mining and processing iron

2022-05-09T21:05:29+00:00

Iron Mining Process Minnesota Iron

Iron Mining Process From blasting to crushing to separation – more than 85% of the iron mined in the United States is mined in northeastern Minnesota to make our nation’s steelIron processing, use of a smelting process to turn the ore into a form from which products can be fashioned Included in this article also is a discussion of the mining of iron and of its preparation for smelting Iron (Fe) is a relatively dense metal with a Iron processing BritannicaMINING AND PROCESSING: Iron ore mining can be broadly divided into two categories namely 1) manual mining which is employed in small mines and 2) mechanized mining is suitable for large iron ore mines Manual mining method is normally limited to float ores and small mines Mining of reef ore is also being done manually on a small scaleIron Ore Mining Techniques Metal Extraction

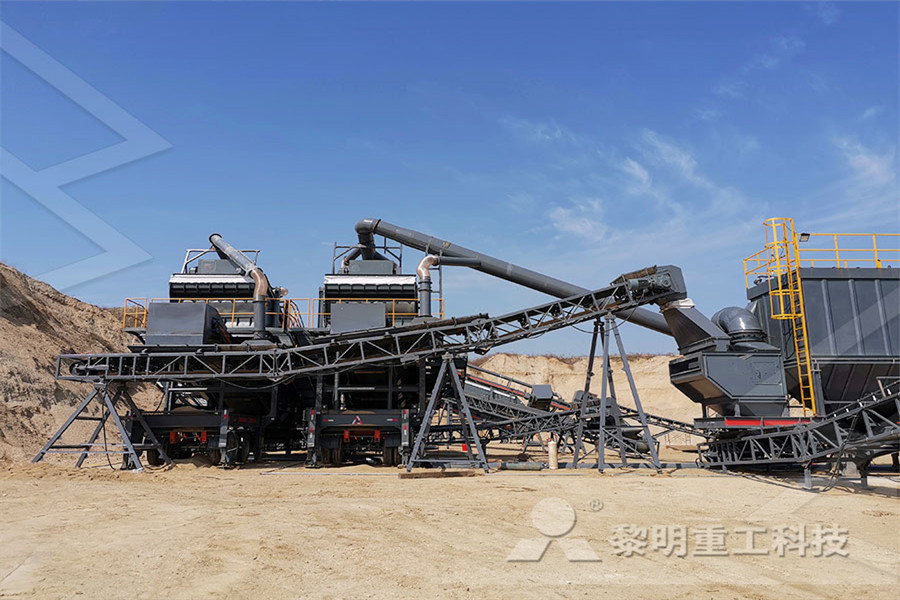

Mining and Processing Iron Ore Vulcan® Drying Systems

Vulcan Drying Systems has designed and built plants for clients processing up to 450 tons per hour Drying is an important step in the iron ore process, reducing shipping and storage costs, while making the material easier to handle As an essential ingredient in steel production, iron ore is the most commonly used metal in the worldMar 14, 2018 When the iron ore is extracted from the mine, it must undergo several processing stages Six steps to process iron ore 1 Screening We recommend that you begin by screening the iron ore to separate fine particles below the crusher’s CSS before the crushing stage A static screen is used to divert the fine particles for crushingThe Six Main Steps of Iron Ore Processing Multotec CanadaJun 01, 2015 Iron Ore Processing – From Ore to Steel Starting from the raw materials and going all the way to the finished product, our company handles coal and iron ore mining in order to provide a complete range of service offerings and steel productsIron Ore Mining and Processing

