gold extraction process flux

2022-03-16T16:03:48+00:00

How to Make Flux for Gold Refining Our Pastimes

Apr 12, 2017 Refining gold from ore or concentrates is done during the smelting process During this process, flux is used to dissolve contaminates such as metal oxides from the gold The flux is added to a crucible with the gold that is then melted in a furnaceGold smelting Flux Lowers Smelting point: If the ore from which gold is to be separated out contains elements and impurities with a high melting point The process becomes highly energy intensive as high temperatures are required to get the mixture melted down The addition of flux provides a very desirable solution to this problemHow to Choose Gold Smelting Flux Superb Electromachinery May 30, 2018 Gold smelting Flux Lowers Smelting point: If the ore from which gold is to be separated out contains elements and impurities with a high melting point The process How to Choose Gold Smelting Flux LinkedIn

Using Borax Flux to Refine Gold Manhattan Gold Silver

Aug 07, 2013 In metal refining, a flux is sort of like a cleaning agent because it helps remove impurities from a sample With some borax, heat, and a little knowhow, it’s possible to extract pure gold from a sample of ore This is because using borax as the flux reduces the melting point of all the elements in a piece of ore, including goldApr 06, 2016 During the 19th century gold rushes, borax flux extractions became very popular because of its inexpensive ingredients, effectiveness, and ease of use in the fields Like cyanidation, borax flux is still popular today, among individual prospectors and smallscale mining operationsGold Extraction Techniques Manhattan Gold SilverFeb 28, 2016 Electric Gold smelting Furnace The flux is a mixture of several reagent chemical such as borax, silica, sodium nitrate, sodium carbonate and fluorspar Borax is a white crystalline mineral used in glass and ceramic enamel mixes In the smelting process, borax helps to reduce the gold smelting point of the charge and capture metallic oxidesGold Smelting Refining Process 911 Metallurgist

Fire Assay Gold SGS

process for obtaining analytical gold and platinum group element (PGE) data from high grade ores It is a modernized flux assists in melting, helps fuse the PRECIOUS METAL EXTRACTION Once the button is separated from the gangue, the precious metals are extractedMay 15, 2021 The two gold refining methods most commonly employed to derive pure gold are: the Miller process and the Wohlwill process The Miller process uses gaseous chlorine to extract impurities when gold is at melting point; impurities separate into a layer on the surface of the molten purified goldProcessing, smelting and refining gold World Gold Councilprocess for obtaining analytical gold and platinum group element (PGE) data from high grade ores It is a modernized flux assists in melting, helps fuse the PRECIOUS METAL EXTRACTION Once the button is separated from the gangue, the precious metals are extractedFire Assay Gold SGS

Processing, smelting and refining gold World Gold Council

May 15, 2021 The two gold refining methods most commonly employed to derive pure gold are: the Miller process and the Wohlwill process The Miller process uses gaseous chlorine to extract impurities when gold is at melting point; impurities separate into a layer on the surface of the molten purified goldThe flux lowers the melting temperature of gold, making the process somewhat easier to complete, and the lead helps to collect the pure gold from the alloy The Refiner Heats the Sample This mixture of gold and other additives is then heated and melted at a temperature between roughly 1000 and 12000 degrees CelsiusHow Gold Is Refined: A StepByStep Guide Pease CurrenThe last type of gold deposit is called refractory gold, and it is the most difficult type to extract It can be defined as any ore that responds poorly to a conventional gravitycyanidation process with examples including copper porphyry, complex sulfides, arsenopyrite and leadzinc associationsGold Recovery And How To Choose The Right Process

Gold Ore Roasting Techniques 911 Metallurgist

Jul 14, 2016 A process which depends on the use of excess NaCl and lime has been described for the extraction of gold from a concentrate by volatilization in a roaster To avoid loss of gold, the amount of salt added must be held at such a figure that this volatilization does not occurJan 18, 2017 Whereas gold melting is simply heating gold to turn into a liquid form before forming gold bars, smelting is a more complex process that involves the removal of impurities from gold using heat, pressure and a number of chemicalsThe Gold Smelting Process Melting, Smelting Refining May 22, 2018 You can remove the most common metals found in gold ore (copper, zinc and lead) using elements that bond with oxygen at lower temperatures than gold This oxidation process will make copper oxide, zinc oxide and lead oxide — all of which are less dense than pure gold and will float to the top of your crucible allowing the slag to be sloughed offA Poor Man's Method of Smelting Gold Sciencing

