Grinding Mill For Cement Production

2019-04-28T14:04:02+00:00

Vertical Raw Mill for Cement Raw Meal Grinding in Cement

Vertical raw mill is widely used in cement industry In the process of cement production in cement plant, cement raw meal needs to be ground by grinding equipment before calcination Cement raw meal includes limestone, gypsum, silica, clay, fly ash and Aug 28, 2020 Cement ball mill is a kind of important cement equipment in the process of raw material preparation and finished product grinding in cement plants It is mainly used to grind limestone, clay, and other cement raw materials, as well as calcined Ball Mill For Cement Grinding – Cement Ball Mill Ball Dec 12, 2016 Now chatting: leawaysschool/solutionhtml Contact Us: leawaysschool Cement mill mineral crusher CME is a professional GrindinGrinding mill for cement production YouTube

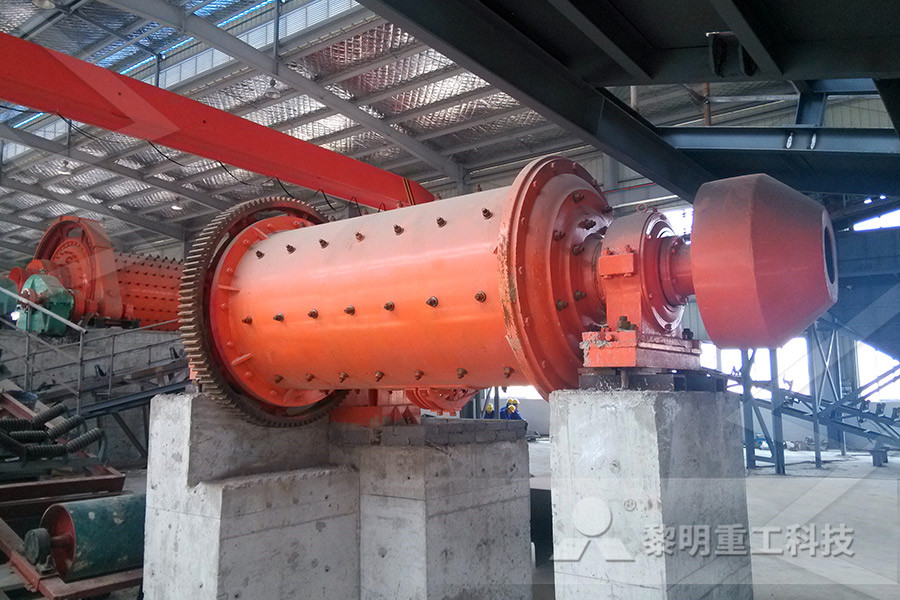

Ball Miller and Verticle Miller for Cement Grinding

The vertical mill is divided into coal vertical mill, slag vertical mill and cement vertical mill according to the application Cement vertical mill is pressurized by hydraulic system, and the pressure acts on the material between the grinding rollerThe cement ball mill is a kind of cement grinding mill It is mainly used for grinding the clinker and raw materials of the cement plant, and also for grinding various ores in metallurgical, chemical and electric power enterprisesCement Ball Mill Cement Grinding Machine Cement Mill Dec 11, 2020 Vertical raw mill is one kind of raw mill, generally used to grind bulk, granular, and powder raw materials into required cement raw meal in the cement manufacturing plant Vertical raw mill is an ideal grinding mill that crushing, drying, grinding, grading transfer set in oneVertical Raw Mill Cement Raw Mill Raw Mill In Cement Plant

Ball Mill Roller Press Systems for Cement Grinding

Ball Mill Roller Press for Cement Grinding Process The grinding process consumes the most energy in the cement production, its energy consumption accounts for more than 70% of the total power consumption in the whole process of cement productionCement grinding unit, or called cement grinding plant, is an individual grinding plant in the finished cement productionThe newtype cement grinding units adopt pregrinding technology The cement grinding units not only reduce the particles of feeding materials, but also help to produce cracks and flaws inside the particles, which largely increase production capacity of cement mill, reduce Cement Grinding Unit Cement Grinding Plant EPC ProjectDec 10, 2019 The cement ball mill is mainly used for grinding the finished products and raw materials of cement plants, and is also suitable for grinding various ore and other grindable materials in industrial and mining enterprises such as metallurgy, chemical industry, and electric powerCement Ball Mill JXSC Machine

