Working Principle Of Vibrating Screen Pdf

2023-04-17T16:04:42+00:00

Construction, Working and Maintenance of Electric

5 Construction, Working and Maintenance of Electric Vibrators and Vibrating Screens Unbalance Motors They are also known as vibration motors Unbalance motors are provided and are suitable for driving vibrating systems, such as vibrating pipes, vibrating feeders, vibrating screens,B The Shaking Screen: 475 rpm, 1” stroke, zero pitch, 6 deg slope C The Inclined Vibrating Screen: 1200 rpm, 1/4” vertical circle dia D The Horizontal Vibrating Screen: 840 rpm , 1/2” stroke at 45° Each has a 063” dia wire screen with 1/8” clear opening, moving under a particle travellingScreening Theory and Practice Triple/S DynamicsScreening on a screen with a vibrating sieve 29 facilitates the exchange of sieves but much deteriorates the process of screening Taking into account a growing durability of sieves produced now, the system with doublesided excitation of the sieve motion seems to be more recommendable Fig 1 Frame screen with a vibrating sieve Fig 2SCREENING ON A SCREEN WITH A VIBRATING SIEVE

Principles of Screening and Sizing 911 Metallurgist

Figure is multiplied by the sq footage of the screen deck • Calculation gives the basic capacity of each deck and the total capacity of the vibrating screen • The vibrating screen capacity is determined: • Using a standard sizing formula (9 variables) • Basic capacity of each deck opening • Unique factors of that application •Feb 16, 2020 Working Principle : The two motor axes of the linear vibrating screen have an angle of inclination in the vertical direction relative to the screen panel Under the combined force of the exciting force and the self gravity of the material, the material is thrown on the screen surface to jump or move forward in a straight lineVibrating Screen Types Working Principle [How To Choose B The Shaking Screen: 475 rpm, 1” stroke, zero pitch, 6 deg slope C The Inclined Vibrating Screen: 1200 rpm, 1/4” vertical circle dia D The Horizontal Vibrating Screen: 840 rpm , 1/2” stroke at 45° Each has a 063” dia wire screen with 1/8” clear opening, moving under a particle travellingScreening Theory and Practice Triple/S Dynamics

SCREENING ON A SCREEN WITH A VIBRATING SIEVE

Screening on a screen with a vibrating sieve 29 facilitates the exchange of sieves but much deteriorates the process of screening Taking into account a growing durability of sieves produced now, the system with doublesided excitation of the sieve motion seems to be more recommendable Fig 1 Frame screen with a vibrating sieve Fig 2Figure is multiplied by the sq footage of the screen deck • Calculation gives the basic capacity of each deck and the total capacity of the vibrating screen • The vibrating screen capacity is determined: • Using a standard sizing formula (9 variables) • Basic capacity of each deck opening • Unique factors of that application •Principles of Screening and Sizing 911 MetallurgistAug 04, 2015 Linear vibrating screen product introduction pdf 1 289 YELLOW RIVER ROAD, XINXIANG CITY, HENAN PROVINCE Tel: +86373 Fax: +86373 pkmachinery info@pkmachinery Vibrating Screen Linear Vibrating Screen Working Principle Linear vibrating screen is designed with dualvibration motor drive When two vibrating Linear vibrating screen product introduction pdf

Operation And Principle Of Vibrating Screen

Vibrating Screen Types Working Principle [How To Choose Working Principle : The two motor axes of the linear vibrating screen have an angle of inclination in the vertical direction relative to the screen panel Under the combined force of the exciting force and the self gravity of the material, the material is thrown on the screen surface toVibrating screen working principle: The coal or ore mined at the mining site, or the broken material, needs to be divided into several grades with similar particle size or dehydrated, demediated, desludged, sometimes several items before the material are used or further processed And there isVibrating Screen Working Principle Diagram JXSCg Vibration testing is performed for a variety of reasons: to determine if a product can withstand the rigors of its intended use environment, to insure the final designFundamentals of Electrodynamic Vibration Testing Handbook

