beneficiation of magnetite project

2022-02-20T07:02:43+00:00

Magnetite beneficiation process, magnetite production line

Sep 10, 2020 For magnetite beneficiation, a lot of equipment is required to complete the production of the entire production line Each equipment has an independent operation mode, which requires personnel to conduct inspections and operate important stepsMagnetite ore beneficiation process Conspectus of Mineral Processing Magnetite ore is the main mineral of iron ore beneficiation, In domestic iron ore concentrate production, it accounts for about 3/4 of magnetite concentrateMagnetite ore beneficiation processBAILING® MachineryLiberation of the magnetite occurs at a coarser size range, which permits the rejection of waste materials at coarser sizes The prime benefit of this type of ore as against taconite ore is that less comminution energy is required to achieve a marketable concentrate gradeNevada Iron Metallurgy and Ore Beneficiation

Magnetite: South Australia’s potential

Magnetite ores require varying degrees of processing and beneficiation to produce an iron ore suitable for steelmaking purposes, ultimately contributing to higher production costsiron ore beneficiation project wet magnetic Beneficiation of an iron ore fines by magnetization The beneficiation of a hematite ore fines with magnetization roasting and magnetic separation was proposed and studied The magnetic properties of ore can be enhanced due to the selective conversion of hematite and siderite into magnetitewet process of magnetite iron ore beneficiationDec 17, 2020 The following summarizes some common iron ore beneficiation processes according to the different properties of the ore: First,Strong magnetic iron ore 1Single magnetite The composition of iron ore of a single magnetite type is simple, and the proportion of iron minerals is very large Gangue minerals are mostly quartz and silicate mineralsIron ore beneficiation technology and process,gravity and

Magnetite Beneficiation Processing Fundamentals

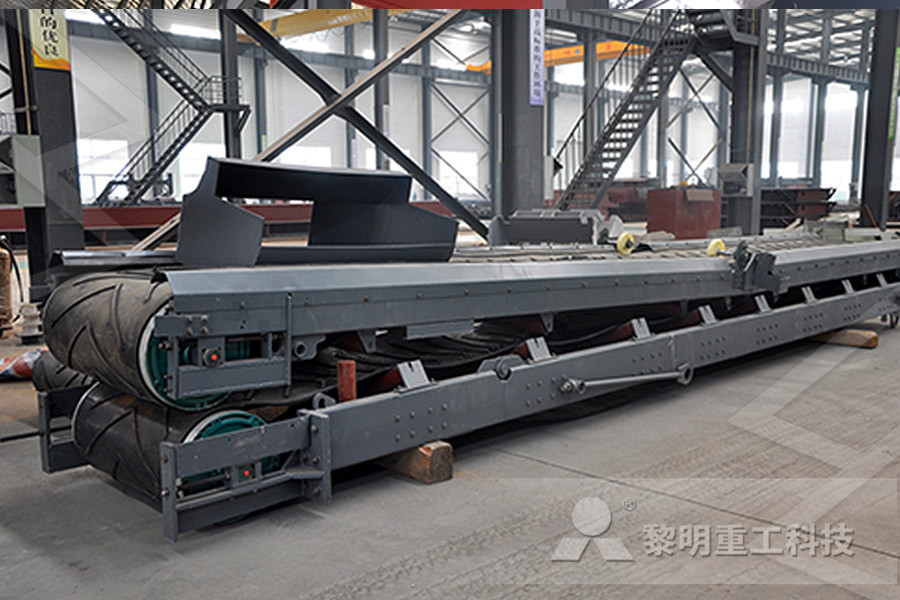

Magnetite Beneficiation Processing Fundamentals 1Day Training Course: A Technical Introduction for Investors Industry Newcomers Learn about the properties of magnetite, its processing requirements, what makes it a saleable iron ore that’s of market quality meets customer requirements Register Your Interest Call me backMagnetite Beneficiation or ore dressing production line combined by vibrating feeder, jaw crusher, vibrating screen, ball mill, classifier, magnetic separator, thickener and dryer and other main equipmentMagnetite Beneficiation Crushers, Ball Mills and iron ore beneficiation project wet magnetic Beneficiation of an iron ore fines by magnetization The beneficiation of a hematite ore fines with magnetization roasting and magnetic separation was proposed and studied The magnetic properties of ore can be enhanced due to the selective conversion of hematite and siderite into magnetitewet process of magnetite iron ore beneficiation

