Jaw Crusher Equipment Super Large Size Jaw Crusher

2020-07-19T21:07:35+00:00

Jaw Crushers McLanahan

As a rule, Jaw Crushers have a 6:1 or 8:1 ratio for crushing material Still using the 32 x 54 Jaw Crusher example, the top size of the feed entering the crushing chamber has to follow the F80 rule that 80% of the top size feed material is smaller than the gape Jaw crushers are typically used as primary crushers because they can take large and variable sized feed material, so the original feed won’t have to be blasted down to a fine size jaws are designed to be significantly more reliable and have lower wear rates, maximizing production and minimizing wear partsJaw Crusher The PROS and CONS of JAW CRUSHERS and IMPACT CRUSHERS * All photos, specifications, and/or data is approximate and subject to change without notice Information provided on this website is general and for the purpose of presenting an overview of the company, its abilities, and productsJAW CRUSHERS RR Equipment Company

Jaw Crusher Eriez Lab Equipment

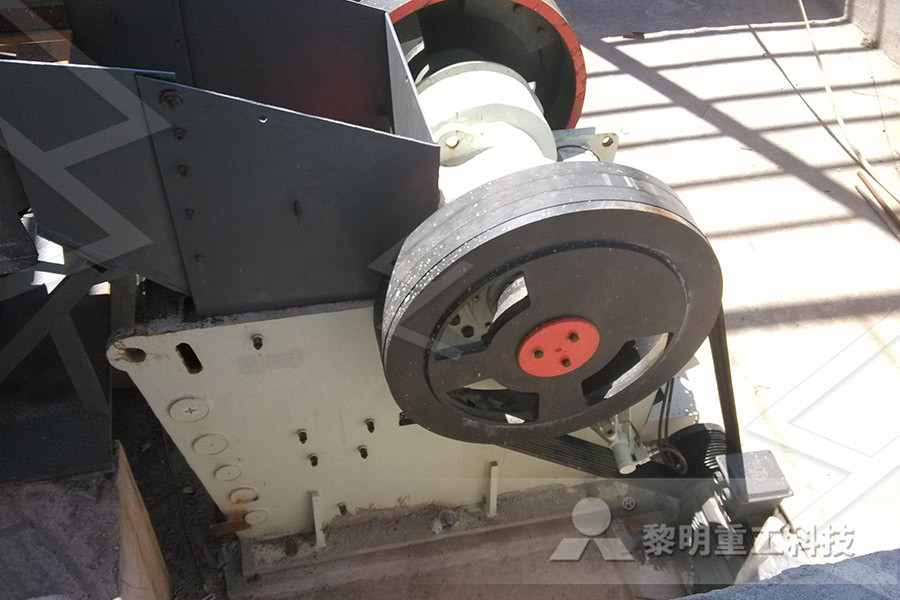

150 x 250 (6" x 10") Jaw Crusher with: • 55 kW Electrical motor • Starter with overload protection • Cast Iron construction with Mild Steel base frame • Vbelt driven with pulley flywheel guard Standard Guards • Reversible Manganese Steel Jaws Inlet Size: 6" x 10" (150 x 250 mm) Maximum Feed SizeJaw crushers reduce large rocks or ore by means of compression Mechanical pressure is applied using the crusher’s two jaw; one is fixed while the other makes an eccentric movement There are also primary and secondary types of these crushers Jaw crushers are one of the most commonly preferred crushers due to their ability to crush all kinds Jaw Crushers MEKA Crushing Screening PlantsThe length from 1 to 7 cm depends on the crusher machine size Jaw crushers are supplied in sizes up to 1,600 mm (gape)×1,900 mm (width) For coarse crushing application (closed set~300 mm), capacities range up to 1200 tph Jaw Crusher Wear PartsJaw Crusher Primary Crusher in Mining Aggregate JXSC

Industrial Jaw Crushers For Sale Affordable Crushing

Jaw crusher This is rock crushing equipment that is mostly used for crushing rocks and materials that have a strength of less than 320MPa There are seven models of jaw crushers for sale available and the maximum feeding size ranges from 1251200mm and the discharge produced ranges from 10350mmJaw Crusher For Sale Aimix jaw crusher has capacity of 11100 t/h, the maximum feeding size is 1251200 mm We also support customized services It can be used for crushing various types of raw materials, includes: Granite, marble, basalt, limestone, quartz, river pebbles, iron ore, copper ore, etcJaw Crusher For Sale Aimix Crusher Screening Plant For Jaw crushers are typically used as primary crushers because they can take large and variable sized feed material, so the original feed won’t have to be blasted down to a fine size jaws are designed to be significantly more reliable and have lower wear rates, maximizing production and minimizing wear partsJaw Crusher

