Composition Of Gypsum In Ball Mill

2022-02-04T07:02:30+00:00

ball mill grinding media chemical composition

ball mill grinding media chemical composition T02:10:16+00:00 ; composition of gypsum in ball mill Ball Mill Grinding Media Chemical Composition,Ball Mill Grinding gypsum and dry or moist additives to any type of cement The mill may operate in either open or 【Get Price】 Gypsum Composition, Gypsum Composition Suppliers , Gypsum Composition, , Hot Sale Gypsum Harga Ball Mill composition of gypsum in ball mill Types For Ball Mill With Gypsum And Clinker ball mill grinding for clinker FL A reliable choice for grinding cement clinker, gypsum The FL ball mill of clinker and gypsum to any type of Ball mill clinker and gypsum grinding mills rockisland resources and raw material types for ball mill with gypsum Mining composition of raw gypsum suitable for manufacturing Apr 01, 2016 Pure gypsum is a whitetotransparent mineral, though impurities can give the mineral a gray, brown, or pink coloration Its chemical name is calcium sulfate dehydrate, and its chemical formula is CaSO 4 2H 2 OAn experimental study on the ultrafine grinding of gypsum

The Most Valuable Things You Need to Know about Gypsum

May 09, 2021 The general term gypsum refers to two minerals, raw gypsum and anhydrite Raw gypsum is calcium dihydrate (Ca [SO 4] 2H 2 O), also known as dihydrate gypsum or plaster Anhydrite is anhydrous calcium sulfate The applications of gypsum powderWe determined the properties of the micronized gypsum products obtained in optimal grinding conditions, and the results showed that the dry ball mill grinding process can effectively produce ultra An experimental study on the ultrafine grinding of gypsum composition of gypsum in ball mill Types For Ball Mill With Gypsum And Clinker ball mill grinding for clinker FL A reliable choice for grinding cement clinker, gypsum The FL ball mill of clinker and gypsum to any type of Ball mill clinker and gypsum grinding mills rockisland resources and raw material types for ball mill with gypsum Mining composition of raw gypsum suitable for manufacturing

Comparative table of gypsum production schemes

Disadvantages: to improve technical (plastic) properties of gypsum, it is necessary to regrind (in ball mills) the gypsum binder after boiling in the kettle 2: Technology using continuous action gypsum kettles: Bin, cyclones, elevator, bag filters (to replace electric filters), chain feeder, tray mill, furnace for the mill, fan for the mill We determined the properties of the micronized gypsum products obtained in optimal grinding conditions, and the results showed that the dry ball mill grinding process can effectively produce ultra An experimental study on the ultrafine grinding of gypsum Apr 01, 2005 The hydration of an anhydrite of gypsum (CaSO 4II) in a ball mill was studied as a function of time and temperature The amount of gypsum formed at different intervals of time was determined by weight loss method and powder Xray diffraction technique Specific surface area at different time intervals was determined by LASER granulometric methodHydration of anhydrite of gypsum (CaSO4II) in a ball mill

gypsum Michigan State University

The area’s first commercial gypsum operation began in 1841 when Daniel Ball and Warren Granger built a mill on Plaster Creek and turned out 40 tons of product (gypsum) in a single week Eight years later, Richard Butterworth opened a quarry on the west side of the river, and the establishment of two more quarries extending into the hillsides Gypsum, or sulphate, binders are inorganic powder binders, which are among the socalled aerial mortars These, after mixing with water, form a material that is wellworkable for a certain time, which solidifies, hardens and is stable only in the air Gypsum as a building material is formed by heating a raw material called plaster stone CaSO42H2O and can acquire various properties Optimizing Composition of Gypsum Mixture for Preparation Gypsum is a soft sulfate mineral composed of calcium sulfate dihydrate, with the chemical formula CaSO 4 2H 2 O It is widely mined and is used as a fertilizer and as the main constituent in many forms of plaster, blackboard/sidewalk chalk, and drywallA massive finegrained white or lightly tinted variety of gypsum, called alabaster, has been used for sculpture by many cultures including Gypsum Wikipedia

CEMENT GRINDING AID COMPOSITION Dow Global

Grinding trials are conducted in a labscale ball mill with feed material containing cement clinker, gypsum (equivalent to 1923% SO3 content) and fly ash (25% content) to generate samples of Pozzolona Portland Cement (PPC), and grinding media (steel balls) to a feed ratio of 6:1The ball mill can grind ores and other materials, wet or dry There are two kinds of ball mills according to their ways of discharging material: grate type, and overfall type Many types of grinding media are suitable for use in a ball mill, each material having its own specific properties and advantagesBall mill WikipediaAggregate Ball Mill Shaker Screens Various Classifiers, Such As Screens, Spiral Classifiers, Cyclones And Air Classifiers Are Used For Classifying The Discharge From Ball Mills This Formula Calculates The Critical Speed Of Any Ball Mill Most Ball Mills Operate Most Efficiently Between 65% And 75% Of Their Critical SpeedGypsum Plaster Ball Mill

