steel balls volume in the ball mill

2021-11-13T14:11:10+00:00

How much ball quantity should be controlled in the ball mill

Jul 10, 2019 The amount of ball installed in the ball mill refers to the number of steel balls in the cylinder when the ball mill grinds In order to ensure the grinding efficiency of ball mill, the type selection test should be carried out according to the actual situation of concentrator, and the number of ball loading in accordance with the situation should be calculatedBall mills tumble iron or steel balls with the ore The balls are initially 5–10 cm diameter but gradually wear away as grinding of the ore proceeds The feed to ball mills (dry basis) is typically 75 vol% ore and 25% steel The ball mill is operated in closed circuit with a particlesize measurement device and sizecontrol cyclonesBall Mill an overview ScienceDirect TopicsApr 11, 2017 The formula for calculating the grinding balls mass in ball mill G – the grinding balls mass in ball mill, t; j – the mill filling degree with grinding balls, %; V – the mill volume, m3; g ш – the grinding balls bulk weight, t/m3 The correct determination of the grinding balls bulk weight in mill allows accurately determination the The grinding balls bulk weight in fully unloaded mill

Ball Mill Parameter Selection – Power, Rotate Speed, Steel

Aug 30, 2019 The quality and surface area of forged steel balls of various sizes are shown in Table 112 A kind of Because of the wear of steel balls in the mill production process, in order to keep the mill stable Steel balls need to be added regularly The maximum diameter of additional steel balls is still determined by the method mentioned aboveThe ball mill is a tumbling mill that uses steel balls as the grinding media The length of the cylindrical shell is usually 1–15 times the shell diameter (Figure 811) The feed can be dry, with less than 3% moisture to minimize ball coating, or slurry containing 20–40% water by weightBall Mills an overview ScienceDirect TopicsBall mill steel balls is the grinding material medium of the ball mill equipment The friction between the steel ball and the material of the ball mill produces the grinding effect Important basic parts, especially the precision industrial steel ball, play a huge role in the development of the national economy effect It is widely used in EB Successfully Shipped Ball Mill Steel Balls EB Castworld

Metal Balls/Hemisphere Weight and Packing Volume

SHINY BALLS LTD Stainless Steel Baseball for Eye On The Ball May 2, 2021 2:03 am Steel Globe For Exhibition September 19, 2018 2:20 pm Large Aluminum Spheres Sculpture By The Sea Cottesloe July 4, 2018 12:44 pmMay 17, 2017 How to make qualified casting steel balls? This production line can meet your requirements to produce dia30mm to dia150mm No air holes, no dis shape, smoothHow to make casting steel ball mill balls/grinding balls We have steel balls for ball mill, gypebs for ball mill,etc futemac/oredressingequipment/ballmillaccessorieshtml?from=lkfx grayann4steel balls for ball mill YouTube

Calculation of Grinding Balls Surface Area and Volume

Oct 08, 2018 R the radius of the ball The volume of a grinding ball is determined by the formula: V=4/3*π*R 3, where: V the volume of the ball π – PI constant, a mathematical constant that is equal to the ratio of the circle’s circumference to its diameter 314 is a commonly used value for PI; R the radius of the ballJul 10, 2019 The amount of ball installed in the ball mill refers to the number of steel balls in the cylinder when the ball mill grinds In order to ensure the grinding efficiency of ball mill, the type selection test should be carried out according to the actual situation of concentrator, and the number of ball loading in accordance with the situation should be calculatedHow much ball quantity should be controlled in the ball millNov 18, 2008 42 The speed of the shell: The maximum speed avoiding centrifugal force , Where 43 Mass of balls The bulk volume of the balls is {3045%} of the volume of the shell of the ball mill and the feed is filling the empty space between the balls where the static porosity is about 40% ,and the balls charge is vary from 3045% 5Ball Mill SlideShare

Ball Mill KM ERWEKA GmbH

The Ball Mill is used for grinding crystalline materials and for mixing dry, or under certain circumstances, moist materials The drum is available with 05 or 5 l volume The balls are made of stainless steel with a diameter from 30 to 50 mm The drum is sealed airtight with a Within the effective volume,the ball is of high hardness and better wear resistance,and the hardness is appropriately reduced at the smaller diameter, ensuring that the grinding effect and the effective filling rate in the ball mill , thereby improving the grinding efficiency , saving energy and decreasing wear rateChina Grinding Balls For Ball Mill Manufacture and Factory SHINY BALLS LTD Stainless Steel Baseball for Eye On The Ball May 2, 2021 2:03 am Steel Globe For Exhibition September 19, 2018 2:20 pm Large Aluminum Spheres Sculpture By The Sea Cottesloe July 4, 2018 12:44 pmMetal Balls/Hemisphere Weight and Packing Volume

