Use Of Machine In Cement Factory

2018-12-28T20:12:05+00:00

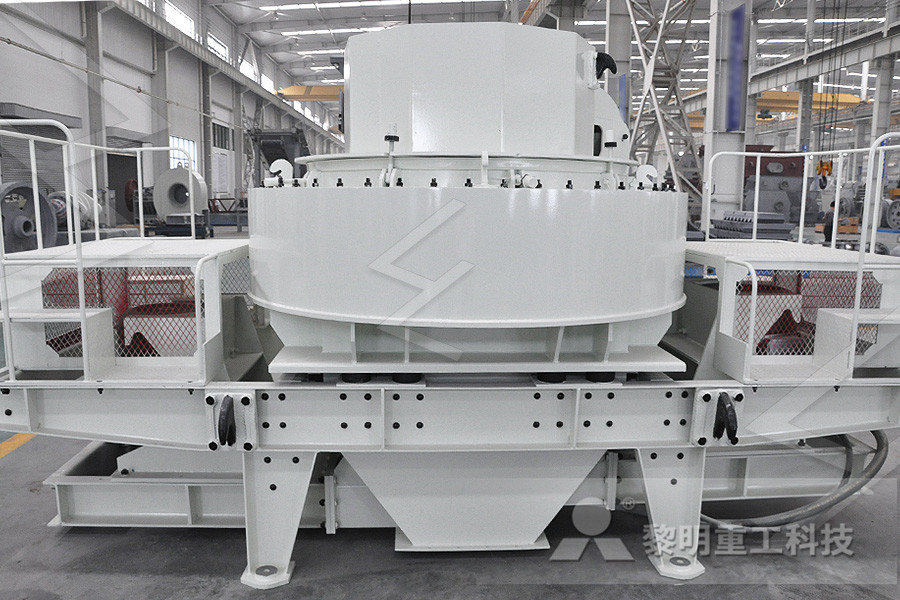

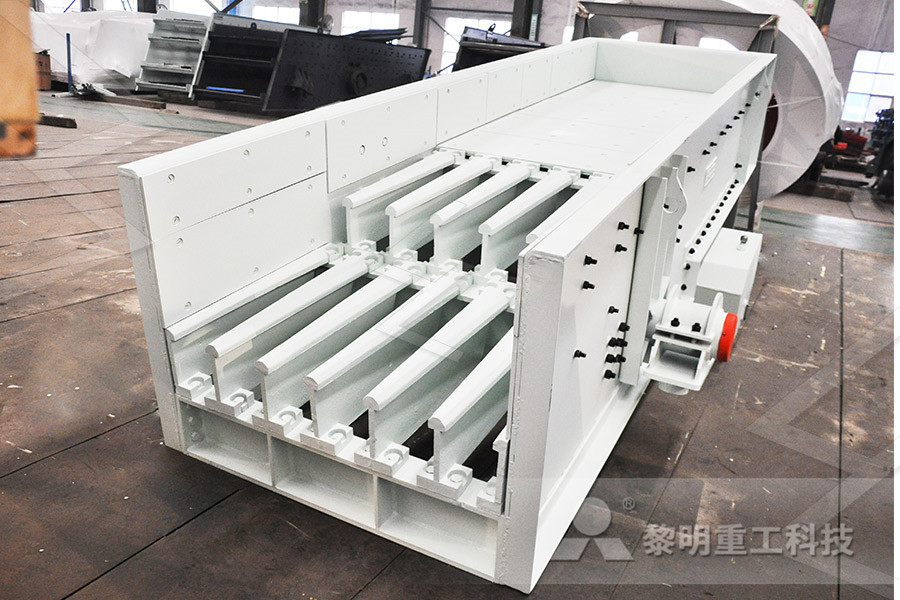

Cement Manufacturing Machine Cement Making Machine

The cement roller press is a new kind of cement mill It is usually used as a pregrinding system to replace some functions of the ball mill so that the output of the ball mill Sep 27, 2019 Cement kiln is used to make cement clinker, and it is the core equipment of cement production line; usually, apply for dry method cement production There are two main kinds of cement kiln to manufacture cement clinker One is the cement rotary kiln, and it is horizontal and can rotateCement Making Machines Cement PlantMachines used in a cement factory : Building materials equipment mainly includes cement production equipment, activated lime production equipment, etc, standardized production processes to ensure the smooth operation of equipment and processes, and ensure the interests of customersMachines used in a cement factory Mining Machinery Co, Ltd

