Minerals Low Capacity Grinding Mills

2019-10-03T10:10:40+00:00

Mineral Grinding Mills Thomasnet

Custom manufacturer of grinding mills for minerals Grinding mills are available in various models with specifications including 26 in x 30 in x 44 in to 80 in x 89 in x 50 in dimension, 011 cu ft to 25 cu ft hopper capacity, 78 sq in to 840 sq in screen area, 10 cfm to 750 cfm air flow, 21,000 ft/minute hammer tip speed Vmvertical grinding millVm series vertical grinding mill is a kind of large scale powder mill which is designed specially to solve the problems of low capacity and high consumption of industry millsWith a decade of research of mills vertical grinding mill is designed and manufactured based on our advanced design idea in combinationminerals low capacity grinding millsSepro Tire Drive Grinding Mills are a reliable solution for small and medium capacity grinding applications and are suitable for ball, rod and pebble charges Sepro Grinding Mills come complete with a Variable Frequency Drive (VFD) package which allows you to fine tune the operation of the grinding mill based on the charge and mining application No auxiliary drive is required to perform Tire Drive Grinding Mills Mineral Processing Equipment

SEPRO TYRE DRIVE GRINDING MILLS Sepro Mineral Systems

Sepro Tyre Drive Grinding Mills are a reliable solution for small and medium capacity grinding applications, and are suitable for Ball, Rod and Pebble charges Mills come complete with a variable frequency drive (VFD) package which allows you to fine tune the operation of the mill based on the charge and application No auxiliaryEarly mineral processing techniques employed the use of grinding mills as the first phases of liberating and isolating desirable minerals from gangue In the early phases it was also recognized that some form of size classification associated with the grinding mill would allow for more efficient operation of these grinding mills WeIMPLEMENTING STRATEGIES TO IMPROVE MILL CAPACITY Feb 17, 2019 Who We Are Founded in 1987, ZJH is mainly focus on producing and supply crushers,ore grinding equipment, mineral beneficiation equipment and laboratory and pilot equipment for Mines and Mineral Beneficiation Plants Our aim is to work together with the Mining and Mineral Processing Industry for helping to carry on the production technical innovation, to reduce the Ball Mills for Mining and Mineral Processing Industry

FCB Emill Fives in Cement Minerals

Low maintenance Thanks to a bed material grinding concept, the vertical FCB Emill offers power consumption reduced by 50% compared to the ball mill for coal grinding Customer benefitsdesirable minerals has consisted of grinding mills In the early phases it was also required very little space, provided high capacity and came with relatively low capital costs For these reasons and the increased demand for refined minerals, processing plantsINCREASING THE CAPACITY OF THE GRINDING CIRCUITS The grinding operation in a mineral processing facility typically consumes the majority of the energy used In addition to energy, these mills consume special steel rods or balls as well as the steel mill linings Combining all of these factors we see why grinding is one of the highest costs involved in mineral processing Keeping these costs inImplementing strategies to improve mill capacity and

AMIT 135: Lesson 6 Grinding Circuit – Mining Mill Operator

Grinding media is grinding feed; High capacity (short retention time) Sensitive to feed composition (critical size material) SemiAutogenous Grinding (SAG) Mill Wet or dry; Higher capacity than AG mill grinding; Primary, coarse grinding (up to 400 mm feed size) Grinding media is grinding feed plus 412% ball charge (ball dia100 125 mm) High Sepro Tire Drive Grinding Mills are a reliable solution for small and medium capacity grinding applications and are suitable for ball, rod and pebble charges Sepro Grinding Mills come complete with a Variable Frequency Drive (VFD) package which allows you to fine tune the operation of the grinding mill Tire Drive Grinding Mills Mineral Processing EquipmentSince our inception in 2001, we have been engaged in manufacturing, exporting and supplying top grade Media Mill For Nano GrindingManufactured with the use of qualitychecked components and ultramodern techniques, this mill is widely used for grinding Nano Grinding Mill Media Mill For Nano Grinding Exporter

LM Vertical Mill – Stone Crushers Grinding Mills for

LM Vertical Mill integrates crushing, drying, grinding, classifying and conveying together, and it is specialized in processing nonmetallic minerals, pulverized coal and slag Its coverage area is reduced by 50% compared with ball mill, and the energy consumption is saved by 30%40% similarlySepro Tyre Drive Grinding Mills are a reliable solution for small and medium capacity grinding applications, and are suitable for Ball, Rod and Pebble charges Mills come complete with a variable frequency drive (VFD) package which allows you to fine tune the operation of the mill based on the charge and application No auxiliarySEPRO TYRE DRIVE GRINDING MILLS Sepro Mineral Ore ball mill sometimes called ore grinding mill, is generally used in mineral processing concentrator, processing materials include iron ore, copper ore, gold ore, molybdenum ore and all kinds of nonferrous metal oreThe core function of the ore ball mill is to grind the materials, and also to separate and screen different mineral materials, and to separate the tailings, which is very Buy Ore Ball Mill for Mineral Processing Iron Gold Ore