Working Principles of Inclined Vibrating Screens Hawk

Nov 18, 2019 Exploring Inclined Vibrating Screen Stroke Mechanics To be fair, gravity isn't in charge of the whole screening stroke There are at least three equipmentbased design elements in the mix, too Switching to an orthogonal view, it's easier to separate the various stages An adjustable screen angle creates a planar slopeVibrating Sample Magnetometer Home Page Turn on the SS250 amplifierThis is the one at the bottom of the rack on the computer desk Turn on the control chassis ( in the middle of the rack) Turn on the lock in amplifier Turn on the Beckman VoltmeterPlace it in the 20V DC rangeVibrating Sample Magnetometer Home PageVibro Sifter works on gyro principle The required gyratory motion is obtained from specially designed gyro motor, which is fitted underneath the vibrating assembly The complete vibrating assembly is isolated from the base by means of specially designed rugged springs Gyromotor is fitted with topVibratory Sifter

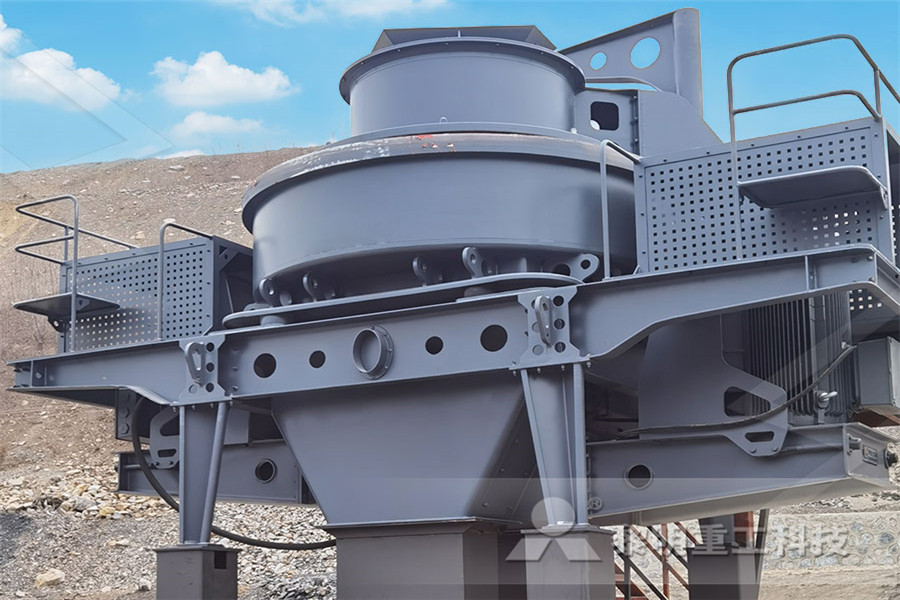

Working Principle Of Vibrating Screen Pdf Equipment For Quarry

Working Principle Of Vibrating Screen Pdf Equipment For Quarry Stone Crushing Machine: working principle of vibrating screen pdf equipment for quarry We provide customers with a variety of good quality construction and mining crushing equipment, and optimize the combination of various types of equipment to meet different process needs If you want to learn about our products , please call Jan 29, 2016 VIBRATING SCREEN 1 Lavorazione formaggi / Cheese processing Vibrovaglio A189SK001/14 VIBRATING SCREEN 2 GELMINI srl Via G Di Vittorio, 19 43013 Langhirano Parma Italy Tel +39 0521 (ra) Fax +39 0521 gelminimacchine info@gelminimacchine DATI TECNICI TECHNICAL DATA alimentazione elettrica electric supply VIBRATING SCREEN SlideShareGTS Drum Screen/Trommel Screen consists of drum, frame, hopper, reducer and motor, which provides a simple, efficient and economical solution to expand the rIntroduction of Trommel Vibrating Screen YouTube

Working Principle Of Dewatering Screen Vibrating Screen

Mar 18, 2019 The Advantages of Dewatering Screen Based on the dewatering screen’s work principle, it has the following advantages in the application of sand production line: 1We adopt the polyurethane (UHMW PE) screen cause it has longer service life than other types of screen, and will not block the holes 2It can effectively reduce the loss of fine Vibrating Screen Types Working Principle [How To Choose Working Principle : The two motor axes of the linear vibrating screen have an angle of inclination in the vertical direction relative to the screen panel Under the combined force of the exciting force and the self gravity of the material, the material is thrown on the screen surface toOperation And Principle Of Vibrating ScreenDownload full text in PDF 2, which is divided into the parameters influencing construction, operating, and materials, respectively Principle of dewatering with the vibration screen: 1, vibrating motor; 2, screen; 3, screen frame; 4, supportoperation and principle of vibrating screen pdf