Environmental impact of iron ore mining Wikipedia

Iron ore is rock containing enough iron content, and in sufficient volume and accessibility to mining and transportation to be able to be economically mined Iron in ore iron is most commonly found in the form of magnetite (Fe3O4), hematite (Fe2O3), goethite (FeO(OH)), limonite (FeO(OH)n(H2O)) or siderite (FeCO3) Roughly 98% of iron ore on the global market is used in iron and steel production Common methods of extracting the iron ore consist of blasting, drilling, or general excavating, Most iroMining and Processing Iron Ore sales@vulcandryingsystems Iron Ore’s Composition Iron ores consist mostly of iron oxides and include magnetite, hematite, limonite, and many other rocks The iron content in these ores varies from as high as 70% to less than 20% The best grades of ore contain more than 60% ironMining and Processing Iron Ore Vulcan® Drying SystemsJan 01, 2015 The study used typical iron ore mining and processing operations in Pilbara, Western Australia, as a case study and covers the upstream part of the cradletogate life cycle of steel: the mining and processing of iron ore Transport of lump and fines to the shipping port was also included, as these mines are usually located some distance inland Life cycle assessment of iron ore mining and processing

ore mining and processing ResearchGate

Life cycle assessment of iron ore mining and processing 619 Many minerals contain iron, but the primary sources of iron ore minerals used to make iron and steel are hematite, magnetite Mining iron ore is a highvolume, lowmargin business, as the value of iron is significantly lower than base metals It is highly capital intensive, and requires significant investment in infrastructure such as rail in order to transport the ore from the mine to a freight ship [21]Iron ore WikipediaUS Iron is a world class counterparty to the global steel industry, conducting its own mining, processing, shipping, marketing and sales of high quality iron oxide ore US Iron LLC is a privatelyowned, USfocused iron oxide ore mining and reclamation company We have traded iron oxide ore domestically for over 10 years and in 2009/10 took US Iron Home

Mining and Processing the World’s Mostmined Minerals

Nov 13, 2018 Mining and Processing the World’s Mostmined Minerals By Chris Calam 11132018 The most recent edition of World Mineral Production, published by the British Geological Survey (BGS), reports that as of 2016, the five mostmined minerals in the world are coal, iron, bauxite, phosphorous rock, and gypsumJun 06, 2016 About Press Copyright Contact us Creators Advertise Developers Terms Privacy Policy Safety How YouTube works Test new features Press Copyright Contact us Creators Minnesota Iron Mining Process YouTubeMaterial adapted from: Hudson, TL, Fox, FD, and Plumlee, GS 1999 Metal Mining and the Environment, p 7,2027,3135,3839 Published by the American Geosciences Institute Environmental Awareness Series Modern mining operations actively strive to mitigate potential environmental consequences of extracting metals, and such operations are strictly regulated in the UnitedHow can metal mining impact the environment? American

Sukha Balka GOK (Mining and Processing Plant

Aug 12, 2020 Sukha Balka GOK (Mining and Processing Plant) Sukha Balka mines iron ore using the underground method at two mines: Yuvileyna (reserves of rich iron ore — 449 million tons) and Frunze (reserves of rich iron ore — 142 million tons)Apr 15, 2012 However, mining is not the only supplier of these raw materials Next to the primary mining industry a secondary mining industry is growing: ‘urban mining’ The existing stock of materials in the urban environment is recycled more and more 38% of iron input in the steel making process comes from scrapRecycling the Future of Mining The Business of MiningJun 21, 2018 Iron ore processing After the iron ore has been prepared by crushing and grinding during ore extraction, the ore is actually processed The aim of this is to reduce the undesirable high proportion of admixtures to a desired minimum in order to increase the iron content This is done by processes such as flotation or magnetic separation Iron ore mining and dressing tecscience

Iron Ore Processing Prominer (Shanghai) Mining

Based on the iron ore processing experience and necessary processing tests, Prominer can supply complete processing plant combined with various processing technologies, such as gravity separation, magnetic separation, flotation, etc, to improve the grade of TFe of the concentrate and get the best yieldiron processing: Mining and concentrating — Britannica Online Use of a smelting process to turn the ore into a form from which products can be fashioned Included in this article also is a discussion of the mining of iron and of »More detailedmining and processing of iron MiningMar 14, 2014 The process of mining consists of discovery of an iron ore deposit through extraction of iron ore and finally to returning the land to its natural state It consists of several distinct steps The first is discovery of the iron ore deposit which is carried out through prospecting or exploration to find and then define the extent, location and Mining of Iron Ores – IspatGuru