IMPLEMENTING STRATEGIES TO IMPROVE MILL CAPACITY

Early mineral processing techniques employed the use of grinding mills as the first phases of liberating and isolating desirable minerals from gangue In the early phases it was also recognized that some form of size classification associated with the grinding mill would allow for more efficient operation of these grinding mills WeGKLM vertical grinding mill is one advanced powder making mill through our engineer research and experience It is ideal equipment for superfine milling industry which integrated with crushing, drying, grinding and collecting It is widely used in cement, power, metallurgy, chemical, nonmetallic mineralsVertical Grinding Mill, Vertical Roller Mill Powder Making desirable minerals has consisted of grinding mills In the early phases it was also required very little space, provided high capacity and came with relatively low capital costs For these reasons and the increased demand for refined minerals, processing plantsINCREASING THE CAPACITY OF THE GRINDING CIRCUITS

FCB Emill Fives in Cement Minerals

Low maintenance Thanks to a bed material grinding concept, the vertical FCB Emill offers power consumption reduced by 50% compared to the ball mill for coal grinding Customer benefitsThe grinding operation in a mineral processing facility typically consumes the majority of the energy used In addition to energy, these mills consume special steel rods or balls as well as the steel mill linings Combining all of these factors we see why grinding is one of the highest costs involved in mineral processing Keeping these costs inImplementing strategies to improve mill capacity and 47th ©Annual Canadian Mineral Processors Operators Conference , Ottawa, Ontario, January 2022, 2015 INTRODUCTION Conventional low throughput grinding options, consisting of multistage crushing followed by rod and ball mills, have almost become obsolete in the move to Orway Mineral Consultants Canada Ltd Mississauga, ON

Evolution of Laboratory Mills and Grinders Lab Manager

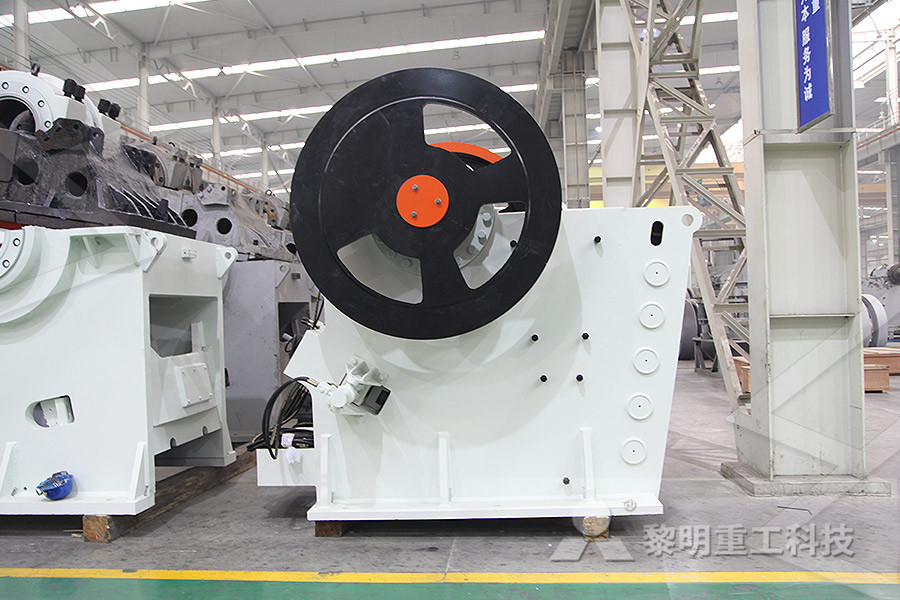

Around 1500 AD, the grinding of minerals was revolutionized when high demand for metals led to the development of waterdriven stamp mills for grinding large volumes of pebbles into small particles At this time, stamp mills were developed in which the pebbles were shattered by impact from a Crushing of Ore and Minerals purpose of the primary crusher is to reduce the ROM ore to a size amenable for feeding the secondary crusher or the SAG mill grinding circuit The ratio of reduction through a primary crusher can be up to about 8:1 Feed: For low capacity applications, use jaw crusher and hydraulic hammer for oversize Rule AMIT 135: Lesson 5 Crushing – Mining Mill Operator TrainingAug 07, 2020 HCH Ultrafine Grinding Mill for Mineral Powder Production 16:08; HCM; HCH ultrafine grinding mill is designed for high throughput and fine pwoder The product fineness can reach 4003000 mesh, it is a new ultrafine grinding mill integrating grinding, grading, conveying, secondary powder selection and finished product packaging in HCH Ultrafine Grinding Mill for Mineral Powder Production