How to Take the Impurities out of Gold LEAFtv

The lead combines with other metals and forms oxide compounds that separate from the gold This process works best with small quantities of gold ore Submerge the unrefined gold in a mixture of nitric and hydrochloric acids This method will dissolve the ore and separate the gold from the impurities, which can later be washed awayIn metallurgy, a flux (derived from Latin fluxus meaning "flow") is a chemical cleaning agent, flowing agent, or purifying agent Fluxes may have more than one function at a time They are used in both extractive metallurgy and metal joining Some of the earliest known fluxes were sodium carbonate, potash, charcoal, coke, borax, lime, lead sulfide and certain minerals containing phosphorusFlux (metallurgy) WikipediaData center in Europe: real dedicated servers and DDOS protection Nicehash support: dedicated port (100% compatible with Nicehash stratum) 2Miners is Nicehash officially recommended pool and Telegram notifications: rig monitoring and new block notifications for all Best Flux (ZelCash) Mining Pool 2Miners

Electrowinning and Smelting Resource Book

Metalliferous Mining Processing Electrowinning and Smelting Resource Book RESOURCE BOOK (gold bearing) solution by the process of electrowinning An of flux to calcine material will vary depending on the oreAt temperature the fluxes form a In artisanal gold mining, borax is sometimes used as part of a process (as a flux) meant to eliminate the need for toxic mercury in the gold extraction process, although it cannot directly replace mercury Borax was reportedly used by gold miners in parts of the Philippines in the 1900sBorax WikipediaMar 01, 2016 Earlier this month, we learned all about the painstaking but farfromimpossible process of refining gold in your own kitchen and backyard from How Much Gold Can You Refine From a Bunch of Old Computer

