in in pit crushing in australia

2022-06-01T07:06:00+00:00

In Pit Crushing In Australia

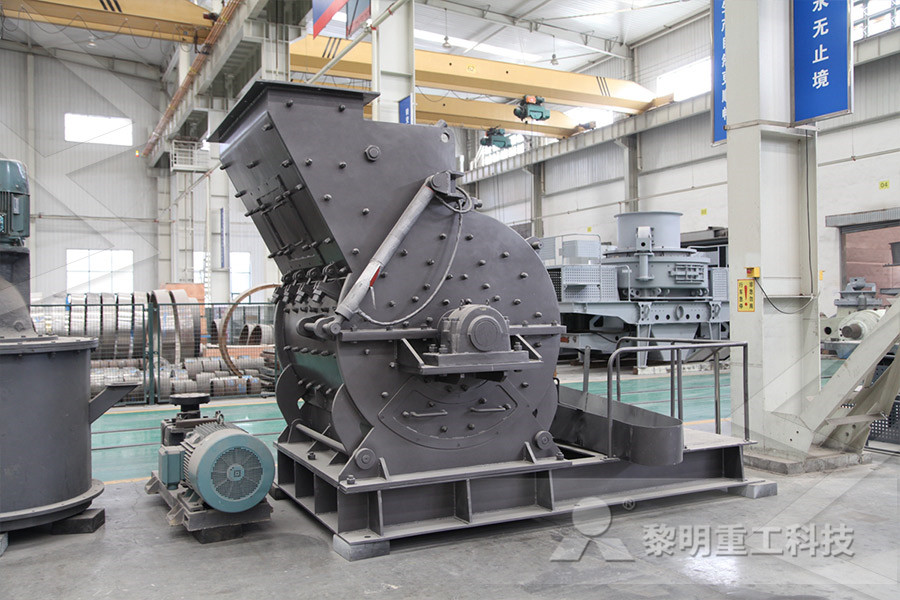

In Pit Crushing In Australia We are a professional mining machinery manufacturer, the main equipment including: jaw crusher, cone crusher and other sandstone equipment;Ball mill, flotation machine, concentrator and other beneficiation equipment; Powder Grinding Plant, rotary dryer, briquette machine, mining, metallurgy and other related equipmentIf you are interested in our products or want Feb 06, 2013 In pit crushing and conveying is being touted as the future of open cut mining Can the greater use of inpit crushing and conveying (IPCC) systems by Australian mining companies reduce their exposure to the skills shortage, equipment and tyre availability problems, diesel fuel requirements and help companies with their carbon credits?In Pit Crushing and Conveying: Changing the face of the Client: Rio Tinto Coal Australia Rio Tinto Clermont Mine in Central Queensland uses an InPit Crushing and Conveying System (IPCC) for a major component of its overburden stripping for the mineIn Pit Crushing and Conveying (IPCC) Systems

Inpit crushing with Lokotrack LT160 the largest mobile

Apr 15, 2014 Inpit crushing with Lokotrack LT160 the largest mobile crusher in the Southern Hemisphere The Australian quarry industry’s demands for greater efficiencies as well as higher standards of safety and sustainability encouraged Boral to choose 's Lokotrack LT160Inpit crushing and conveying (IPCC) is an alternative transport system which requires a higher initial investment but gives substantial saving in operating cost IPCC is the superior technology(PDF) Review of the inpit crushing and conveying (IPCC Mar 15, 2021 After the initial crushing by the inpit crushers, the bricksized rock is transported via conveyor to the Processing Plant, where it’s put through a series of crushers and mills First the ore goes into autogenous grinding mills and then ball mills, where the crushing process continues until it’s a Our Operation Citic Pacific Mining

InPit Crushing

Interest in inpit crushing and conveying (IPCC) technologies continues to grow and, with some flagship projects nearing completion, now seems a good time to review activity in the sector “The last year was good for new orders,” Thomas Jabs, senior vice president for mining at , told EMJInpit crushing and conveying system underwent two years of testing at iron ore mine Comminution 02 OCTOBER 2015 IPCC So where's the grade control? The addition of in pit crushing and separation techniques is helping to take IPCC to the next level Comminution 01 APRIL 2015Mining Magazine In Pit Crushing And Conveying Page 1The existing inpit crushing system will be retained at least until the present concentrator is shut down and during this period a new semimobile inpit crushing plant will be installed in the northern section of the openpit, as well as a new crusher on the surface close to a stockpile feeding the 35km overland conveyor to the new concentratorNew Focus on InPit Crushing Systems