Jaw Crushers Mt Baker Mining and Metals

I bought a 10″ x 16″ jaw crusher from Mt Baker Mining in February 2014 for crushing concrete and demolition debris I have installed a 37 hp gasoline motor on the crusher so it is mobile and I can haul it on the back of my truck The jaw crusher Read MoreAs a rule, Jaw Crushers have a 6:1 or 8:1 ratio for crushing material Still using the 32 x 54 Jaw Crusher example, the top size of the feed entering the crushing chamber has to follow the F80 rule that 80% of the top size feed material is smaller than the gape openingJaw Crushers McLanahanThese crushers are amongst the most advanced and reliable in the market and are highly productive in a variety of applications Jaw crushers are typically used as primary crushers because they can take large and variable sized feed material, so the original feed won’t have to be blasted down to a fine sizeJaw Crusher Premiertrak 400X R400X

Jaw Crushers Telsmith

H2238 Jaw Crushers View More TelsmithHydraJawCrushers Hydraulic Chamber Clearing system with push button controls allows the crusher to start up in as little as 15 minutes Toggle tensioning system eliminates the need to adjust springs when changing the settingLump breakers are ideal most common deagglomeration applications, and where flowability is the goal Industrial hammer mills and jaw crushers are the size reduction equipment of choice for processing large, blocky and/or abrasive materials SchutteBuffalo offers an extensive line of lump breakers, industrial hammer mills, and jaw crushersB Series Industrial Jaw Crusher Schutte HammermillSuperabove PE600X900 jaw crusher Manufacturer: Superabove; Lab Jaw Crusher for Gold Mining and Stone Rock Crushing Jaw Crusher Brief Introduction Our stone crusher machine, a type of jaw crusher is widely used in mining, railway construction, water conservancy project, mUsed Lab Jaw Crushers for sale Retsch equipment more

Jaw Crushers by Pennsylvania Crusher TerraSource Global

Many types of crushers use rotating hammers and other crushing elements to reduce materials by impact, shear or attrition Jaw Crushers, however, crush by compression of the material between two opposing surfaces — the jaws Pennsylvania Crusher brand Jaw Crushers are available in both Double Toggle and Overhead Eccentric modelsThe ROCO R9R Jaw Crusher is designed uniquely with the recycling industry in mind with all the important things you need incorporated into our super design This game changing Dual powered 195 tonne The tracked jaw crusher has a whole host of extras, including full electric plugin facility, reverse crush and Pre screen to name a fewCRUSHERS Retec EquipmentCrushers include offers jaw crushers, hammermills, cone crushers, and roll crusher options, each with multiple models, and designed for performance on harder materials such as ores, minerals, coal, and rock Pulverizers efficiently reduce aggregate, mineral or coal sample particle sizes using grinding plates, hammermills, or centrifugal impactCrushers, Pulverizers Mills Gilson Co

Impact, Cone Jaw Crusher Equipment For Sale Kobe

Astro JawE Crusher Features of the Astro JawE Crushing Equipment Large Crushing Capacity with New “V” Chamber Design The newly designed “Vshape” crushing chamber ensures the Jaw Crushers ability to withstand large capacities of feed material, while Its reversible, corrugated jaw plates create a nonchoke configurationROCK CRUSHER OPERATING INSTRUCTIONS Models RC46 RC46T INTRODUCTION: The new RC46 Rock Crusher is a three stage crushing machine that can reduce a rock as large as 4 x 6 inches into powder in moments The first stage is a jaw crusher, that initially crushes the rock to a size of approximately 1/4 of an inchModels RC46 RC46TAug 01, 2019 The finished material is output by the conveyor If the material does not meet the specifications, it will continue to return to the impact crusher and break again Equipment configuration: PE400×600 jaw crusher + PF1010 impact crusher Customer feedback: The equipment is running stably and effectively, and the impact crusher runs well The 2 Types of Concrete Crushers

Jaw Crusher Working Principle 911 Metallurgist

May 06, 2021 A sectional view of the singletoggle type of jaw crusher is shown below In one respect, the working principle and application of this machine is similar to all type of rock crushers, the movable jaw has its maximum movement at the top of the crushing chamber, and minimum movement at the discharge pointThe motion is, however, a more complex one than the Dodge motion, being the As a rule, Jaw Crushers have a 6:1 or 8:1 ratio for crushing material Still using the 32 x 54 Jaw Crusher example, the top size of the feed entering the crushing chamber has to follow the F80 rule that 80% of the top size feed material is smaller than the gape Jaw Crushers McLanahanThese crushers are amongst the most advanced and reliable in the market and are highly productive in a variety of applications Jaw crushers are typically used as primary crushers because they can take large and variable sized feed material, so the original feed won’t have to be blasted down to a fine sizeJaw Crusher Premiertrak 400X R400X

Jaw Crushers Telsmith

H2238 Jaw Crushers View More TelsmithHydraJawCrushers Hydraulic Chamber Clearing system with push button controls allows the crusher to start up in as little as 15 minutes Toggle tensioning system eliminates the need to adjust springs when changing the settingJaw Crusher is widely used to crush various large stones, limestone, granite, basalt, river gravel, etc The highest antipressure strength of material to be crushed is 320MPa The jaw crusher is mainly used to crush hard and medium hard stones in stone mining, metallurgy industry, building material, highway, railway, stone industry, etcJaw Crusher Liming Heavy IndustryAug 01, 2019 The finished material is output by the conveyor If the material does not meet the specifications, it will continue to return to the impact crusher and break again Equipment configuration: PE400×600 jaw crusher + PF1010 impact crusher Customer feedback: The equipment is running stably and effectively, and the impact crusher runs well The 2 Types of Concrete Crushers

