vertical milling equipment operation

2021-09-05T10:09:23+00:00

VERTICAL MILLING MACHINE OPERATION VCSHobbies

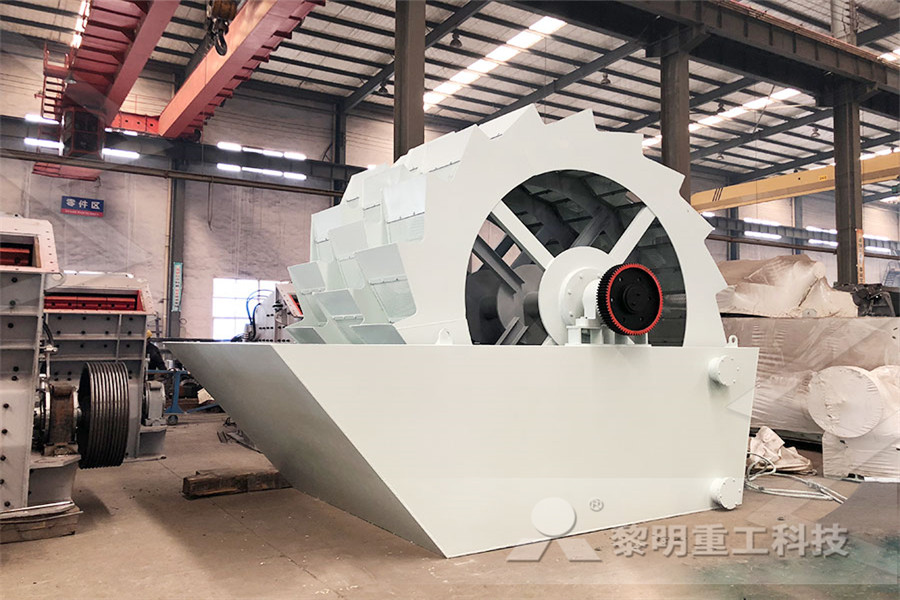

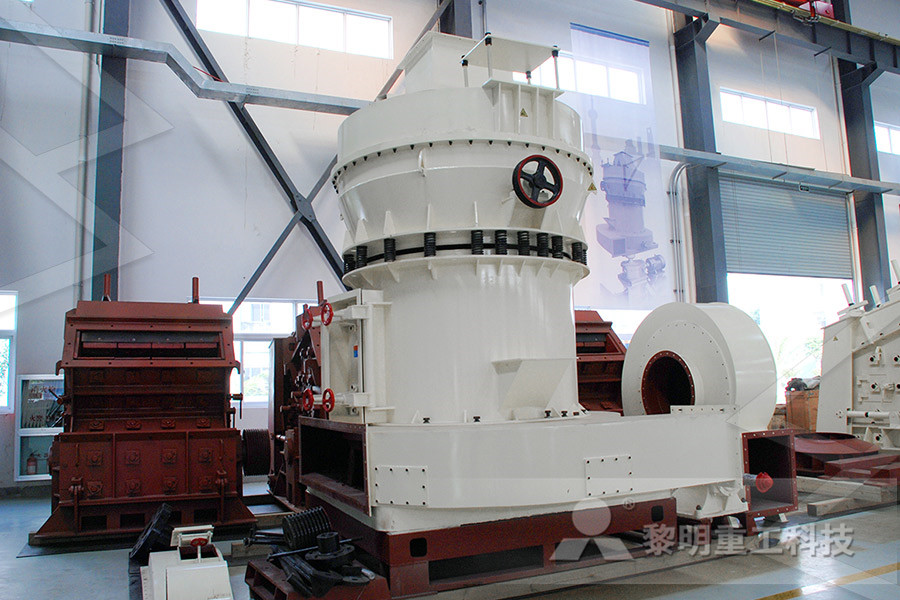

VERTICAL MILLING MACHINE OPERATION (Reprinted from the Sherline Assembly and Instruction Guide, Fourth Edition (1997) CAUTION! Read all operating instructions carefully before attempting any machining operations! Review Safety Rules for Power Tools before beginningVertical mill is a equipment that grinds materials by relative rolling of a grinding roller on grinding disc There are several aspects to the normal operation of the vertical mill: The material layer of Vertical mill The proper thickness of the layer and stable layer are basis for stable operationimportant operation tips for cement vertical millDec 01, 2018 Vertical Milling Machine: Vertical Milling Machine is one of the most used operation methodIn Vertical Milling Machine, there is a multipoint cutting tool called milling cutter this machine has vertical spindle which is perpendicular to the work pieceVertical milling machine: Working, Main Parts, Advantages

Introduction to the vertical Milling Machine YouTube

Jan 27, 2018 Mr Riggs explains the parts and functions of the vertical milling machineThis is Mill Skills, a multipart series to help you learn basic machine shop work Exclusive videos, drawings, models plans available on Patreon!https://wVertical Mill Tutorial 4 : Basic Milling Operations YouTubeThe side milling is the production of a flat vertical surface on the side of a work piece by using a sidemilling cutter The depth of cut is adjusted by rotating the vertical feed screw of the tableTypes of milling operation – AS PRECISION