In Pit Crushing and Conveying (IPCC) Systems

Client: Rio Tinto Coal Australia Rio Tinto Clermont Mine in Central Queensland uses an InPit Crushing and Conveying System (IPCC) for a major component of its overburden stripping for the mine The IPCC consists of a fully mobile sizing rig operating in the upper levels of the pit combined with, a ramp conveyor, 25km movable pivoting dump Introduced in 1993–94 by the then for quarrying, the inpit crushing and conveying (IPCC) concept with a mobile crusher following an excavator along the face and discharging to a linked conveyor system has been scaled up for mining applications since 2000 Australia and subsequently supplied Suncor’s first fully mobile unit for Sandvik Sharpens InPit Crushing Focus E MJInPitCrushing and Conveying (IPCC) Operational costs, work safety and CO 2 emissions are challenges faced by most mines today While there certainly isn't a «onesizefitsall» solution to solve these issues, InPit Crushing and Conveying (IPCC) systems cut truck haulage to a minimum and build operational resilienceInPitCrushing and Conveying (IPCC)

Sino Iron Project, Cape Preston, Western Australia

The four inpit crushers from Germany have a crushing capacity of crushing 4,250t of ore an hour a unit The conveyer belt bearing crushed ore from the mine to the concentrate area is approximately 17km The main AG mill with 28MW gearless motors has a diameter of 122m and a length of 11mSep 15, 2011 Once in place and commissioned, each of the four inpit crushers will have the capacity to crush 4,250 t/h of magnetite, making it the largest inpit crushing system in Australia During operations, the crushers will be fed by 363 t Unit Rig MT6300 AC trucks, originally delivered by Mining but now part of First massive ThyssenKrupp inpit crusher successfully PH Inpit CrushingConveying Systems are the newest addition to the PH Mining Equipment product line Introduced in 2008, IPCCs take earthen material excavated and deposited into a large holding hopper by a PH electric shovel, and then crush the material to an easytoconvey size for transfer elsewhere in the minePH Mining Wikipedia

PH Komatsu Mining Corp

Later, an inpit crushing and conveying system was introduced – featuring a mobile mining crusher that matches the shovel’s capacity and robust crushingconveying technology – representing an exciting new material handling strategy option for minesThe existing inpit crushing system will be retained at least until the present concentrator is shut down and during this period a new semimobile inpit crushing plant will be installed in the northern section of the openpit, as well as a new crusher on the surface close to a stockpile feeding the 35km overland conveyor to the new concentratorNew Focus on InPit Crushing SystemsOct 31, 2013 Introduction In Pit Crushing Conveying (IPCC)In Pit Crushing Conveying (IPCC) 1 Continuous mining is common in lignite soft coal mines for decades – loading using bucket wheel excavators, continuous haulage by conveyors, waste dump spreaders 22 In hard rock applications – truck and shovel is prevalent 331102013 Sandvik In Pit Crushing Conveying (IPCC

in pit crushing and conveying gathering momentum

in pit crushing conveying belgianshepherdcoza In pit crushing and conveying saves more than just For waste crushing takes place only to make the material transportable on the conveyor for ore in pit crushing is a part of the total comminution process Crushing waste rock in the pit has several benefits If the waste rock has to be crushed crushing it in the pit and conveying itInterest in inpit crushing and conveying (IPCC) technologies continues to grow and, with some flagship projects nearing completion, now seems a good time to review activity in the sector “The last year was good for new orders,” Thomas Jabs, senior vice president for mining at , told EMJInPit CrushingCoal Australia Crusher Coal crusher for sale australia laboratory australia coal crushing lab3d coal crusher sale in australia feb 9, 2017 mining industrybest solution of roller crusher for sale in coal the required capacity is 35 ton per hour in australia coal crushing plant, what is grays mining specialising in the valuation and sale ofcrushing the coal in australia

Fosterville Gold Mine, Bendigo, Australia

The processing plant includes crushing, grinding, flotation, bacterial oxidation, and carboninleach (CIL) circuits The nominal capacity of the process plant is 2,275 tonnes per day (tpd) Its sulphide treatment plant is amongst leading BIOX systems in the world The run of mine (ROM) ore is reclaimed from stockpiles and fed to a bin and blendedJan 08, 2016 Introduction In Pit Crushing Conveying (IPCC)In Pit Crushing Conveying (IPCC) 1 Continuous mining is common in lignite soft coal mines for decades – loading using bucket wheel excavators, continuous haulage by conveyors, waste dump spreaders 22 In hard rock applications – truck and shovel is prevalent 31029312013, PRESENTATION, SANDVIK In Pit Crushing Client: Rio Tinto Coal Australia Rio Tinto Clermont Mine in Central Queensland uses an InPit Crushing and Conveying System (IPCC) for a major component of its overburden stripping for the mine The IPCC consists of a fully mobile sizing rig operating in the upper levels of the pit combined with, a ramp conveyor, 25km movable pivoting dump In Pit Crushing and Conveying (IPCC) Systems

