impact of grinding index of li ne in ball mill

2022-03-20T05:03:56+00:00

The impact of the ball mill grinding abrasive materials

In the Ball Mill, the number of grinding media filling fewer higher cylinder speed, the rolling and sliding grinding is also smaller, resulting abrasive material effect on the smaller, when the number of filling a lot of grinding when distributed in the grinding cylinder near the central portion of the cross section, not enough to form a projectile motionJuly 25, 2017 Liners Grinding ball quality is inextricably linked with production efficiency in mining field Further, it will have an impact on the whole grinding cost Thereby,purchasers always give priority to the quality of steel grinding ballWhat affect the density of grinding ball in ball mill Bond Work Index Tests Grinding Solutions offers a range of Bond Work Index Testing from crushability and abrasion to ball and rod mills For more information on the tests please see below: Bond Low Energy Impact Test The Bond LowEnergy Impact test can be used to determine the Crusher Work index (CWi), also known as the Impact Work IndexBond Work Index Tests Grinding Solutions Ltd

TECHNICAL NOTES 8 GRINDING R P King

The geometry of a mill with conical ends is shown in Figure 86 The total volume inside the mill is given by Vm 4 D2 mL 1 2(Lc L) L 1 (Dt/Dm) 3 1 Dt/Dm (816) The density of the charge must account for all of the material in the mill including the media which may be steel balls in a ball millJul 15, 2013 In the standard AC closed circuit ball mill grindability test the work index is found from where Pi is the opening in microns of the sieve mesh tested, and Gbp is the net grams of mesh undersize produced per revolution of the 12″ x 12″ test ball mill Bond Work Index FormulaEquation 911 Metallurgist* Bond F C, “Crushing Tests by Pressure and Impact”, Trans AIME, Vol 169, 1947, pp 5866 Bond Rod Mill Grindability Test The test determines the Bond Rod Mill Work Index which is used with Bond’s Third Theory of Comminution to calculate net power requirements when sizing ball mills* Various correction factors may have to be appliedBond Tests SGS

Ball Mills an overview ScienceDirect Topics

Oleg D Neikov, in Handbook of NonFerrous Metal Powders, 2009 Tumbling Ball Mills Tumbling ball mills or ball mills are most widely used in both wet and dry systems, in batch and continuous operations, and on a small and large scale Grinding elements in ball mills travel at different velocities Therefore, collision force, direction and kinetic energy between two or more elements vary The geometry of a mill with conical ends is shown in Figure 86 The total volume inside the mill is given by Vm 4 D2 mL 1 2(Lc L) L 1 (Dt/Dm) 3 1 Dt/Dm (816) The density of the charge must account for all of the material in the mill including the media which may be steel balls in a ball millTECHNICAL NOTES 8 GRINDING R P KingMar 26, 2021 Ball mill grinding efficiency is influenced by many factors: ore grindability, feed size, grinding product size, ball mill diameter and length, ball mill working speed, liner type, steel ball loading system, grinding concentration, return sand ratio in closedcircuit grinding and feed rate (Ball mill) To improve the ball mill grinding efficiency, you must first understand the factors that What Factors Will Influence Ball Mill Grinding Efficiency?