MILLING MACHINE OPERATIONS HNSA

plain horizontal milling machine in that it is of the ram type; ie, the milling machine spindle is in a swivel cutter head mounted on a ram at the top of the column The ram can be moved in or out to provide different positions for milling operations (2) Ramtype Milling Machines (a) Description The ramtype milling machine is May 26, 2016 Angular milling: In this operation, surfaces which are at an angle to the axis of the cutter, is machined by the rotary cutter Milling machine can perform all other common operations like turning, facing, fillet making, chamfering, drilling, gear cutting, planning, slot cutting etc These are all main milling machine operationMilling Machine Operation mech4studyMar 05, 2004 The standard vertical milling machine has the cutter spindle mounted in a vertical position The head on most vertical milling machines may be swiveled, which readily permits the machining of angular surfaces The cutters used are of the end mill or shell end mill typesMilling Machine Operations

VERTICAL MILLING MACHINE OPERATION VCSHobbies

VERTICAL MILLING MACHINE OPERATION (Reprinted from the Sherline Assembly and Instruction Guide, Fourth Edition (1997) CAUTION! Read all operating instructions carefully before attempting any machining operations! Review Safety Rules for Power Tools before beginningVertical mill is a equipment that grinds materials by relative rolling of a grinding roller on grinding disc There are several aspects to the normal operation of the vertical mill: The material layer of Vertical mill The proper thickness of the layer and stable layer are basis for stable operation The material layer is too thick will lead to important operation tips for cement vertical millmilling head and milling machine spindle are properly adjusted vertically for operation The plain vertical machines are characterized by a spindle located vertically, parallel to the column face, and mounted in a sliding head that can be fed up and down by hand orINSTRUCTIONS HOW TO USE A MILLING MACHINE

Introduction to Machining: Milling Machine

Vertical Milling Machine is Most Common • Milling machines are very versatile They are usually used to machine flat surfaces, but can also produce irregular surfaces They can also be used to drill, bore, cut gears, and produce slots • The type of milling machine most commonly found in student shops is a vertical spindle machine with a Feb 24, 2019 Vertical Milling Machine is one of the most popular and most used operation methods In Vertical Milling Machine, there is a multipoint cutting tool called milling cutter this machine has a vertical spindle that is perpendicular to the workpiece In Vertical Milling Machine, the head is used to swiveled or it can be fixed This can move in Milling Machine: Operation, Types and parts of Milling plain horizontal milling machine in that it is of the ram type; ie, the milling machine spindle is in a swivel cutter head mounted on a ram at the top of the column The ram can be moved in or out to provide different positions for milling operations (2) Ramtype Milling Machines (a) Description The ramtype milling machine is MILLING MACHINE OPERATIONS HNSA

Milling Machine: Definition, Parts, Types, Operations

Milling machine another most important machine tool after the Lathe machine tool and drilling machine In this machine, a multipoint cutter is rotating against the workpiece and material removed from the workpiece accordingly In today’s article, you will learn about the definition, parts, types, and operation of a milling machine, also at the end of the article, I will add the Milling Machine Definition: The milling machine is a type of machine which removes the material from the workpiece by feeding the work past a rotating multipoint cutterThe metal removal rate is higher very high as the cutter has a high speed and many cutting edges It is the most important machine in the tool room as nearly all the operations can be performed on it with high accuracyMilling Machine: Definition, Parts, Operation, Application Mar 03, 2020 The Cam milling is the operation of production of cams in a milling machine by the use of a universal dividing head and a vertical milling attachment The axis of the cam can be set from zero to ninety degrees in reference to the surface of the table for obtaining different rise of the camMilling ( Machine ) Definition, Parts, Operations, Types

Horizontal vs Vertical Milling The Differences Explained

Apr 28, 2021 Bed Mill: A bed mill, on the other hand, moves the material perpendicular to the axisThe bed of the mill moves along the Y and Z axes and the spindle moves along the Xaxis, providing a full, 3axis range of movement The spindle movement, coupled together with the horizontal movement of the table enables milling of a variety of depths and shapesBriefly describe the process of locating the center of an existing hole on a vertical milling machine First, visually locate the spindle in the center of the hole by moving the table and saddle Mount a dial test indicator in the spindle and bring the point into contact with the work Next, place the spindle in neutral and rotate the indicator Machine Processes Section 6 unit 3 Flashcards QuizletJul 02, 2011 Bridgeport Milling Machine Operation and Maintenance Manual July 2, 2011 / 10 Comments / in Bridgeport , Free Download , Future Projects , Maintenance , rebuild , shop equipment / by mick I ran across this a while back, and had instance to use it today; it has some very nice plain explanations of machine maintenanceBridgeport Milling Machine Operation and Maintenance