Quarryturnedlandfill embraces inpit crushing solution

May 04, 2020 At this point, SBI’s crushing operations were being completely managed from within the pit – with a mobile circuit comprising the J50, a C44 tracked cone crusher, the R155 and a 6m x 15m S190 mobile screen The quarry was also in a state of transitionThe four inpit crushers from Germany have a crushing capacity of crushing 4,250t of ore an hour a unit The conveyer belt bearing crushed ore from the mine to the concentrate area is approximately 17km The main AG mill with 28MW gearless motors has a diameter of 122m and a length of 11mSino Iron Project, Cape Preston, Western Australia Apr 24, 2015 For waste, crushing takes place only to make the material transportable on the conveyor; for ore, inpit crushing is a part of the total comminution process Crushing waste rock in the pit has several benefits “If the waste rock has to be crushed, crushing it in the pit and conveying it out is the most economical solutionInpit crushing and conveying saves more than just fuel

InPit Crushing

Interest in inpit crushing and conveying (IPCC) technologies continues to grow and, with some flagship projects nearing completion, now seems a good time to review activity in the sector “The last year was good for new orders,” Thomas Jabs, senior vice president for mining at , told EMJThe existing inpit crushing system will be retained at least until the present concentrator is shut down and during this period a new semimobile inpit crushing plant will be installed in the northern section of the openpit, as well as a new crusher on the surface close to a stockpile feeding the 35km overland conveyor to the new concentratorNew Focus on InPit Crushing SystemsA minimum of 10 years handson experience in open pit mining, crushing, screening, Screening, crushing, washing, and sorting) Australia We are currently seeking applications from experienced HD Fitters familiar with Crushing Screening to work on our project TropicanaCrushing Screening Jobs (with Salaries) Indeed Australia

Determination of semimobile inpit crushing and conveying

Feb 12, 2021 Inpit crushing and conveying (IPCC) systems are currently receiving more attention as a result of the existing characteristics of openpit mining operations and what is likely to happen in the future The use of trucks and shovels for loading and hauling has been used as a dominant system in openpit and opencast mines due to their largescale operations compared with other mining methodsOct 18, 2018 Australian Gold, Victorian Golden Triangle, Gold Prospecting Creswick, GOPRO6,DIY Home made fire pit, Finding Gold, 4WD, Dog, Best Mate, Camping, 4K footage,Gold Prospecting Creswick Australia (Start of the gold Sizer in openpit mine Vostochny Based on the experiences of TAKRAF in coal crushers and crushing plants the first hard rock sizers for overburden of up to 200 MPa was successfully installed at the Vostochny mine to crush lumps of up to 2,500 mm down to a conveyable sizeSizers TAKRAF GmbH

First massive ThyssenKrupp inpit crusher successfully

Sep 15, 2011 Once in place and commissioned, each of the four inpit crushers will have the capacity to crush 4,250 t/h of magnetite, making it the largest inpit crushing system in Australia During operations, the crushers will be fed by 363 t Unit Rig MT6300 AC trucks, originally delivered by Mining but now part of The processing plant includes crushing, grinding, flotation, bacterial oxidation, and carboninleach (CIL) circuits The nominal capacity of the process plant is 2,275 tonnes per day (tpd) Its sulphide treatment plant is amongst leading BIOX systems in the world The run of mine (ROM) ore is reclaimed from stockpiles and fed to a bin and blendedFosterville Gold Mine, Bendigo, AustraliaThe impact of In Pit Crushing and Conveying (IPCC) equipment on pit shell optimization is a key element that is often overlooked in the early stages of mine planning Most of the analysis typically completed regarding IPCC is on the potential for cost reduction, whether in an attempt to improve a project’s economics, or to extend mine lifeIMPACT OF INPIT CRUSHING AND CONVEYING ON PIT

Axis Mineral Services — Crushing Screening, Ore Sorting

Crushing Screening, Ore Sorting and Civil Services for Australia's mining and civil industry Axis Mineral Services provide crushing for all requirements in Mining, Milling Processing and Civil applications, producing crushed rock for applications including