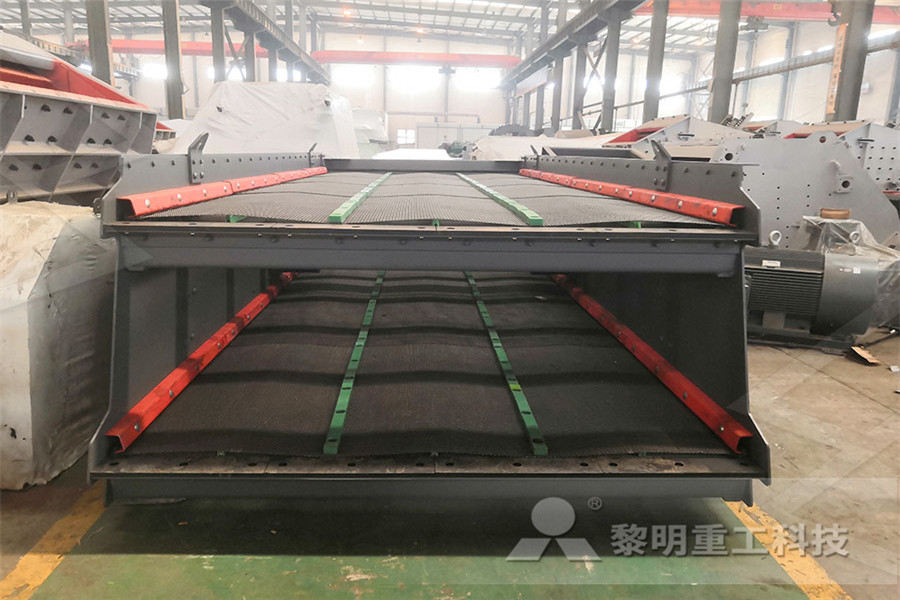

MINING EQUIPMENT NAMES List of mining equipment: types

Jun 30, 2019 The most common types of mining equipment vary depending on whether the work is being carried out above or below ground or mining for gold, metals, coal or crude oil From drilling machines to excavators, crushing and grinding equipment – the