What are equipments used in a cement plant Manufacturer

ball mill used for cement manufacturing process ball mill used for cement manufacturing process Cement Ball Mill is the equipment used to grind the The cement manufacturing process consists of many simultaneous and continuous operations using some of In the cement production line, we use cement crusher for cement crushing process, then we need cement mill for fine grinding stageOct 22, 2015 In various machines, conveyors, power plants, and in industries involving the production of cement, sugar, textiles, paper, etc Zero speed switches mainly use electromechanical, electronic, or magnetic proximity technologiesCement Plant Process and Instruments UsedNov 13, 2018 Appling Artificial Intelligence in a cement plant Given the company’s lack of experience, the management decided to partner, in the short term, with an external startup specialized in the realtime improvement of industrial processes through the application of Artificial Intelligence, Optimitive Machine learning could use these data to The future in cement manufacturing is here: Transforming

(PDF) Cement Manufacturing ResearchGate

Portland cement is b y far the most common type of cement in general use around the world This This cement is made by heating limestone (calcium carbonate) with other materials (such as cla y) toDec 18, 2020 To implement systematic 40 predictive maintenance, cement companies must first equip all critical machines with sensors that monitor inuse equipment conditions, such as vibration, temperature, and pressure They should then aggregate the data from these sensors into repositories, or Why Cement Producers Need to Embrace Industry 40Some Tips Need To Pay Attention When You Use Cement Brick Machine 1 If the vibratory power of the vibrator in cement brick making machine is insufficient, long period of brick production or the bricks are loose, reason is that the pressure of the lower die is too high, operator should gradually turn down the pressure of self regulating valve corresponding to the oil pipe of lower supporting Reliable Cement Block Machine Manufacturers Providing Good

Cement Making Machines Cement Plant

Sep 27, 2019 Except for the cement equipment we mentioned above, there are many other cement making machines applied for the cement plant In the real application, as a professional EPC cement plant project provider, AGICO Cement always provides a solution according to clients ’ needs, such as mini cement plant, VSK cement plant We also provide single Cement Plant Manufacturers Cement Plant We manufacture and supply all type of Cement Plant Machines and process equipment like Cement Plant Crushers, separators, vertical rollers, kiln and shells, bucket and chain belts etc The objective of Cement Plants Equipments is to improve the product quality The raw material used in cement plants are sand, clay, limestone, shale, and iron oreWhat are equipments used in a cement plant Manufacturer Nov 13, 2018 Appling Artificial Intelligence in a cement plant Given the company’s lack of experience, the management decided to partner, in the short term, with an external startup specialized in the realtime improvement of industrial processes through the application of Artificial Intelligence, Optimitive Machine learning could use these data to The future in cement manufacturing is here: Transforming

Concrete plant Wikipedia

Concrete plant use the control system to control the working of the machine concrete batch plants employ computer aided control to assist in fast and accurate measurement of input constituents or ingredients With concrete performance so dependent on accurate water measurement, systems often use digital scales for cementitious materials and aggregates, and moisture probes to measure Portland cement is b y far the most common type of cement in general use around the world This This cement is made by heating limestone (calcium carbonate) with other materials (such as cla y) to(PDF) Cement Manufacturing ResearchGateCement plant is necessary for cement production, mainly consist of a series of cement equipment apply for preparation of cement raw materials, clinker production, and finished cement production, such as cement mill, cement crusher, rotary kiln, cement roller press, cement dryer, clinker cooler, cement silo, and related cement plant equipmentCement Plant, Cement Equipment Cement Plant Manufacturer

Industrial cleaning solutions for CEMENT INDUSTRY Clean

Dec 01, 2008 The sweeping machines can be provided with cabin for the driver to make it comfortable to work in the dusty and sunny environment A road sweeper /vacuum sweeper will be highly beneficial for any cement plant to maintain cleanliness inside the plant, housing colonies, packing areas, etc, and at mines and jettyMay 23, 2018 Mesebo UltraTech cement plant truck loadingMesebo Cement Factory YouTubeAGICO is an expert cement plant supplier We have a variety of cement plants for sale including mini cement plants, portland cement plants, etc We also supply rotary kilns and other cement plant equipment Our factory is equipped with a series of advanced manufacturing machines such as Φ8m vertical lathe, Φ10m gear hobbing machine, 8m Cement Plant for Sale Cement Plant Equipment Design