Milling Machine: Parts, Types, Operations, Milling Cutter

Milling is the machining process in which the removal of metal takes place due to the cutting action of a rotating milling cutterIn a milling machine, the cutter is rotating due to workpiece is fed against itThis machine can hold more than one tool at a time The cutter rotates at high speed, and because of the many cutting edges, it removes metal at a very fast rateA Vertical Milling machine is a type of machine which can hold and rotates the spindle in the vertical orientation which can remove the material from the surface of a stationary workpiece Vertical Milling machine have longer and thinner cutting toolsMilling Machine: Definition, Parts, Types, Operations plain horizontal milling machine in that it is of the ram type; ie, the milling machine spindle is in a swivel cutter head mounted on a ram at the top of the column The ram can be moved in or out to provide different positions for milling operations (2) Ramtype Milling Machines (a) Description The ramtype milling machine is MILLING MACHINE OPERATIONS HNSA

Milling Machine: Operation, Types and parts of Milling

Feb 24, 2019 Vertical Milling Machine is one of the most popular and most used operation methods In Vertical Milling Machine, there is a multipoint cutting tool called milling cutter this machine has a vertical spindle that is perpendicular to the workpiece In Vertical Milling Machine, the head is used to swiveled or it can be fixed This can move in May 01, 2018 Introduction to Vertical Machining Vertical Machining has been around in its most basic form for more than 150 years Yet, it's still one of the newest forms of machining technology (turning/lathes is the oldest) The process of “milling” entails a rotating cutter, or drilling bit, and a movable work table, which the workpiece is affixed toThe Fundamentals of a Vertical Machining Center (VMC)Fig Number 2, Model K, sliding head vertical milling machine page 14 Fig 13 Angular milling operation on swivel head mach'ne VERTICAL KNEETYPE MILLING MACHINE The vertical kneetype machine differs from the horizontal only in the position of its spindle In some vertical spindle machines, Fig 12 the sliding verticalMilling Machine Practice Book 2

Different Types of Machining Operations and the Machining

May 22, 2021 As expected, the universal milling machine allows for both vertical and horizontal mounted cutting tools, making it one of the most complex and flexible milling machines available As with turning centers, milling machines capable of producing a series of operations on a part without operator intervention are commonplace and are often simply Keep floor around the milling machine free of oil and grease Use lifting equipment when appropriate to move heavy work to or from milling machines Refer to Materials Handling for more information Make sure the power is off before changing cutters Always stay at the machine when it is in operationMetalworking Machines Milling Machines : OSH AnswersMILLING MACHINE DO NOT use this machine unless you have been instructed in its safe use and operation and have been given permission PERSONAL PROTECTIVE EQUIPMENT Safety glasses must be worn at all times in work areas Long and loose hair must be contained Gloves must not be worn when using this machineSafety Operating Procedures Milling Machine

Bridge port milling machine manual The Curious Forge

on the machine you may have to block up the vise) Now crank the knee all the way up to the bottom of the head Position the table with X and Y cranks so the spindle nose goes into the vise jaws Crank the knee up so the bottom of the spindle sets inside the vise jaws Clamp the vise jaws onto the bottom of the spindle You will see that there isBriefly describe the process of locating the center of an existing hole on a vertical milling machine First, visually locate the spindle in the center of the hole by moving the table and saddle Mount a dial test indicator in the spindle and bring the point into contact with the work Next, place the spindle in neutral and rotate the indicator Machine Processes Section 6 unit 3 Flashcards QuizletINSTALLATION, OPERATION, MAINTENANCE, AND PARTS LIST SERIES I MILLING MACHINES Revised: May 21, 2010 Manual No M450A Litho in USA Part No M A0450 March, 2009SERIES I MILLING MACHINES

Contents

21 Horizontal Milling Machine 22 Vertical Milling Machine 3 Cutting Tools 31 Cutting Tools for Horizontal Milling Machine 32 Cutting Tools for Vertical Milling Machine 4 Industrial Applications 5 Milling Processes 51 Spindle Speed 52 Feed Rate 53 Depth of Cut 54 Direction of Cutter Rotation 6 Typical Milling Operations 61 Plain MillingIn an effort to provide you advantage and enlarge our business enterprise, we even have inspectors in QC Staff and assure you our greatest provider and item for Vertical Turret Milling Machine Operation Manual, Manufacturer Of Chinese Inclined Bed Cnc Lathe Manufacturers, Cnc Turning Lathe Manufacturer, Cnc Mini Lathe Supplier, While using the improvement of society and economy, our China Vertical Turret Milling Machine Operation Manual Sep 09, 2018 Operation of a Horizontal Milling Machine In contrast to vertical milling equipment, horizontal milling machines don’t use a fixed spindle Instead, they employ cutting heads similar to small circular saws that are mounted on a horizontal arbor In some cases, such as when the arbor stretches across the entire length of the bed, multiple An Overview of Vertical vs Horizontal Milling Precise Tool

Standard Operating Procedure (SOP) – Milling Machine

Nov 02, 2009 While operating the milling machine allow no one else to touch it Keep hands away from moving cutting tools Do not make measurements of the stock while the milling machine is powered Do not allow large quantities of chips to accumulate around the work piece or machine table After stopping the machine, use a brush or rag to remove all excess