Crushers, Pulverizers Mills Gilson Co

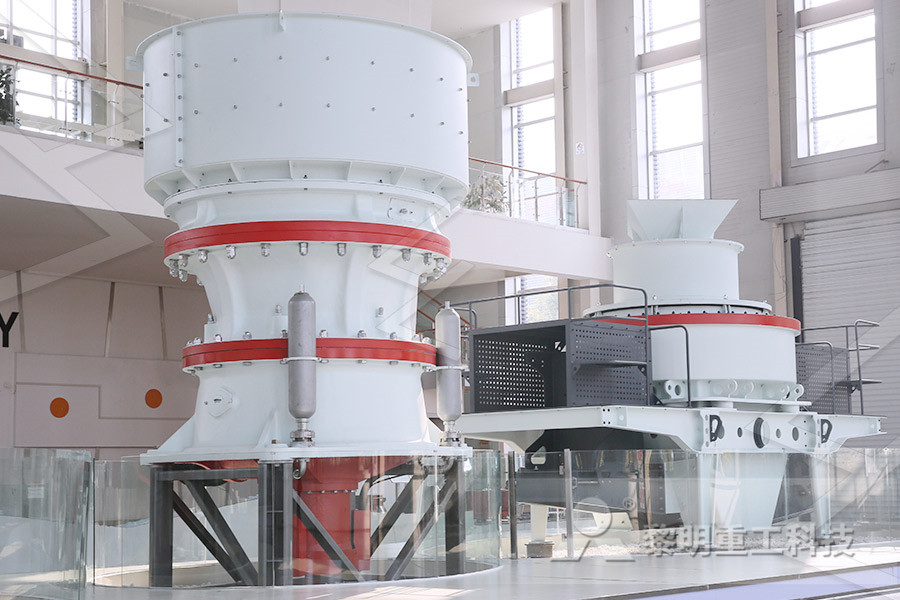

Crushers include offers jaw crushers, hammermills, cone crushers, and roll crusher options, each with multiple models, and designed for performance on harder materials such as ores, minerals, coal, and rock Pulverizers efficiently reduce aggregate, mineral or coal sample particle sizes using grinding plates, hammermills, or centrifugal impactFor instance, if the final size of your product only needs to be between 4 inches and 6 inches, a primary jaw or impact crusher can accomplish your goals However, you will likely require a much finer product, and that means incorporating up to three—or even four—stations with a variety of crusher typesTypes of Rock Crushers Quarry Crushing Equipment KemperApr 02, 2021 Its maximum size is 1070mm and capacity is 2760t/h; its product size is uniform and maximum discharging size is within 300mm; compared with jaw crusher, it can save 5% – 10% energy; It can be widely used in metal mine, metallurgy, chemical industry, building material and other largescale primary crushing materialSuper Capacity! NMS GC5065 Gyratory Crusher, You Deserve It

Crushers For Sale Equipment Trader

The three main types of crushers are the cone crusher, the jaw crusher, and the impact crusher Make sure you understand all of the differences between these kinds before choosing one for your project Regardless of which type of machine you choose, you should be businessIndustry Information Crushers Crushers are machines designed to reduce large waste materials for easier disposal or recycling One of the most common types of pulverizers, crushers are typically used to reduce the size of large rocks, changing them into more easilyhandled small rocks, rock dust or gravelCrushers are able to break apart or compress soft materials such as limestone Crusher Manufacturers Suppliers IQS DirectoryAs compared with traditional PE jaw crusher, the JC series jaw crusher has a completely improved crushing chamber, material, bearing standard, manufacturing technology, the frame is more robust and reliable Productivity is improved by 30%, while the production cost is reduced more than 20%Crushers Natus Mining Solutions NMS Africa

Mobile jaw crusher (Crawler type)

This is a new type of jaw crusher that has been optimized and designed from the aspects of structure, material selection, process and assembly Its structure is unique light weight, reliable operation, simple operation, large crushing ratio and high capacity,which is the preferred equipment for crushing various hard and strong abrasive rock 5 Jaw crusher has simple structure, reliable performance and low operating cost 6 Jaw crusher is a kind of energy saving equipment Single machine can save 15% ~ 30% energy and whole system saves more than doubled energy 7 Discharging opening has large adjusting range, so your different requirements can be satisfied 8 Low noise and Jaw CrusherAQS Heavy Machinery crushercrusherJaw Crushers are often used as the primary crusher of crushing process HJ series high efficiency jaw crusher is a new modern generation crusher designed by Liming, based on jaw crusher and combined with the design concept of high inputhigh output, integrating the characteristics of HJ Jaw Crusher, High Efficiency Jaw Crusher, jaw crusher