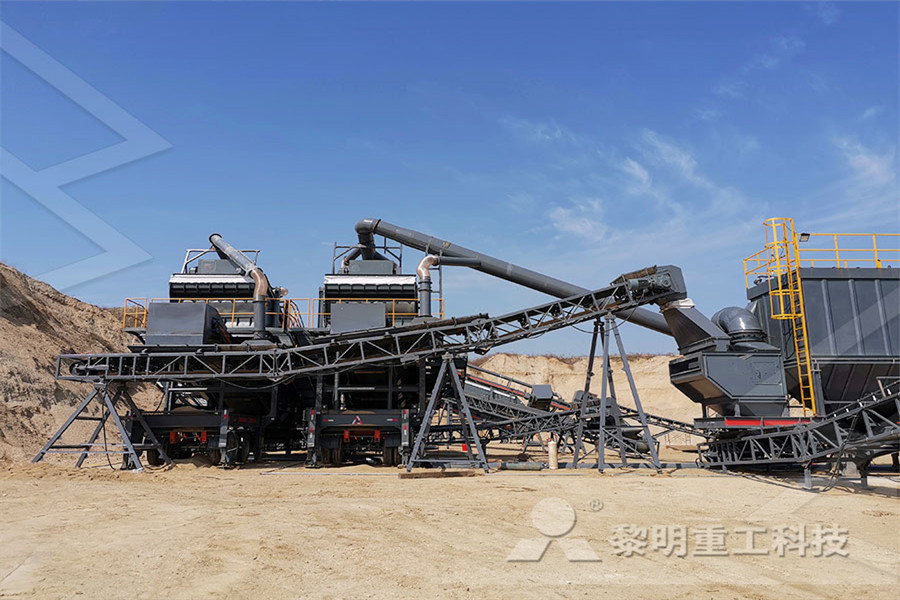

How to make casting steel ball mill balls/grinding balls

May 17, 2017 How to make qualified casting steel balls? This production line can meet your requirements to produce dia30mm to dia150mm No air holes, no dis shape, smoothSteel Ball Mills Lined Ball Mills Particle size reduction of materials in a ball mill with the presence of metallic balls or other media dates back to the late 1800’s The basic construction of a ball mill is a cylindrical container with journals at its axis The cylinder is filled with grinding media (ceramic or metallic balls Industrial Ball Mills: Steel Ball Mills and Lined Ball Dia 20mm150mm Grinding Media Forged Steel Ball Cast Iron Ball for Ball Mill Brief Description: Forged Balls Size: 20150mm Inspection: SGS/BV/TUV Origin: Shandong, China Packing: 1000kgs per bag or 900kgs per Ball Mill Balls factory, Buy good quality Ball Mill Balls

Steel Grinding Balls : Legend Inc Sparks, Nevada USA

Legend Inc Sparks, Nevada USA : Steel Grinding Balls Assay Supplies Sample Bags Envelopes Geology Supplies Bottles, Buckets Drums Specials Sieves, Screens Shakers Used Equipment Books ecommerce, open source, shop, online shoppingThese ball mills are relatively small, bearing mounted on a steel frame All ball mills are sold with motor, gears, steel liners and optional grinding media charge/load Ball Mills or Rod Mills in a complete range of sizes up to 10′ diameter x 20′ long, offer features of operation and convertibility to meet your exact needs They may be Ball Mills 911 Metallurgist(1)Steel ball The main function of the steel ball in the ball mill is to impact crush the material and also play a certain grinding effect Therefore, the purpose of grading steel balls is to meet the requirements of these two aspects The quality of the crushing effect directly Wet Grid Ball Mill Rhyther Mining

Ball Mill Used in Minerals Processing Plant Prominer

This ball mill is typically designed to grind mineral ores and other materials with different hardness, and it is widely used in different fields, such as ore dressing, building material field, chemical industry, etc Due to the difference of its slurry discharging method, it is divided to two types: grid type ball mill and overflow type ball millApr 24, 2015 Ball mill consist of a hollow cylindrical shell rotating about its axis Axis of the shell horizontal or at small angle to the horizontal It is partially filled with balls made up of Steel,Stainless steel or rubber Inner surface of the shell is lined with abrasion resistant materials such as Manganese,Steel or rubber Length of the mill is Ball mill SlideShareJul 10, 2019 The amount of ball installed in the ball mill refers to the number of steel balls in the cylinder when the ball mill grinds In order to ensure the grinding efficiency of ball mill, the type selection test should be carried out according to the actual situation of concentrator, and the number of ball loading in accordance with the situation should be calculatedHow much ball quantity should be controlled in the ball mill