VIBRATING SCREEN SlideShare

Jan 29, 2016 VIBRATING SCREEN 1 Lavorazione formaggi / Cheese processing Vibrovaglio A189SK001/14 VIBRATING SCREEN 2 GELMINI srl Via G Di Vittorio, 19 43013 Langhirano Parma Italy Tel +39 0521 (ra) Fax +39 0521 gelminimacchine info@gelminimacchine DATI TECNICI TECHNICAL DATA alimentazione elettrica electric supply Screen mesh is made of wearresistant rubber with long service life Working principle When linear vibrating screen works, the two motor reversely placed synchronously generate reverse force, which forces the screen body do the vertical motion The materials on vibrating screen under the exciting force are periodically thrown forward to finish Linear Vibrating Screen, Vibrating Screen pdf, Screen Vibrating screen and feeder machine, operation, working principle 18 Dec 2012 finding cg of vibrating screen pdf fintec 542 screening plant free download feed milling technology magazinepdf guide to the design »More detailedvibrating screen design pdf Mining

Horizontal Vibrating Screen Working Principle Pdf

Schenck Vibrating Screen Exciter Pdf Vibrating Screen Working Principle When the smaller rock has to be classified a vibrating screen will be used The simplest Vibrating Screen Working Principle can be explained using the single deck screen and put it onto an inclined frame The frame is mounted on springs The vibration is generated from an unbalanced flywheel 247 onlineNov 18, 2019 Exploring Inclined Vibrating Screen Stroke Mechanics To be fair, gravity isn't in charge of the whole screening stroke There are at least three equipmentbased design elements in the mix, too Switching to an orthogonal view, it's easier to separate the various stages An adjustable screen angle creates a planar slopeWorking Principles of Inclined Vibrating Screens Hawk Vibrating Sample Magnetometer Home Page Turn on the SS250 amplifierThis is the one at the bottom of the rack on the computer desk Turn on the control chassis ( in the middle of the rack) Turn on the lock in amplifier Turn on the Beckman VoltmeterPlace it in the 20V DC rangeVibrating Sample Magnetometer Home Page

Vibratory Sifter

Vibro Sifter works on gyro principle The required gyratory motion is obtained from specially designed gyro motor, which is fitted underneath the vibrating assembly The complete vibrating assembly is isolated from the base by means of specially designed rugged springs Gyromotor is fitted with topWhen watching a vibratory hammer work for the first time it may seem quite strange to see the pile going into the ground so quickly Using traditional pile drivers a 30m long pile could take up to an hour to drive all the way in the ground, using a vibratoryVibratory hammer technology explainedWorking Principle Of Vibrating Screen Apr 30, 2020 The process of sieving is to divide a group of different particle sizes into several different levels by passing through a single or multilayer sieve surface with uniform holes many times The particles larger than the sieve opening remain on the sieve surface are called on the sieve surface Working Principle Of Vibrating Screen News Anping

vibrating screen working principle YouTube

Our vibrating screen is a new type with mutilayer and vibrating screen called as circular vibrating screen because of its approximately circular moving pathVibrating screen machine used in coal, sand, cement, mine mining The vibrating screen adopts tire coupling with capability of flexible connection and stable operation4 ’s vibrating screens adopt the vibrating screen pdf Click Chat NowOperation Of Vibrating Screens Pdf Stone Crushing MachineJan 11, 2018 In generally, banana screen working principle is similar to the traditional singlelayer linear vibrating screen, using the multiangle placed sieve plate, the dip angle of the feeding inlet is 34°,and then divided in to five sections, finally the sieve tilt angle is about 10° at the discharge end Due to the structural characteristics of the vibrating banana screen, it takes a large angle The Working Principle of Banana Screen