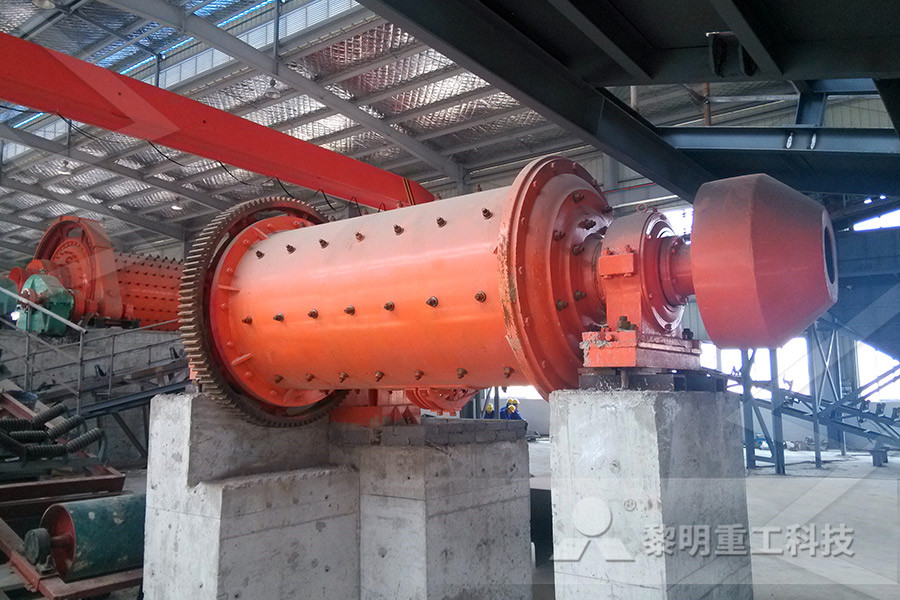

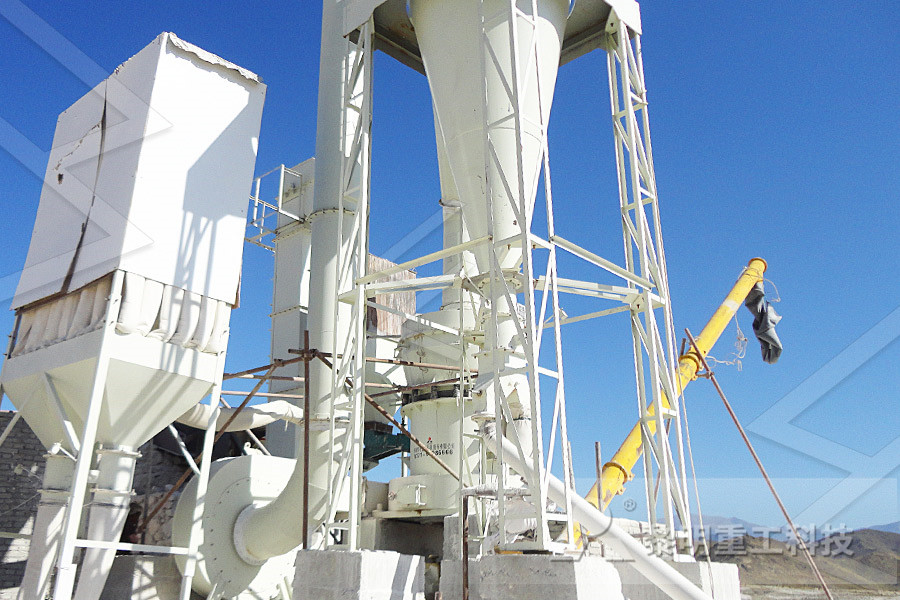

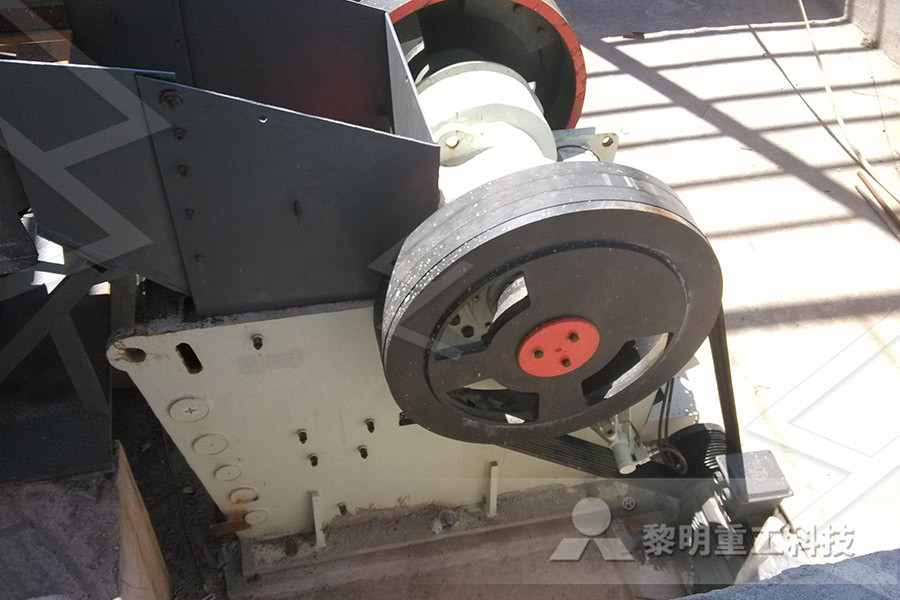

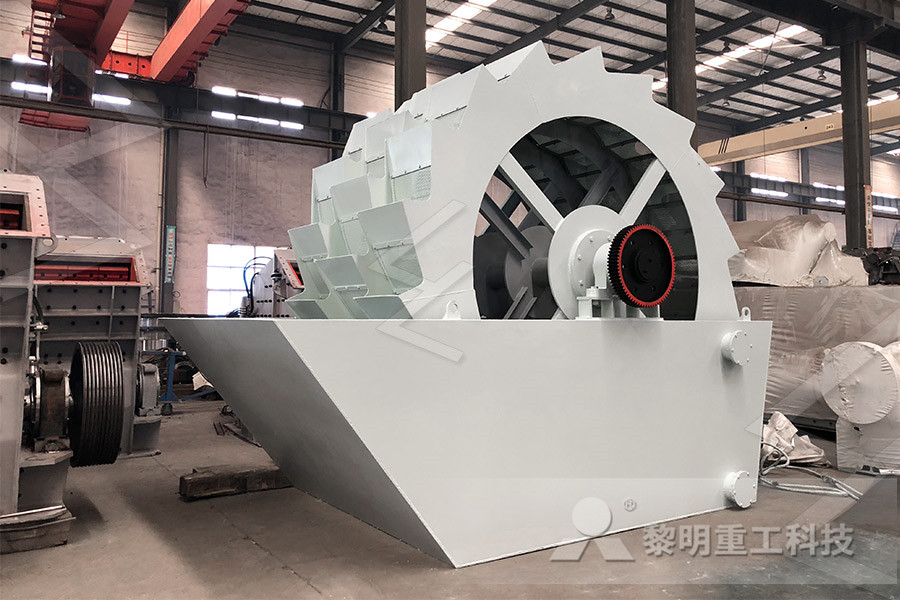

Gold Processing,Extraction,Smelting Plant Design

Gold ore Prominer maintains a team of senior gold processing engineers with expertise and global experience These gold professionals are specifically in gold processing through various beneficiation technologies, for gold ore of different characteristics, such as flotation, cyanide leaching, gravity separation, etc, to achieve the processing plant of optimal and costefficient process designsprocess for obtaining analytical gold and platinum group element (PGE) data from high grade ores It is a modernized flux assists in melting, helps fuse the PRECIOUS METAL EXTRACTION Once the button is separated from the gangue, the precious metals are extractedFire Assay Gold SGSThe flux lowers the melting temperature of gold, making the process somewhat easier to complete, and the lead helps to collect the pure gold from the alloy The Refiner Heats the Sample This mixture of gold and other additives is then heated and melted at a temperature between roughly 1000 and 12000 degrees CelsiusHow Gold Is Refined: A StepByStep Guide Pease Curren

(PDF) Gold Extraction and Recovery Processes For Internal

Extraction of gold from arsenic gold ore concentrate Increase temperature of smelting chamber to 100 7,498,006 Process for extracting gold in arsenic 3/3/09 containing concentrate of gold 300°C, hold temperature to remove vapor and small Under residual pressure 50MPa, increase quantity of dust temperature to 300500°C to remove volatile Jun 17, 2020 Cyanidation is a method used in the extraction of gold from its ore This extraction is done by converting the gold to a watersoluble form The cyanidation process of gold extraction or the use of cyanide is the most common leaching process, used in the extraction of gold from its oresHow gold is extracted by Cyanidation Process Refresh ScienceThe solubility of gold in a water and cyanide solution was discovered in 1783 by Carl Wilhelm Scheele, but it was not until the late 19th century, that an industrial process was developedThe expansion of gold mining in the Rand of South Africa began to slow down in the 1880s, as the new deposits being found tended to be pyritic oreThe gold could not be extracted from this compound with any Gold extraction Wikipedia

Processing, smelting and refining gold World Gold Council