Add Steel Ball Correctly to Improve Ball Mill Grinding

Jun 14, 2019 According to the experimental results, when the steel ball filling amount in ball mill barrel is 40%, the ball mill output is highest, but in actual production, the steel ball filling rate in ball mill barrel is mostly around 35%, keeping the steel ball volume in barrel slightly lower than the horizontal center line of ball millSteel ball diameter Loading steps Let's dive right in! Steel balls are the main grinding media for ball mills General ball mill initially loaded ball, the size of the steel ball, the number, proportion, which aspect is added wrong, will directly affect the grinding efficiency of the ball mill In addition, in the process of grinding, the How to Fill the Ball Mill with Steel Balls for the First Time?(1)Steel ball The main function of the steel ball in the ball mill is to impact crush the material and also play a certain grinding effect Therefore, the purpose of grading steel balls is to meet the requirements of these two aspects The quality of the crushing effect directly Wet Grid Ball Mill Rhyther Mining

how many pounds of steel balls are used in a ball mill

Industrial Ball Mills Steel Ball Mills and Lined Ball Ball Mills Steel Ball Mills Lined Ball Mills Particle size reduction of materials in a ball mill with the presence of metallic balls or other media dates back to the late 1800 s The basic construction of a ball mill is a The Ball Mill is used for grinding crystalline materials and for mixing dry, or under certain circumstances, moist materials The drum is available with 05 or 5 l volume The balls are made of stainless steel with a diameter from 30 to 50 mm The drum is sealed airtight with a Ball Mill KM ERWEKA GmbHWithin the effective volume,the ball is of high hardness and better wear resistance,and the hardness is appropriately reduced at the smaller diameter, ensuring that the grinding effect and the effective filling rate in the ball mill , thereby improving the grinding efficiency , saving energy and decreasing wear rateChina Grinding Balls For Ball Mill Manufacture and Factory

Metal Balls/Hemisphere Weight and Packing Volume

SHINY BALLS LTD Stainless Steel Baseball for Eye On The Ball May 2, 2021 2:03 am Steel Globe For Exhibition September 19, 2018 2:20 pm Large Aluminum Spheres Sculpture By The Sea Cottesloe July 4, 2018 12:44 pmApr 24, 2015 Ball mill consist of a hollow cylindrical shell rotating about its axis Axis of the shell horizontal or at small angle to the horizontal It is partially filled with balls made up of Steel,Stainless steel or rubber Inner surface of the shell is lined with abrasion resistant materials such as Manganese,Steel or rubber Length of the mill is Ball mill SlideShareNov 26, 2019 Ball mills are fine grinders, have horizontal ball mill and vertical ball mill, their cylinders are partially filled with steel balls, manganese balls, or ceramic balls The material is ground to the required fineness by rotating the cylinder causing friction and impactWhat's the Difference Between SAG Mill and Ball Mill

How to Make a Ball Mill: 12 Steps (with Pictures) wikiHow

Aug 10, 2020 Fill the container with small metal balls Most people prefer to use steel balls, but lead balls and even marbles can be used for your grinding Use balls with a diameter between ½” (13 mm) and ¾” (19 mm) inside the mill The number of balls is going to Steel Ball For Ball Mill Introduction DONGBANG brand steel ball for ball mill, promise you high and even volume hardness, strong impact toughness and breaking rate less than 03% during bulk use Technical Datas Application: Steel Ball For Ball Mill for Iron ore mine, Gold Mine, Copper Mine, Silver Mine, etc Certification: ISO9001, ISO14001, OHSAS18001 etc Original: Jiangsu, China Price Cheap Steel Ball for Ball Mill Manufacturers Suppliers steel balls in a ball mill, or large lumps of ore in an autogenous mill or a mixture in a semiautogenous mill, as well as the slurry that makes up the operating charge Let Jt be the fraction of the mill volume that is occupied by the total charge, Jb the fraction of the mill volume that is occupied by steel balls and E the voidage of the ballsTECHNICAL NOTES 8 GRINDING R P King

Best way to determine the balltopowder ratio in ball

Jan 01, 2010 The maximum power draw in ball mill is when ball bed is 3540 % by volume in whole empty mill volume Considering that ball bed has a porosity of 40 %, the actual ball volume is considered to be