The Six Main Steps of Iron Ore Processing Multotec Canada

Mar 14, 2018 When the iron ore is extracted from the mine, it must undergo several processing stages Six steps to process iron ore 1 Screening We recommend that you begin by screening the iron ore to separate fine particles below the crusher’s Aug 24, 2016 INTRODUCTION TO MATERIALS – This is the first post on materials Iron ore and steel productionThe 6minute video explains the mining and processing of iron IRON ORE AND STEEL PRODUCTION YouTubeThe process of extracting iron from ore produces great quantities of poisonous and corrosive gases In practice, these gases are scrubbed and recycled Inevitably, however, some small amounts of toxic gases escape to the atmosphere A byproduct of iron purification is slag, which is produced in huge amountsHow iron is made material, manufacture, making, history

mining and processing of iron ore Mining

Iron ore – Wikipedia, the free encyclopedia Iron ore mining methods vary by the type of ore being mined There are four main types of iron See also: Mineral processingLowergrade sources of iron ore »More detailedJun 06, 2016 About Press Copyright Contact us Creators Advertise Developers Terms Privacy Policy Safety How YouTube works Test new features Press Copyright Contact us Creators Minnesota Iron Mining Process YouTubeMining, Mineral Processing and Metallurgy Quick and efficient separation of solids is a key process parameter in the mineral processing industry Daiichi offers DK SET brand of high performance flocculants for all process applications of solidliquid separation for Iron Ore, Zinc Copper, Steel, Gold, Uranium, Alumina, etcMining, Mineral Processing and Metallurgy

Mining and Processing Plants energosteel

Metinvest is the largest in Ukraine and one of the largest CIS producers of iron ore raw materials and steel By results of 2013 Metinvest occupies the 25th place among the world largest steel companies according to the World Steel Association Energosteel company cooperates with all mining and processing enterprises of the holdingAug 12, 2020 Sukha Balka GOK (Mining and Processing Plant) Sukha Balka mines iron ore using the underground method at two mines: Yuvileyna (reserves of rich iron ore — 449 million tons) and Frunze (reserves of rich iron ore — 142 million tons)Sukha Balka GOK (Mining and Processing Plant Jun 10, 2016 Screening is the passing of material through definite and uniform apertures is the only true and accurate means of grading to a required particle size Air separation and hydraulic classification depend upon gravity and particle shape, and result in the segregation and retention of material of higher specific gravity and lower surface area irrespective of sizeScreening 101 Mineral Processing Metallurgy

The Environmental Impact of Mining (Different Mining

May 27, 2020 Mining remains an essential and growing part of the modern industry By some estimates, it makes up nearly 45% of the total global economy, and mineral production continues to increase as demand for raw materials grows around the world However, many mining techniques still in use can have serious impacts on both the mining site itself and the surrounding environmentJul 20, 2015 Iron Ore: Mineralogy, Processing and Environmental Issues summarizes recent, key research on the characterization of iron ores, including important topics such as beneficiation (separation and refining), agglomeration (eg, production of pellets or powders), blast furnace technology for smelting, and environmental issues relating to its productionIron Ore 1st EditionKenyan Iron Ore: Mining and prospects of processing Prof S M Maranga* and Alvin Kiprono Bett* and Kyalo Ndeto* and Gilbert Bett** *Jomo Kenyatta University of Agriculture and Technology (Department of Mechanical Engineering) **Wanjala Mines Abstract Industrialization is one of the economic pillars in the Kenya Vision 2030 thus iron and steel will be prominent in the industrialization process(PDF) Kenyan Iron Ore: Mining and prospects of processing

Major Mines Projects Sino Iron Mine

25 years (as of Jan 1, 2016) CITIC Pacific Mining’s (CPM) Sino Iron project at Cape Preston is located 100km south west of Karratha, in Western Australia’s resource rich Pilbara region The largest magnetite mining and processing operation in Australia, downstream processing operations currently consist of six production linesToday, most of our iron ore production (about 60%) is through dry processing The natural moisture processing is used at Carajás and Serra Leste mines, at S11D Eliezer Batista complex, in Pará, and at several plants in Minas GeraisDry Processing Vale