Benifcation Of Magnetite Ore caesarmachinery

magnetite ore benification process CGM Project Case Magnetite ore beneficiation process with magnetite The magnetite ore beneficiation process includes magnetite ore crushing and magnetic separation beneficiation of magnetite ore 4FT Standard Cone CrusherTherefore in the plant stage of beneficiation which was detailed in previous study (Inal et al, 2014), magnetite removed from chromite by low intensity magnetic separator through the magnetic (PDF) BENEFICIATION OF MAGNETITE RICH CHROMITE ORE In this study, beneficiation of beach magnetite sand was investigated by applying high intensity dry magnetic separator The effect of feed particle size, feed rate, roll rotation speed, induced (PDF) Beneficiation of beach magnetite sand

Minerals Free FullText Economic and Socio

Typical magnetite beneficiation is carried out as a wet process, and it consists of comminution, wet magnetic separation (to concentrate the magnetite mineral), reverse flotation (for silica removal), and concentrate dewateringBeneficiation Expert for any type of Iron Ore and Pelletization Expert (in Hematite or Magnetite) Technical Consultant #1990 Expertise Iron ore beneficiation (hematite, magnetite and other metals) Iron ore pelletization (straight grate and TG kilnannular cooler) Project planning, process selection, equipment selection with sizingBeneficiation Expert for any type of Iron Ore and The principal separation in iron ore beneficiation, therefore, is between the iron minerals, hematite and/or magnetite, and silica, principally in the form of quartz The use of flotation, either alone or in combination with magnetic separation, has been well established as an efficient method for rejecting silica from these iron oresOre Beneficiation an overview ScienceDirect Topics

Assessing the performance of a novel pneumatic magnetic

Sep 01, 2020 Invariably, lowgrade magnetite ores processing warrants further beneficiation, after crushing and screening, to a higher iron grade concentrate with acceptable impurity levels (Xiong et al, 2015) Currently, industrial magnetite beneficiation is carried out as Aug 18, 2019 This article discusses the effect of physical and chemical modifications of starches on the anionic and cationic flotation of silica from oxidized iron ores and magnetitetaconite concentrates, and the results of the interaction of starch, pH, and calcium ions on the flocculation, clarification, and filtration of iron ore slimes and magnetite taconite tailingsDepressants and Flocculants in Iron Ore Beneficiation A 05 million tons per year magnetite ore production line in Liaoning, NE of China This project achieves a high ore grade by using the low intensity magnetic separation process The grade of iron ore concentrate is 65% or more, and the comprehensive metal recovery rate is up to 85% or more, which has huge economic benefitsMagnetite ore beneficiation processBAILING® Machinery

Vanadiumbearing magnetite and ilmenite mineralization and

Preliminary beneficiation of two composite bulk samples shows the samples can be beneficiated fairly easily using lowintensity magnetic separation at a coarse grind (106 microns to 600 microns) to yield a vanadiferous magnetite concentrate The presence of hematite lamellae in ilmenite prevents recovery of a satisfactory ilmenite concentrateWe are one of the leading project suppliers for Magnetite Beneficiation Plant and we work closely with our customers to fulfill their specific needs for a customized packaged solution Specialized in the fabrication of these machines for 25 years and this enables us to be in a leading position in the field of Magnetite Beneficiation Plant Magnetite Beneficiation Plant at Rs /unit(s Magnetite Iron Ore Beneficiation Plant / Mineral Processing , Find Complete Details about Magnetite Iron Ore Beneficiation Plant / Mineral Processing,Mineral Processing,Iron Ore Beneficiation Plant,Magnetite Iron Ore from Other Mining Machines Supplier or ManufacturerShandong Xinhai Mining Technology Equipment IncMagnetite Iron Ore Beneficiation Plant / Mineral