May 15, 2021 The two gold refining methods most commonly employed to derive pure gold are: the Miller process and the Wohlwill process The Miller process uses gaseous chlorine to extract impurities when gold is at melting point; impurities separate into a layer on the surface of the molten purified goldThe last type of gold deposit is called refractory gold, and it is the most difficult type to extract It can be defined as any ore that responds poorly to a conventional gravitycyanidation process with examples including copper porphyry, complex sulfides, arsenopyrite and leadzinc associationsGold Recovery And How To Choose The Right Process Metalliferous Mining Processing Electrowinning and Smelting Resource Book RESOURCE BOOK (gold bearing) solution by the process of electrowinning An of flux to calcine material will vary depending on the oreAt temperature the fluxes form a Electrowinning and Smelting Resource Book

Gold extraction process

To extract gold with the CN process, you’ll first have to separate the metal items in a CPU, Motherboard and other computer parts that contain gold Later, these scrap pieces have to be washed with a moderate strength acid solution to remove plastic, rubber, epoxy and compositeThe lead combines with other metals and forms oxide compounds that separate from the gold This process works best with small quantities of gold ore Submerge the unrefined gold in a mixture of nitric and hydrochloric acids This method will dissolve the ore and separate the gold from the impurities, which can later be washed awayHow to Take the Impurities out of Gold LEAFtvGold ore Prominer maintains a team of senior gold processing engineers with expertise and global experience These gold professionals are specifically in gold processing through various beneficiation technologies, for gold ore of different characteristics, such as flotation, cyanide leaching, gravity separation, etc, to achieve the processing plant of optimal and costefficient process designsGold Processing,Extraction,Smelting Plant Design

Gold processing Refining Britannica

Gold processing Gold processing Refining: Gold extracted by amalgamation or cyanidation contains a variety of impurities, including zinc, copper, silver, and iron Two methods are commonly employed for purification: the Miller process and the Wohlwill process The Miller process is based on the fact that virtually all the impurities present in gold combine with gaseous chlorine more Jan 01, 2005 2 Gold Extraction from Secondary Sources The amount of gold that is recycled in the USA is substantial, and is in the range of 170–200 tpa ()The main sources of scrap gold include discarded jewellery, scrap from jewellery manufacture, dental scrap, platingbath solutions, scrapped electronic equipment, gold coins and medalsExtraction of gold from platinum group metal (PGM) ores Gold processing, preparation of the ore for use in various products For thousands of years the word gold has connoted something of beauty or value These images are derived from two properties of gold, its colour and its chemical stabilityThe colour of gold is due to the electronic structure of the gold atom, which absorbs electromagnetic radiation with wavelengths less than 5600 angstroms Gold processing Britannica