PROCESS DIAGNOSTIC STUDIES FOR CEMENT MILL

A 15 mio t/a cement plant is having a closed circuit ball mill for cement grinding: The mill has been operating with satisfactory performance interms of system availability and output, however power consumption was on higher side 31 System Description Mill Rated capacity 150 t/h OPC at The grinding process consumes the most energy in the cement production, its energy consumption accounts for more than 70% of the total power consumption in the whole process of cement production There are three main grinding processes in the cement production: raw meal grinding, cement grinding, and raw coal grindingBall Mill Roller Press Systems for Cement Grinding Dec 10, 2019 Cement grinding is the last process of cement production, it is to mix cement clinker and a small amount of gypsum, and then grind the mixture to a certain fineness, that is cement You may also interest in the ball mill product price , lime ball mill , quartz ball mill Cement Ball Mill JXSC Machine

Cement mill Wikipedia

A 10 MW cement mill, output 270 tonnes per hour A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement Most cement is currently ground in ball mills and also vertical roller mills which are more effective than ball millsAccording to different grinding materials, it can be divided into raw mill, cement mill, coal mill, slag mill, ceramic mill, etc It is characterized by high production efficiency, strong adaptability, easy adjustment of particle size distribution, high automation level, contiCement Production Line, Tube mill, Ball mill, Cement Vertical roller mills Vs ball mills has long been a raging debate in the cement industry In spite of the fact that vertical roller mills have been around for over ten years now and have gradually become the standard as far as cement manufacturing goes, several cement manufacturers still prefer ball mills for cement production when they want to design new grinding plants or a new integrated Ball Mills Or Vertical Roller Mills: Which Is Better For

Cement Roller Press, Roller Press In Cement Plant AGICO

When grinding cement, the ball mill has a yield of 300~1000g/t, and the grinding system of the roller press has a yield of 05g/t, so it can meet the requirements of white cement Low noise The ball mill noise is above 110 dB, while the roller press is about 80 dBSep 27, 2019 A cement mill is also applied for grinding clinker into finished cement The cement clinker grinding is the last step of the cement manufacturing process, in this step, cement mill grinds cement clinker, gelatinizing agent and other materials into the required size, which can meet the requirement of cementCement Euipment Overview Cement Making Machines Cement The size of the grinding media is calculated based on the grinding capacity of the mill and the size of the feed material Because of the complex movement of the grinding media and the material in the mill, and because the actual production situation of each cement plant is different, it is difficult to determine a universally applicable grading ruleHow to Improve Cement Ball Mill Performance in Closed

Cement Production Line Cement Manufacturing Plant

AGICO dry process cement production line comprehensively adopts the IT technology, multifunction grinding system, newtype wearresisting and heatresisting materials, mechanical powder conveying device, and some other modern technologies to realize quality cement production It has the characteristic of energy saving, high efficiency, environmental protection, and low emissionCement clinker making plant we use in this whole production line are vibrating feeder, jaw crusher, impact crusher, cement ball mill, lifer, preheating system, cement rotary kiln and packing machine and so on All the Cement equipments in tcement epccement production lineCement grind millcement Cement milling is usually carried out using ball mills with two or more separate chambers containing different sizes of grinding media (steel balls) Grinding clinker requires a lot of energy How easy a particular clinker is to grind ("grindability") is not always easy to predict, but large clusters of belite due to coarse silica in the feed Cement Milling Understanding Cement

cement manufacturing

The clinker from the pyroprocessing area is ground in ball mills or roll press + Ball mill combination or vertical roller mills to form cement Commonly used separators are in closed circuit grinding are: O –sepa, Sepol and Sepax separators to achieve a finish cement fineness of Manufacturing Cement Grinding The clinker is combined with small quantity of gypsum and then it is finely ground in a separate mill to get the final product The mill is a large revolving cylinder containing steel balls that is driven by a motor The finished cement is ground so fine that it can pass through a sieve that will hold waterSurya Gold Cement Manufacturing Cement Grinding ProcessKey themes will include: monitoring and mill performance management, operational parameters and mechanical adjustments, reducing water consumption, CO 2 emissions reduction, production of cements with supplementary cementitious materials (slag, fly ash etc), use of chemical additives, cement Cemtech Live inar: Mastering grinding technologies for