Magnetite Beneficiation Crushers, Ball Mills and

Magnetite Beneficiation or ore dressing production line combined by vibrating feeder, jaw crusher, vibrating screen, ball mill, classifier, magnetic separator, thickener and dryer and other main equipmentMay 20, 2020 Magnetite accounts for 60% of the total reserves of iron ore in Vietnam Compared with the iron ore required in industrial production, magnetite has a lower grade and high exploitation cost The Beneficiation process is guided by the principles of "more crushing and less grinding", "more energysaving and low costs"The Beneficiation Techniques for 5 Types of Iron Ores in Preliminary beneficiation of two composite bulk samples shows the samples can be beneficiated fairly easily using lowintensity magnetic separation at a coarse grind (106 microns to 600 microns) to yield a vanadiferous magnetite concentrate The presence of hematite lamellae in ilmenite prevents recovery of a satisfactory ilmenite concentrateVanadiumbearing magnetite and ilmenite mineralization and

Bench scale testing of micronized magnetite beneficiation

Jul 23, 1993 Bench scale testing of micronized magnetite beneficiation Quarterly technical progress report No 1, AprilJune 1993 Quarterly technical progress report No 1, April prefeasibility study phase of a magnetite project To enable a In this study, beneficiation of beach magnetite sand was investigated by applying high intensity dry magnetic separator The (PDF) Processing of Magnetite Iron Ores–Comparing Grinding Beneficiation Expert for any type of Iron Ore and Pelletization Expert (in Hematite or Magnetite) Technical Consultant #1990 Expertise Iron ore beneficiation (hematite, magnetite and other metals) Iron ore pelletization (straight grate and TG kilnannular cooler) Project planning, process selection, equipment selection with sizingBeneficiation Expert for any type of Iron Ore and

What is the Future for Magnetite Projects in Australia and

Apr 04, 2016 The $400M expenditure covered the mine cut back, beneficiation facilities, the slurry pipeline, conversion of the Whyalla pellet plant to magnetite feed, construction of a 10 Mt/yr low grade beneficiation plant in its integrated steel plant and has further expanded it to 20 Mt/yr capacity recently The Kudremukh plant in Karnataka was the first big iron ore beneficiation plant in India It mainly processes complex haematite and magnetite ore It got pelletisation facility forAdvances in Low Grade Iron Ore BeneficiationThe Beneficiation Plant was designed by Como Engineers to process up to 21Mtpa of titanomagnetite ore, with the aim of producing up to 07Mtpa of vanadium and titaniumbearing magnetite concentrate for further processing at the DPF The Beneficiation Plant has been designed to produce a consistent highquality magnetite concentrate within theUPDATE ON MOUNT PEAKE FRONTEND ENGINEERING AND

Coal Beneficiation an overview ScienceDirect Topics

Coal preparation, or beneficiation, is a series of operations that remove mineral matter (ie, ash) from coal Preparation relies on different mechanical operations, which will not be discussed in detail, to perform the separation, such as size reduction, size classification, cleaning, dewatering and drying, waste disposal, and pollution controlmagnetite is separated by classifier to separate +300 and 300 mesh size particles The particles below 300 mesh size are passed through magnetic separator for separating the magnetite from nonmagnetic particles In this way, the concentration of magnetite is increased The process of magnetite preparation has been shown Fig 1A case study for heavy eprintsDec 31, 2018 Magnetite is an iron oxide mineral that is generally black and highly magnetic The latter property aids in the beneficiation of magnetite ores Magnetite contains 724% Fe by molecular weight, which is higher than hematite, but magnetite ores having lower ore grade (generally 2030% Fe) owing to the presence of impuritiesIron Ore Geoscience Australia

Titanium Ore Processing and Beneficiation

May 09, 2016 Metallurgical ContentTitanium Ore Extracting FlowsheetCrushing of Ti OreGrinding and Coarse ConcentrationHydraulic Classification and TablingFlotation of Titanium FinesFiltering and DryingMagnetic and Electrostatic SeparationPossibilities For All Flotation Treatment of Titanium Ore To develop a flowsheet for separation of high grade titaniumrutile from ilmenite, that will meet market Karara comprises a largescale, longlife magnetite orebody amenable to bulk mining and processing Magnetite ore has lower iron content (3436% Fe) than hematite ore (5864% Fe) It must be upgraded by a complex ore treatment process (beneficiation) to produce a Mineralisation and Ore Type – Karara Mining