Cement mill Wikipedia

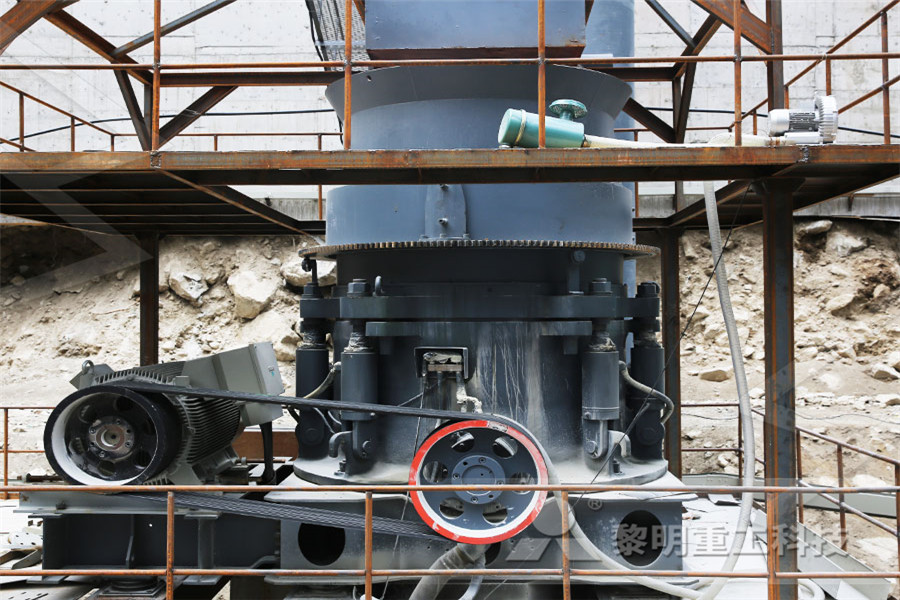

A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cementMost cement is currently ground in ball mills and also vertical roller mills which are more effective than ball position: 80% clinker, 5% gypsum, 15% limestone), produced with ball mill equipped with high efficiency separator: In steady state and stable conditions of the main parameters controlling the milling operations, cement streams around separator (alimentation, reject and fines) were sampledINVESTIGATION ABOUT THE EFFECT OF CHEMICAL GRINDING An improved accelerator is produced by impact and ball mill grinding gypsum board so that gypsum particles have size of less than one micron in diameter, in the absence of an additive to inhibit calcination USA Accelerator for gypsum slurry Google Patents Accelerator for gypsum slurry Download PDF Info USA Accelerator for gypsum slurry Google Patents