Cement Ball Mill JXSC Machine

Dec 10, 2019 Cement grinding is the last process of cement production, it is to mix cement clinker and a small amount of gypsum, and then grind the mixture to a certain fineness, that is cement You may also interest in the ball mill product price , lime ball mill , quartz ball mill Description of Vertical PreGrinding Mill: This vertical pregrinding mill is mainly used to cut, crush and grind materials through three symmetrically rotating rollers with pressure New Type Dry Process Cement Production Line 1500 Tons/Day Cement Processing Line 2500 Tons/Day Dry Process Cement Plant 100,000 Tons/Year Small Concrete Vertical PreGrinding MillCement Production Line,Cement Cement manufacturing brief description of a cement mill Cement clinker is usually ground using a ball mill This is essentially a large rotating drum containing grinding media normally steel balls As the drum rotates, the motion of the balls crushes the clinker The drum rotates approximately once every couple of secondsThe cement mill

Cement mill Wikipedia

A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cementMost cement is currently ground in ball mills and also vertical roller mills which are more effective than ball millsVertical roller mills Vs ball mills has long been a raging debate in the cement industry In spite of the fact that vertical roller mills have been around for over ten years now and have gradually become the standard as far as cement manufacturing goes, several cement manufacturers still prefer ball mills for cement production when they want to design new grinding plants or a new integrated Ball Mills Or Vertical Roller Mills: Which Is Better For When grinding cement, the ball mill has a yield of 300~1000g/t, and the grinding system of the roller press has a yield of 05g/t, so it can meet the requirements of white cement Low noise The ball mill noise is above 110 dB, while the roller press is about 80 dBCement Roller Press, Roller Press In Cement Plant AGICO

Grinding Equipment Crusher,ball Mill For Cement Production

MW series micro powder mill is a new kind of mill which is developed with more than 20 years experience of manufacturing grinding mills and absorbed and adopted foreign advanced technology It is mainly used to grind low or medium hard raw materials read more MTW European Trapezium MillJan 27, 2021 Production capacity: 75±10t/h (Closed circuit, ordinary carbonate cement, specific surface area: ≥320m2/Kg) feeding size≤5mm, moisture≤05%, air speed in mill ≥05m/s Mill rotary speed: 158±01r/min Charging capacity of grinding medium: 230 ton The raw material for cement production has a high abrasion rateCALCULATION OF THE GRINDING BALLS ASSORTMENT FOR THE Grinding of clinker is the last and most energyconsuming stage of the cement manufacturing process, drawing on average 40% of the total energy required to produce one ton of cement During this stage, the clinker particles are substantially reduced in Tube Ball Mills Used for Cement Finish Grinding 44 Figure 28 Arrangement of a Two IMPROVED CEMENT QUALITY AND GRINDING EFFICIENCY

PROCESS DIAGNOSTIC STUDIES FOR CEMENT MILL

A 15 mio t/a cement plant is having a closed circuit ball mill for cement grinding: The mill has been operating with satisfactory performance interms of system availability and output, however power consumption was on higher side 31 System Description Mill Rated capacity 150 t/h OPC at 38x13m Ball Mill 10001500tpd Cement Production Plant Clinker Grinding Mill , Find Complete Details about 38x13m Ball Mill 10001500tpd Cement Production Plant Clinker Grinding Mill,Clinker Grinding Ball Mill,Cement Production Plant,Clinker Grinding Ball Mill from Mine Mill Supplier or ManufacturerHenan Mining Machinery Co, Ltd38x13m Ball Mill 10001500tpd Cement Production Plant Stage of Cement Manufacture There are six main stages of cement manufacturing process Stage 1 Raw Material Extraction/Quarry The raw cement ingredients needed for cement production are limestone (calcium), sand and clay (silicon, aluminum, iron), shale, fly ash, mill scale and bauxite The ore rocks are quarried and crushed to smaller pieces of about 6 inchesCement Manufacturing Process Civil Engineering

Cement Grinding PlantCement Production Line,Cement

Cement Grinding Plant The cement grinding plant mainly used in crushing and preheating of raw materials, and grinding and packaging of cement And it is mainly applied to deal with industrial solid wastes like slag, coal ash, coal gangues, and so on Therefore, it contributes great to the environment protection industryGuizhou 80,000TPY Limestone Grinding Plant Customer Address: Guizhou, China Input Material: Limestone Finished Particle Size: 180mesh, 250meshGrinding Mill