(PDF) OCCUPATIONAL HEALTH AND SAFETY IN CEMENT INDUSTRY

Results Significant reductions were observed in pulmonary function parameters of cement factory workers compared to controls (FVC 403 vs 465 L in controls; FEV1 306 vs 395 L in controls; p The factory, located just outside of Barcelona, was a WWIera pollution machine that had closed down, and came with many repairs to be done when Ricardo Bofill and his team purchased it After years of partial deconstruction, the determined architect proceeded to lace the exterior of the property with vegetation, and furnish the interior as a Architect Turns Old Cement Factory Into His Home, And The Mini cement plant is also called small cement plant, which is composed of a furnace shell, a support unit, a support unit thrust, a driving unit, a movable kiln head, kiln tail sealing device, a combustion device, etc Mini cement plant also has other namMini Cement Plant,Small Cement Plant,Cement Mini Plant

beton cement factory machine

Concrete plant use of machines in cement factory a concrete plantalso known as a batch plant or batching plant or a concrete batching plantis equipment that cement plant great wall corporation great wall is the professional manufacturer of cement machinery with the production experience for more than a half of centuryget priceThe cement industry is an industry with serious dust pollution, the dust below 10 microns that it produces accounts for about 90% As cement equipment, the ESP electric precipitator is often set behind the cement kiln and other production processes, which is the essential equipment for cement plantsESP Electrostatic Precipitator Cement Plant Machinery Cement milling is the largest user of electric power on a cement plant, and because they can easily be started and stopped, it often pays to operate cement mills only during "offpeak" periods when cheaper power is available This is also favourable for electricity Cement mill Wikipedia

Concrete plant Wikipedia

Concrete plant use the control system to control the working of the machine concrete batch plants employ computer aided control to assist in fast and accurate measurement of input constituents or ingredients With concrete performance so dependent on accurate water measurement, systems often use May 25, 2017 Before we understand the working or operation of a concrete batch plantIt is important to understand the basic components and structure of a batching plantWe have mobile concrete plants installations in Philippines’s city like: Bulacan, Cavite and PampangaIt is a machine that combines various ingredients like aggregates, sand, water, cement How does a concrete batch plant work Operation of Crusher Machine Used In Cement Factory Cement can be not only hardened in the air but also better hardened in the water in which it will maintain and develop strength so cement is kind of cementitious material which will be of stronger hardness in water cement mill is used for cement grinding cement which machine is used for cement

Cement plant motors up to 13,8kV and 20000 kW

Cement plant motor manufacturing is one of our main product focuses Cement mills, fans, shredders in the production of cement, particularly large and efficient motors are required for the most diverse processes MENZEL offers individual motor solutions for all applications in the cement About products and suppliers: 142,062 cement manufacturing machine products are offered for sale by suppliers on Alibaba, of which cement making machinery accounts for 4%, mine mill accounts for 1%, and multifunction packaging machines accounts for 1%cement manufacturing machine, cement manufacturing machine The digital twin allows cement companies to mirror the entire production process through a digital model—a “twin” of the plant’s physical assets, processes, and systems—and use artificial intelligence (AI) and machine learning to optimize it Dozens of variables come into play in the cement production process, from the qualiWhy Cement Producers Need to Embrace Industry 4

Industrial cleaning solutions for CEMENT INDUSTRY Clean

Dec 01, 2008 The sweeping machines can be provided with cabin for the driver to make it comfortable to work in the dusty and sunny environment A road sweeper /vacuum sweeper will be highly beneficial for any cement plant to maintain cleanliness inside the plant, housing colonies, packing areas, etc, and at mines and jettyCement plant flue gas has a relatively high CO2 concentration; typically about 25 mol% compared to about 14% for a coal fired power plant The post combustion solvent scrubbing processes that are being developed for CO2 capture in coal fired power plants would in principle be suitable for use in cement CO CAPTURE IN THE CEMENT INDUSTRYResults Significant reductions were observed in pulmonary function parameters of cement factory workers compared to controls (FVC 403 vs 465 L in controls; FEV1 306 vs 395 L in controls; p (PDF) OCCUPATIONAL HEALTH AND SAFETY IN CEMENT INDUSTRY

Cement Factory Cost How Much Does It Cost To Start A

May 14, 2020 Cement factory machine; Cement plant manufacturer; Daily output; Enterprise competition; Other factors; Here is some details about element involved in cement factory cost: Cement factory machines As we all know, the cement production line is made up of various types of cement equipment, the cement factory cost depends on the cement factory A plant or a piece test Whether you are looking for an entire cement plant or a single piece of equipment, we are the premium supplier For new plants, we cover everything from evaluating initial quarry samples through to ongoing operation and maintenance servicesPremium solutions for the cement industryUnderstanding the advanced sensing and data analytics allows cement plant managers to make better decisions about the operation The ability to work with data is opening significant opportunities for process improvements in cement production One example is conditionbased maintenanceDigitalisation in the cement production process

Dzata Cement projects annual production of 3m tonnes

May 10, 2021 The first private sector wholly Ghanaianowned cement factory, Dzata Cement, is projecting to produce about three million tonnes of cement for