Tire Drive Grinding Mills Mineral Processing Equipment

Sepro Tire Drive Grinding Mills are a reliable solution for small and medium capacity grinding applications and are suitable for ball, rod and pebble charges Sepro Grinding Mills come complete with a Variable Frequency Drive (VFD) package which allows you to fine tune the operation of the grinding mill Sepro Tyre Drive Grinding Mills are a reliable solution for small and medium capacity grinding applications, and are suitable for Ball, Rod and Pebble charges Mills come complete with a variable frequency drive (VFD) package which allows you to fine tune the operation of the mill based on the charge and application No auxiliarySEPRO TYRE DRIVE GRINDING MILLS Sepro Mineral Early mineral processing techniques employed the use of grinding mills as the first phases of liberating and isolating desirable minerals from gangue In the early phases it was also recognized that some form of size classification associated with the grinding mill would allow for more efficient operation of these grinding mills WeIMPLEMENTING STRATEGIES TO IMPROVE MILL CAPACITY

Limestone HCH Ultrafine Grinding Mill

The HCH ultrafine grinding mill grinding is ideal for highprecision grinding of mineral ores, the fineness can reach 0040005mm Robust design and construction easily process large, toughtogrind materials to ultrafine powders The added capability of angular grinding further enhance grinding capability and productivityCapacity Range: 200 kg/hr 5 mt/hr Steel: We are engaged in manufacturing and supplying of the one of finest quality Wet Grinding Mill used for mineral 5microns products The product is fabricated using finest grade raw materials under stringent supervision of our team of experts, ensures excellent results These low cost machines are Grinding Mill Micronizing Ball Mill Exporter from VadodaraLow maintenance Thanks to a bed material grinding concept, the vertical FCB Emill offers power consumption reduced by 50% compared to the ball mill for coal grinding Customer benefitsFCB Emill Fives in Cement Minerals

Ten Ways to Improve the Grinding Efficiency of Your Ball Mill

Apr 22, 2019 There are a lot of problems that most mineral processing plant meet when operating the ball mill, such as low grinding efficiency, low processing capacity, high energy consumption, unstable The grinding operation in a mineral processing facility typically consumes the majority of the energy used In addition to energy, these mills consume special steel rods or balls as well as the steel mill linings Combining all of these factors we see why grinding is one of the highest costs involved in mineral processing Keeping these costs inImplementing strategies to improve mill capacity and Crushing of Ore and Minerals purpose of the primary crusher is to reduce the ROM ore to a size amenable for feeding the secondary crusher or the SAG mill grinding circuit The ratio of reduction through a primary crusher can be up to about 8:1 Feed: For low capacity applications, use jaw crusher and hydraulic hammer for oversize Rule AMIT 135: Lesson 5 Crushing – Mining Mill Operator Training

Orway Mineral Consultants Canada Ltd Mississauga, ON

47th ©Annual Canadian Mineral Processors Operators Conference , Ottawa, Ontario, January 2022, 2015 INTRODUCTION Conventional low throughput grinding options, consisting of multistage crushing followed by rod and ball mills, have almost become obsolete in the move to May 10, 2019 When the concentration/ thickness is too low, the slurry flows quickly and the adhesion degree on the medium is low, which weakens the impact and grinding force grinding mill apply on the ore material Contrarily, high concentration, high adhesion may slow the flow speed, cause over grinding thus influence the production capacityFactors Influence Ore Grinding Mill Efficiency JXSC MiningMay 01, 2020 Too large a material ball ratio indicates too much ore in the mill, which might cause the mill to swell, and would affect the movement of grinding media and the circulation of ore in the mill, and also lower the mill capacity , With a filling rate of 32% and a material ball ratio of 07, 085, 10, and 115, the effect of the material ball Enhancing the capacity of largescale ball mill through

Introduction to Mineral Processing or Beneficiation

Jan 12, 2018 Autogenous and SemiAutogenous Mills Autogenous (AG) and SemiAutogenous (SAG) milling has seen increased use in recent years, especially in large mineral processing operations These mills typically have a large diameter relative to their length, typically in the ratio or 2 or 25 to 1 AG mills employ ore as the grinding mediawas not simulated This indicates that compared to ball mill circuit closed with cyclones for lowgrade ores where mineral density effect does not affect the overall classi cation ef ciency, the (PDF) Effect of Mineral Density for Milling Magnetite Ores