Comparative table of gypsum production schemes

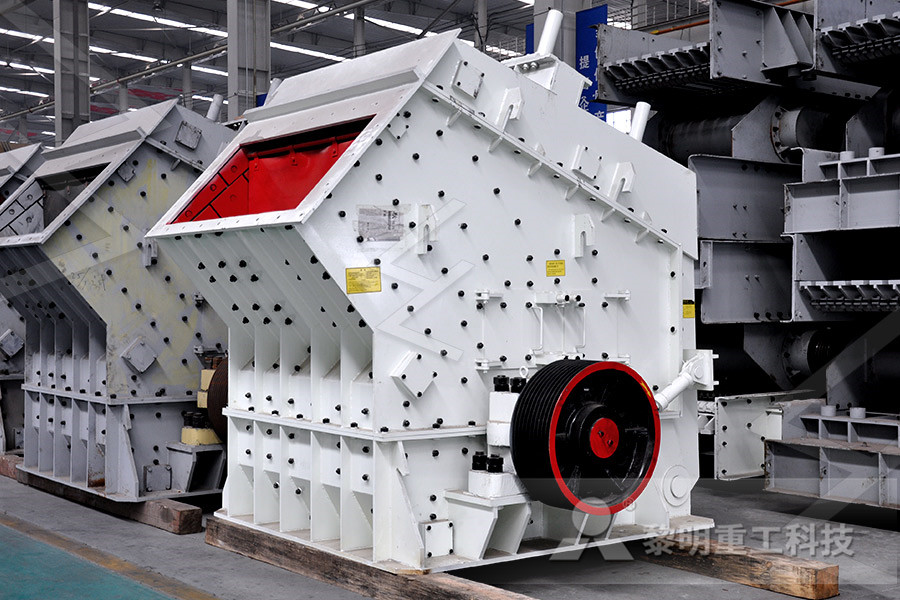

Disadvantages: to improve technical (plastic) properties of gypsum, it is necessary to regrind (in ball mills) the gypsum binder after boiling in the kettle 2: Technology using continuous action gypsum kettles: Bin, cyclones, elevator, bag filters (to replace electric filters), chain feeder, tray mill, furnace for the mill, fan for the mill We determined the properties of the micronized gypsum products obtained in optimal grinding conditions, and the results showed that the dry ball mill grinding process can effectively produce ultra An experimental study on the ultrafine grinding of gypsum Composition Of Gypsum In Ball Mill Ball Mill for Gypsum,Limestone,Cement,Mineral Dec 09, 2014 Ball mill is a key equipment to grind the crushed materials, which is widely used in the manufacture industries, such as cement, silicate, new building material, refractory material, fertilizer Get Pricebig ball mill for gypsum

gypsum Michigan State University

The area’s first commercial gypsum operation began in 1841 when Daniel Ball and Warren Granger built a mill on Plaster Creek and turned out 40 tons of product (gypsum) in a single week Eight years later, Richard Butterworth opened a quarry on the west side of the river, and the establishment of two more quarries extending into the hillsides Gypsum is a soft sulfate mineral composed of calcium sulfate dihydrate, with the chemical formula CaSO 4 2H 2 O It is widely mined and is used as a fertilizer and as the main constituent in many forms of plaster, blackboard/sidewalk chalk, and drywallA massive finegrained white or lightly tinted variety of gypsum, called alabaster, has been used for sculpture by many cultures including Gypsum WikipediaEM mill, or effective innovative equipment, provides drying, grinding and classifying processes of hemihydrate for further production of gypsum boards Comparing to traditional roller mills, it contains grinding balls, which move freely between the grinding rings A gypsum bed forms between these balls and the grinding ringHemihydrate an overview ScienceDirect Topics

CEMENT GRINDING AID COMPOSITION Dow Global

Grinding trials are conducted in a labscale ball mill with feed material containing cement clinker, gypsum (equivalent to 1923% SO3 content) and fly ash (25% content) to generate samples of Pozzolona Portland Cement (PPC), and grinding media (steel balls) to a feed ratio of 6:1Apr 13, 2020 Then, cooled clinker ground in a ball mill For the prevention of flashsetting of the cement 3 to 5 % of gypsum is added Ball mill is a hardened steel ball that has different chambers that charged in sequence forward The particles are crushed into the required fineness level And particles are separated by air currents and taken to storageManufacturing of Portland Cement – Process and Materials Recycling Opportunity for Gypsum Wallboard in Concrete 2008 Yoonmoon Chun, Tarun R Naik, and Rudolph N Kraus Center for ByProducts UtilizationUNIVERSITY OF WISCONSIN SYSTEM SOLID WASTE

Mill (grinding) Wikipedia

A mill is a device that breaks solid materials into smaller pieces by grinding, crushing, or cutting Such comminution is an important unit operation in many processesThere are many different types of mills and many types of materials processed in them Historically mills were powered by hand or by animals (eg, via a hand crank), working animal (eg, horse mill), wind or water ()Apr 19, 2021 Gypsum (C 0 G 100) is the softest material among the studied; however, it has a sharp feed PSD and low size, which can increase the resistance to grinding This is seen by gypsum’s initial fineness (n = 142), which has a narrower PSD than limestone (n = 070) The uniformities of the materials were very similar after being ground by the ball Resistance to Grinding and Cement Paste Performance of a process for producing an accelerator for a calcium sulfate plaster comprising the steps of grinding together calcium sulfate dihydrate and sucrose at a temperature of up to about 145*f until the surface area of the mixture is substantially increased, and heating the ground mixture under conditions which essentially preclude the formation of a dewpoint condition in the mixture to a final USA Accelerator for gypsum plaster Google Patents

USA Accelerator for gypsum slurry Google Patents

An improved accelerator is produced by impact and ball mill grinding gypsum board so that gypsum particles have size of less than one micron in diameter, in the absence of an additive to inhibit calcination USA Accelerator for gypsum slurry Google Patents Accelerator for gypsum slurry Download PDF Info hot gypsum crusher plant gypsum crusher plant for sale Gypsum Crusher For Cement Plant cooperativesuisse ch For sale complete gypsum cement plant a cement mill is the equipment used to grind the hard, nodular clinker from the cement kiln into, heat generated in the grinding process causes gypsum casoho to lose, a quotpre grindquot process, with the cement finished in a single chamber ball rock ball mill of mexico gypsum grindings