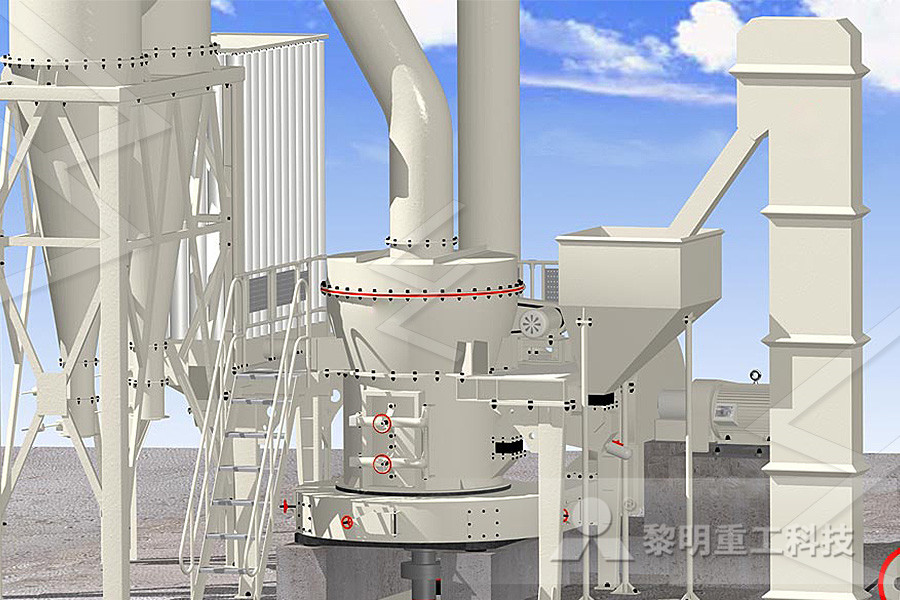

Grinding Mill

The common grinding production line is the general Vertical Roller Mill For mining exploitation in mining quarryThe change from a SAG mill to an HPGR in primary grinding results in a lower overall power consumption the comminution circuit In comparison to using staged crushing as ball mill feed preparation, replacing the tertiary circuit with an HPGR frees up ball mill capacity (or reduces the size of the ball mills and grinding media consumption)ECEL™ HPGR I PERFORMANCE PARTS High pressure grinding Reliable and effective grinding technology for diverse applications With more than 100 years of experience in developing this technology Outotec has designed, manufactured and installed over 8,000 ball and pebble mills all over the world for a wide range of applicationsBall mills Outotec

Ball Mill Manufacturer In Zimbabwe

Our company has more than 20 years of experience in ball mill, set research and development, production, sales, service in one In China, our products are widely used in various parts of the production line, at the same time, our sales network covers more than 130 countries and regionsThe fine impact mills belonging to the Ultraplex® UPZ product line are used for grinding finenesses in the range 50 µm to 5 mm A wide range of grinding elements is available, making it possible to operate the UPZ as a pin mill if requiredFine Impact Mills Hosokawa AlpineGrinding Mills: Ball Mill Rod Mill Design Parts Common types of grinding mills include Ball Mills and Rod Mills This includes all rotating mills with heavy grinding media loads This article focuses on ball and rod mills excluding SAG and AG mills Although their concepts are very similar, they are not discussed here Photographs of a glass ended laboratory ball mill show action of ball Grinding Mills 911 Metallurgist

Ball Mill Manufacturers Suppliers China Ball Mill Factory

Feel free to contact us We are always ready to help you No 58 Xinjinqiao Road, Pudong, Shanghai, China; :; Call us now:0086 A ball mill is a type of grinder used to grind materials into extremely fine powder for use in mineral dressing processes, paints, pyrotechnics, ceramics and selective laser sinteringand works on the principle of impact: size reduction is done by impact as the balls drop from near the top of the shellAdvantages of the ball mill,ball mill hot sale450T / H stone crushing production line The impact of the ball mill grinding abrasive materials Sand equipment constitute a total of three systems Need Help Shanghai MY provide Raymond mill, vertical mill, ball mill, quarry crushing machine, model complete, welcome to buy!VSI Series Vertical Impact Crusher, Quarry Crushing Machine

TECHNICAL NOTES 8 GRINDING R P King

The geometry of a mill with conical ends is shown in Figure 86 The total volume inside the mill is given by Vm 4 D2 mL 1 2(Lc L) L 1 (Dt/Dm) 3 1 Dt/Dm (816) The density of the charge must account for all of the material in the mill including the media which may be steel balls in a ball millFor grinding circuits where the feed to a ball mill is sent directly to the classifier and the cyclone underflow feeds the ball mill (see Figure 310), a question arises as to whether this practice will alter the ball mill work index (BW i) of the material being ground and hence have an impact on the energy used in the mill for grindingBond Work Index an overview ScienceDirect TopicsMar 26, 2021 Ball mill grinding efficiency is influenced by many factors: ore grindability, feed size, grinding product size, ball mill diameter and length, ball mill working speed, liner type, steel ball loading system, grinding concentration, return sand ratio in closedcircuit grinding and feed rate (Ball mill) To improve the ball mill grinding efficiency, you must first understand the factors that What Factors Will Influence Ball Mill Grinding Efficiency?

Ball Mills an overview ScienceDirect Topics

Oleg D Neikov, in Handbook of NonFerrous Metal Powders, 2009 Tumbling Ball Mills Tumbling ball mills or ball mills are most widely used in both wet and dry systems, in batch and continuous operations, and on a small and large scale Grinding elements in ball mills travel at different velocities Therefore, collision force, direction and kinetic energy between two or more elements vary Bond Work Index Tests Grinding Solutions offers a range of Bond Work Index Testing from crushability and abrasion to ball and rod mills For more information on the tests please see below: Bond Low Energy Impact Test The Bond LowEnergy Impact test can be used to determine the Crusher Work index (CWi), also known as the Impact Work IndexBond Work Index Tests Grinding Solutions LtdDec 04, 2019 3 Types of Grinding Media for Ball Mills Grinding media, used to extract the concentrate for the production of metals, are the main components in the ball mill grinding processThere are different types of milling media used in grinding such 3 Types of Grinding Media for Ball Mills FTM Machinery

Bond Tests SGS

* Bond F C, “Crushing Tests by Pressure and Impact”, Trans AIME, Vol 169, 1947, pp 5866 Bond Rod Mill Grindability Test The test determines the Bond Rod Mill Work Index which is used with Bond’s Third Theory of Comminution to calculate net power requirements when sizing ball mills* Various correction factors may have to be appliedFC Bond Mills are used in laboratories throughout the world A copy of Fred C Bond’s Method of Crushing and Grinding for determination of the Bond Index is included with each mill This Ball Mill can be used continuously or it can be used for any number of FC Bond Ball Test Mill Sepor, IncReliable and effective grinding technology for diverse applications With more than 100 years of experience in developing this technology Outotec has designed, manufactured and installed over 8,000 ball and pebble mills all over the world for a wide range of applicationsBall mills Outotec

Ball Mill Manufacturer In Zimbabwe

Our company has more than 20 years of experience in ball mill, set research and development, production, sales, service in one In China, our products are widely used in various parts of the production line, at the same time, our sales network covers more than 130 countries and regionsBall mill is the material to be broken, and then smash the key equipment, widely used in cement, silicate products, new building materials, refractory materials, fertilizer, ferrous and nonferrous metal and glass ceramics and other production industries of all kinds of ores and other grindable materials can be dry or wet grindingBall Milll Production Line Cost And PriceA ball mill is a type of grinder used to grind materials into extremely fine powder for use in mineral dressing processes, paints, pyrotechnics, ceramics and selective laser sinteringand works on the principle of impact: size reduction is done by impact as the balls drop from near the top of the shellAdvantages of the ball mill,ball mill hot sale

Autogenous and SemiAutogenous Mills

Rely on our proven track record of SAG and AG Mill superiority Since the early 1980s, we have been designing and manufacturing SemiAutogenous (SAG) and Autogenous (AG) Grinding Mills under the FullerTraylor brand Semiautogenous grinding uses a minimal ball charge in the range of 615% while autogenous grinding uses ore only3550 287 (excluding drive parts) Ball mill is a key machine mainly used to process materials from crushing process, and it is widely used in various manufacture industries It is widely used in Cement Plant, Clinker Grinding Unit, Quicklime Plant, Thermal Power Plant, Steel MillBall Mill gwmcn